In the world of modern printing technology, **UV Direct-to-Film (DTF)** stands out as an innovative alternative to traditional printing methods. This cutting-edge technique utilizes ultraviolet light to cure inks, allowing for vibrant prints on a variety of substrates—including those that were once deemed unsuitable for conventional methods. Businesses are increasingly turning to UV DTF for its eco-friendly benefits, impressive color quality, and versatility, making it a formidable competitor in the printing landscape. As the demand for enhanced printing solutions rises, understanding the advantages of UV DTF become essential for modern enterprises. This article will navigate through the benefits and challenges of UV DTF in comparison to established printing practices, guiding business owners towards informed choices that can reshape their operations.

When considering the advancements in printing technologies, the term **UV Direct-to-Film (DTF)** may not be the only phrase that comes to mind. Some might refer to this method as ultraviolet printing on film, celebrating its unique capacity to produce vivid images and patterns. As industries seek dynamic and environmentally-friendly printing solutions, the spotlight now shines on alternatives like UV DTF, which combines the efficiency of modern technology with high-quality outputs. This exploration will delve into various aspects of this innovative printing process, contrasting its strengths and weaknesses against those of traditional techniques such as inkjet and offset printing. By embracing UV DTF, businesses can not only enhance their product offerings but also align with the growing eco-conscious market.

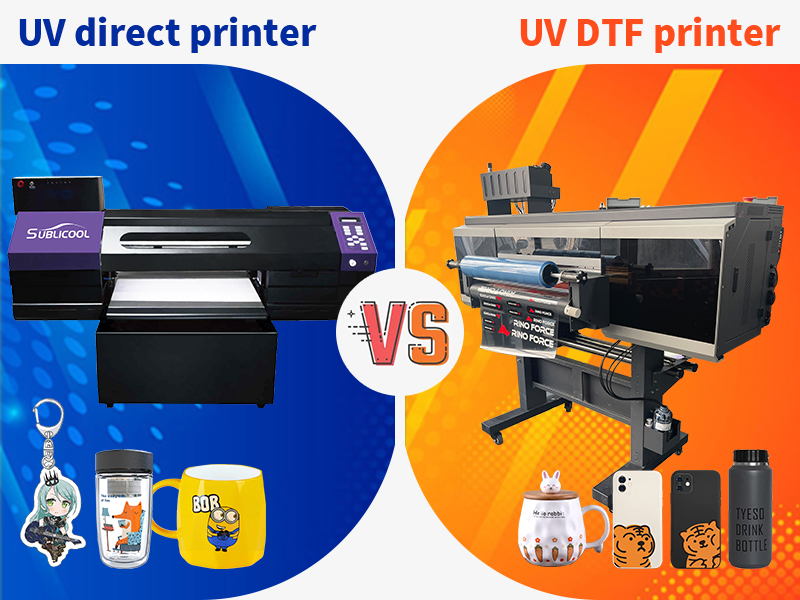

Understanding UV DTF Printing Technology

UV Direct-to-Film (DTF) printing is a revolutionary technique that harnesses the power of ultraviolet light to cure inks directly onto a special film. This advanced method allows businesses to create high-quality prints that can be transferred onto a variety of substrates, including tricky surfaces like glass, metal, and plastics. As demand for innovative and versatile printing methods continues to rise, UV DTF has quickly become a frontrunner in the printing industry.

The key advantage of UV DTF printing lies in its ability to deliver stunning color vibrancy and intricate detail. Traditional printing methods often struggle to achieve such precision on non-porous materials, making UV DTF a preferred choice for businesses needing to cater to diverse client needs. This capability ensures that brands stand out with eye-catching designs that engage consumers effectively.

Advantages of UV DTF Over Traditional Printing Methods

UV DTF printing offers several compelling advantages compared to traditional printing methods. One of the most noteworthy is its eco-friendly nature, as it uses UV-cured ink which emits fewer volatile organic compounds (VOCs) than solvent-based inks commonly used in traditional methods. This reduction in harmful emissions not only benefits the environment but also aligns with the growing consumer preference for sustainable practices.

Additionally, the versatility of UV DTF means that businesses can explore a broader range of substrates than ever before. While traditional printing is often limited to porous materials, UV DTF enables printing on surfaces that many businesses may not have previously considered. This opens up new avenues for product offerings and allows for innovative marketing strategies.

Cost Considerations for UV DTF Printing Equipment

Investing in UV DTF printing equipment may require a larger initial capital outlay compared to traditional printing setups. However, savvy business owners recognize that this investment can lead to significant cost savings in the long run. UV DTF technology typically results in less ink waste and fewer printing errors, ultimately contributing to a lower overall expenditure.

Moreover, as demand for high-quality, customizable prints continues to grow, businesses that adopt UV DTF can improve their profit margins by offering unique products that cannot be easily replicated using traditional methods. Therefore, while the upfront expense may be daunting, the long-term financial benefits and revenue opportunities make it a worthwhile consideration.

