UV DTF transfer opens new possibilities for garment customization by combining digital precision with lasting durability. It uses UV-curable inks that cure quickly, delivering vibrant garment transfers on a wide range of fabrics. When you choose UV DTF transfer, you gain sharp detail, excellent color saturation, and strong wash-fastness across common garments. This approach aligns with UV DTF printing and DTF transfer workflows to produce durable garment prints that resist cracking and fading after repeated washes, especially with heat press curing for DTF. With proper ink selection, compatible film, and precise curing, you can scale from small runs to production lines while preserving design fidelity.

Beyond the label UV DTF transfer, this approach is commonly described as a UV-based direct-to-film (DTF) process, where UV-curable inks print onto a transfer film and then bond to fabric through heat and pressure. Viewed through an LSI lens, related terms include UV printing on fabric, direct-to-film transfers, durable textile graphics, and vibrant heat-pressed results, all pointing to the same core technique. The method emphasizes long-lasting adhesion, color fidelity on both light and dark substrates, and compatibility with a range of garment materials. While staying faithful to the original workflow, practitioners often discuss underbases, proper curing, and post-press finishing as interchangeable ideas expressed in different language. If you’re evaluating options, consider how each term reflects the same durable, color-rich outcome you can achieve with a well-tuned UV-directed transfer process.

1) Understanding UV DTF transfer: foundation for durable, vibrant garments

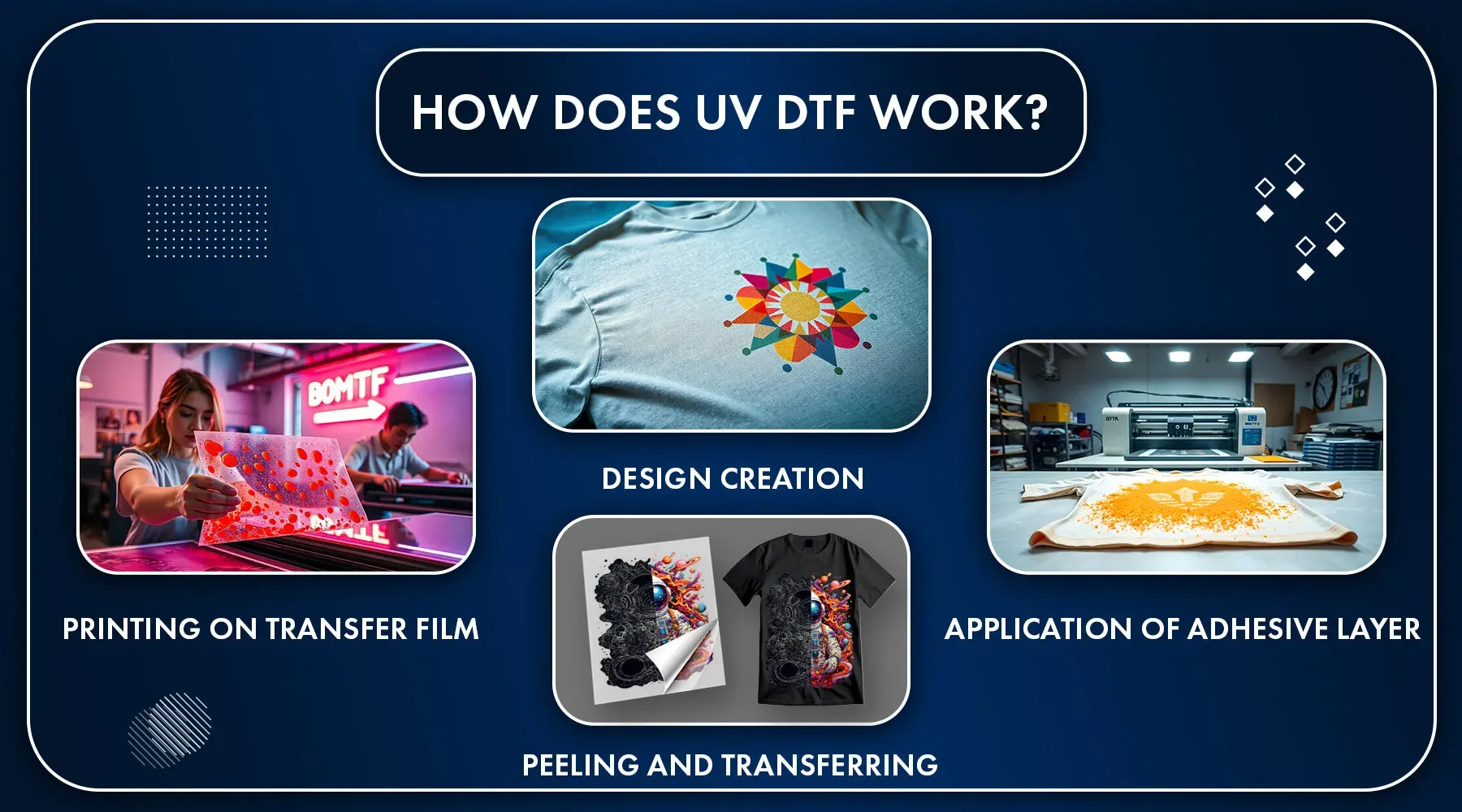

UV DTF transfer uses UV-curable inks on a transfer film that is applied to fabric with a heat press. This combination lets designers achieve crisp detail and bold color across a range of fabrics, while leveraging the efficiency of digital workflows. In the process, the ink cures quickly, either through UV light or the heat press, helping to lock in details and color for durable garment prints.

From a practical perspective, UV DTF printing lays the groundwork for vibrant garment transfers by marrying precision with robust adhesion. The right ink, film, adhesive powder, and curing method are essential to ensure the finished result withstands washing and wear, making this approach a strong option for both small runs and larger productions.