Challenges of Implementing UV DTF Printing

Despite the many benefits of UV DTF printing, businesses may encounter challenges during its implementation. The initial learning curve can be steep for operators who are unfamiliar with the technology. Training staff to utilize UV DTF printers optimally is crucial; thus, companies must allocate time and resources to equip their teams with the necessary skills.

Another consideration is the maintenance and servicing of UV printing equipment. Unlike traditional printers, UV DTF machines may require specialized help for repairs and maintenance, potentially leading to increased downtime if problems arise. Businesses need to account for these factors when deciding whether to transition to UV DTF printing.

Comparing Production Speed between UV DTF and Traditional Methods

One of the standout features of UV DTF printing is its rapid production speed. Because the process employs instant curing, prints are ready for handling almost immediately, allowing businesses to meet tight deadlines more effectively than traditional methods, which may require longer drying times. This efficiency can be particularly advantageous during peak seasons or for fulfilling large orders.

In contrast, traditional printing methods often involve multiple steps that can slow down output, increasing labor costs and typical turnaround times. By adopting UV DTF printing, businesses can optimize their production processes and remain competitive in today’s fast-paced market, ultimately ensuring customer satisfaction with timely deliveries.

The Future of UV DTF Printing in Business

As the printing market continues to evolve, UV DTF printing technology shows promising signs of growth and adaptability. With advancements in UV printing technology, manufacturers are consistently improving equipment efficiency, making, even higher-quality prints more accessible to businesses of all sizes. This accessibility may further encourage companies to explore UV DTF as a viable option for their printing needs.

The ongoing pursuit of sustainability will also play a pivotal role in promoting UV DTF printing in the business landscape. Companies increasingly prioritize environmentally conscious options that minimize their ecological footprint. As more brands recognize the advantages of UV DTF, which includes less waste and energy consumption, we are likely to witness a shift in market preferences favoring this innovative printing technology.

Frequently Asked Questions

What is UV DTF printing and how does it differ from traditional printing methods?

UV Direct-to-Film (DTF) printing is a modern technique that uses ultraviolet light to cure ink onto film for transfer to various surfaces. Unlike traditional printing methods that often require solvent-based inks and a heat press, UV DTF offers a more eco-friendly and efficient process, allowing for vibrant color reproduction and versatility across different substrates.

Are UV DTF printers more environmentally friendly compared to traditional printing methods?

Yes, UV DTF printers are considered more environmentally friendly as they use UV-cured inks that emit fewer harmful solvents and reduce waste during production. This aligns with the growing demand among businesses for sustainable printing solutions.

What types of surfaces can UV DTF printing effectively work on compared to traditional methods?

UV DTF printing excels in versatility as it can print on a wide variety of surfaces, including non-porous materials like metal, glass, and acrylic. Traditional printing methods, on the other hand, are often limited to fabric or porous substrates.

How does the durability of prints from UV DTF compare to those from traditional printing methods?

Prints produced using UV DTF technology are generally more durable and resistant to scratching and fading compared to those from traditional methods. This makes UV DTF particularly advantageous for high-wear items.

What are the cost implications of switching from traditional printing methods to UV DTF?

While the initial cost of UV DTF printers can be higher than traditional printers, the long-term savings come from reduced consumable costs and lower waste, potentially making UV DTF a more cost-effective solution for businesses over time.

How does the production speed of UV DTF printing compare to traditional printing techniques?

UV DTF printing typically offers faster production speeds due to its quick curing process, allowing businesses to meet tight deadlines and high-demand periods more effectively than with traditional printing methods.

| Criteria | UV DTF Printing | Traditional Printing |

|---|---|---|

| Environmental Impact | Low waste with UV-cured inks, eco-friendly | Higher emissions with solvent-based inks |

| Versatility | Can print on various surfaces including metal and glass | Limited to porous surfaces and fabrics |

| Color Quality | Delivers vibrant colors and intricate details | May not achieve the same level of vibrancy |

| Ease of Use | Simplifies printing process without heat press | Requires heat press for application |

| Cost Efficiency | Higher initial investment but lower long-term costs | Lower upfront cost but higher operational expenses |

| Production Speed | Faster turnaround time due to quick curing | Longer production times due to ink drying |

| Creative Possibilities | Enables customized and creative applications | Limited creative flexibility compared to UV DTF |

Summary

UV DTF printing is revolutionizing the printing industry with its numerous advantages including environmental sustainability, vibrant color reproduction, and versatility in printing on various surfaces. By reducing waste and allowing for quick production, UV DTF emerges as an efficient alternative to traditional methods. Businesses looking to enhance their printing capabilities and minimize their ecological footprint will find that UV DTF not only meets their immediate printing needs but also opens avenues for creative possibilities and expansion in product offerings.