2) UV DTF printing vs traditional DTF transfer: choosing the best path for durability

Compared with traditional DTF transfer, UV DTF printing often offers a broader color gamut, sharper edges, and better performance on dark fabrics due to the potential for a white underbase. This combination enhances color saturation and detail retention, which is crucial for durable garment prints and faithful logo reproduction.

To optimize longevity, it’s important to align the curing method with the fabric and ink system. Heat press curing for DTF can provide the necessary adhesion when UV-curable inks are used, ensuring that vibrant garment transfers resist cracking, fading, and edge wear through repeated washes.

3) Essential materials and equipment for UV DTF transfers

A reliable UV DTF transfer workflow starts with quality UV DTF film and adhesive powder, paired with UV-curable inks and a printer designed for this ink family. Selecting compatible components helps ensure clean transfers and consistent color reproduction across runs, which is key for durable garment prints.

Complementary gear includes a heat press with precise temperature, time, and pressure control, plus a curing option compatible with your workflow. Garment prep supplies like Teflon sheets and alignment tools further protect fabrics and edges, supporting vibrant garment transfers and reliable results in production settings.

4) Step-by-step workflow for UV DTF transfer success

Start with design and color management, exporting high-resolution artwork and planning for underbases on dark fabrics. Print the design onto UV DTF film with UV-curable inks, then allow appropriate dwell time to maintain color fidelity before powdering.

Next, apply adhesive powder evenly and prepare the garment with a pre-press to remove moisture. Align the transfer, apply heat with the recommended settings, and complete the cure as specified by the ink and film suppliers. A careful peel and post-cure (if required) finalize the process for durable, vibrant results.

5) Troubleshooting to maintain durable and vibrant UV DTF prints

Common issues like peeling, color fading, ghosting, or edge halos can often be traced to incomplete curing, misalignment, or underbase and powder application problems. Systematically verifying each step—from printing accuracy to powder coverage—helps safeguard durability and edge quality.

Practical fixes include confirming ink compatibility with the fabric, ensuring a full cure, adjusting heat press time or temperature for the substrate, and performing test runs on sample fabrics. Regular maintenance of printers and film paths also minimizes color drift and helps keep UV DTF printing consistently vibrant.

6) Fabric-specific strategies for vibrant UV DTF results

Light fabrics typically respond well to standard white underbases and the sharpness of UV-curable inks, yielding bright and durable prints. For dark fabrics, a carefully calibrated white underbase boosts opacity and color saturation, reducing undertones and preserving detail in vibrant garment transfers.

Different materials like cotton, blends, and polyester may require tailored curing and pre-treatment steps. Testing on fabric swatches, maintaining color management with ICC profiles, and adjusting underbase thickness help ensure durable, vibrant outcomes across mixed runs and varied garment colors.

Frequently Asked Questions

What is UV DTF transfer and how does it differ from traditional DTF transfer?

UV DTF transfer uses UV-curable inks printed on a film that is later applied to fabric with a heat press. Compared to standard DTF transfer, it can deliver crisper detail and brighter color, especially on dark or bright fabrics, with strong wash-fastness when properly cured, and it often yields more vibrant UV DTF printing results.

What materials and equipment are essential for UV DTF transfer?

essential items include UV DTF film with adhesive powder, UV-curable inks and a compatible printer, a programmable heat press with accurate temperature and time controls, and a curing method (UV lamp or post-press cure). Also have garment prep supplies like Teflon sheets and proper alignment tools to ensure durable garment prints.

How can you achieve durable and vibrant UV DTF transfers on garments?

Ensure complete curing and set heat-press parameters (typically around 300–320°F / 149–160°C with appropriate pressure and time for the fabric). Use a white underbase on dark fabrics when needed, align precisely, and perform any required final cure to maximize adhesion for vibrant garment transfers and durable prints.

What are common issues with UV DTF transfer and how can you troubleshoot them?

Common issues include peeling after washes, fading colors, ghosting, cracking on stretch fabrics, and banding. Troubleshoot by verifying full cure, confirming proper underbase and powder coverage, ensuring correct alignment, adjusting heat/pressure/time for the fabric, and maintaining printer and film path cleanliness.

Is UV DTF transfer suitable for dark fabrics and how can you ensure accurate colors?

Yes, but dark fabrics usually require a white underbase to preserve brightness. Achieve accurate colors with ICC color profiles or vendor color recipes, calibrate the printer regularly, and choose inks and films compatible with UV DTF printing to obtain vibrant garment transfers.

How do you optimize UV DTF transfer for different fabrics and colors to achieve durable garment prints?

Adapt underbase weight, curing times, and adhesive settings to each fabric type (cotton, blends, polyester). Conduct color tests on scrap fabric, ensure consistent timing across runs, and tailor the film, powder, and heat-press parameters to maintain durable garment prints and vibrant results across colors.

| Aspect | Key Points | Notes/Details |

|---|---|---|

| What is UV DTF transfer |

|

|

| Why UV DTF is a strong option for durable, vibrant garments |

|

|

| Essential materials and equipment |

|

|

| Step 1: Design and color management |

|

|

| Step 2: Printing on UV DTF film |

|

|

| Step 3: Powdering and curing setup |

|

|

| Step 4: Pre-press the garment |

|

|

| Step 5: Align and press |

|

|

| Step 6: Apply heat and time |

|

|

| Step 7: Peel and cool |

|

|

| Step 8: Final cure |

|

|

| Tips for durable and vibrant results |

|

|

| Common issues and troubleshooting |

|

|

| Optimization for fabrics and colors |

|

|

| Real-world tips from practice |

|