UV DTF Printing Studio presents an exciting path for creators who want on-demand, vibrant apparel and product customization. By marrying UV printing capabilities with direct-to-film printing and the DTF printing process, you can produce durable, high-definition designs on a wide range of garments and flat goods. If you’re launching a small business or a home workshop, this guide outlines how to select equipment, plan a productive workspace, and build a scalable workflow aligned with a print-on-demand business. Understanding the DTF printing process helps ensure color accuracy, washfastness, and efficient turnarounds across different substrates. From a deliberate printing studio setup to reliable UV printing equipment, this introduction shows how the right tools and layout empower consistent, vibrant results.

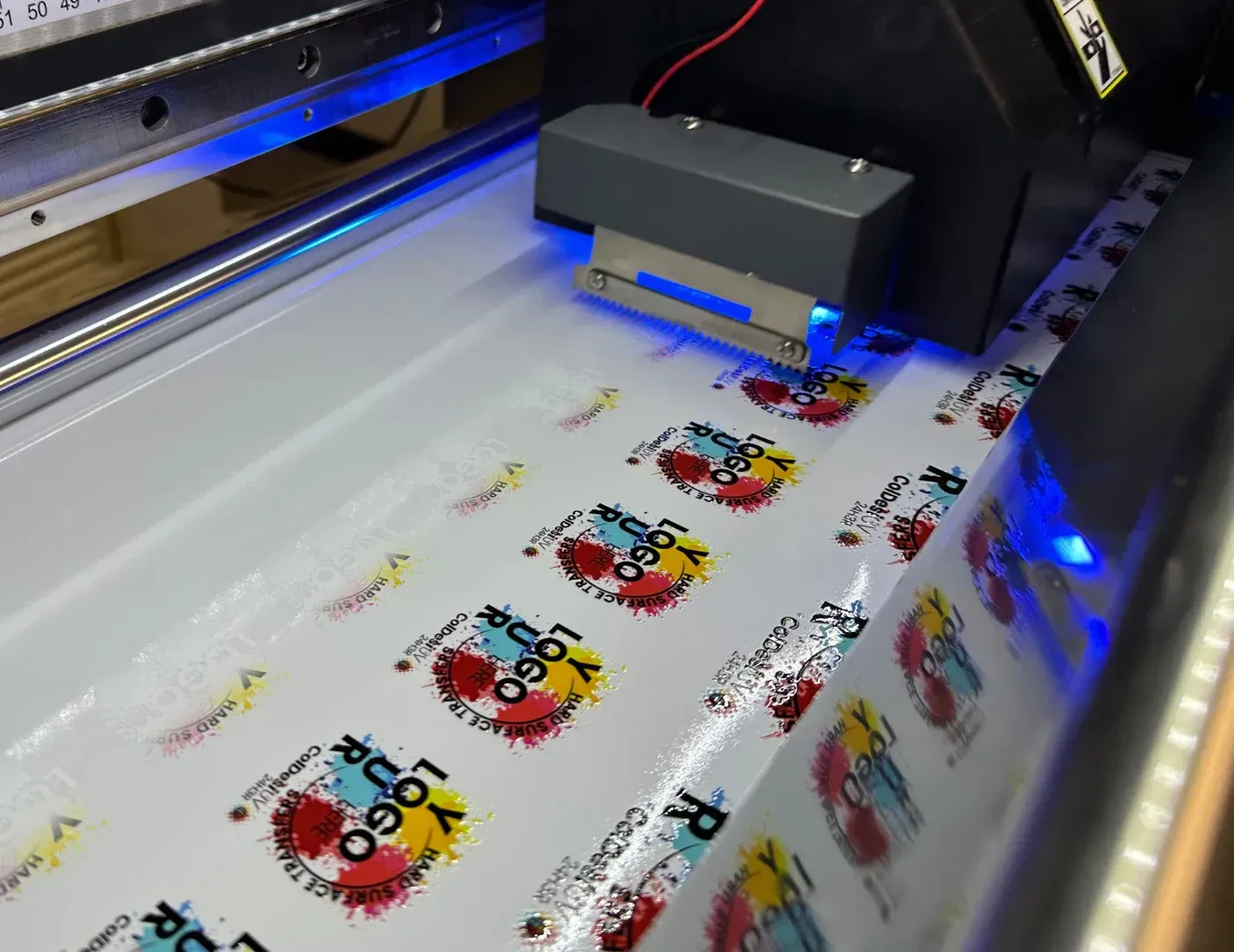

Viewed through an alternative lens, this venture resembles a digital textile printing studio that leverages UV-curable inks for vivid transfers. Think of it as a film-to-fabric transfer operation where designs are printed, dusted with adhesive powder, cured, and pressed onto garments. A contemporary apparel customization workshop emphasizes a clean, efficient layout, an organized workflow, and scalable processes tailored to on-demand orders. Effective color management, substrate compatibility, and strict quality control ensure durable results across fabrics. Labeling it as a flexible print-on-demand facility helps attract designers, teams, and brands seeking fast, personalized merchandise.

UV DTF Printing Studio: Defining Your Niche and Brand

Define your niche to tailor your UV DTF Printing Studio offerings, pricing, and marketing. Are you serving boutique fashion brands, local sports teams, or promotional events? Your concept shapes the DTF printing process you favor, the substrates you stock, and the turnaround times that customers expect, which is essential for a sustainable print-on-demand business.

Think about the value proposition—vibrant color, durable transfers, and fast turnaround—made possible by UV printing equipment and direct-to-film printing methods. By aligning your UV DTF Printing Studio with specific customer segments, you can build repeat demand, showcase your capabilities, and differentiate your studio in a crowded market.

Budgeting, Space Planning, and Equipment Essentials for a UV Studio

Budgeting and space planning are foundational steps for a successful start. Outline a realistic startup budget that covers a compact UV printer, a reliable heat press, curing equipment, and essential consumables, while leaving room for maintenance and replacement parts. A well-planned printing studio setup reduces workflow friction and supports scalable growth.

Workspace design should include dedicated storage for films, powders, and transfer sheets, plus bright, even lighting and proper ventilation. Selecting the right UV printing equipment and related tools ensures you can consistently deliver high-quality transfers, aligning with a print-on-demand business model.

DTF Printing Process Demystified: From Artwork to Transfer

Understanding the DTF printing process is central to consistent results. The typical workflow begins with printing a design onto transfer film, then applying a hot-melt powder adhesive and curing before transferring the image to the final substrate with heat.

Color management and substrate compatibility are critical for washfastness and color accuracy. As you refine the process, calibrate your printer, optimize curing times, and adapt the transfer technique to different fabrics to meet customer expectations.

Designing an Efficient Printing Studio Setup for Consistency

Designing an efficient printing studio setup reduces downtime and errors. Start with a dedicated printing area, a separate curing zone, and a cool-down/inspection station to keep throughput smooth and predictable.

Organized storage, clean work surfaces, and good lighting help minimize color shifts and improve design evaluation. A reliable ventilation plan and a safety-conscious workflow are essential for a scalable print-on-demand operation.

A Step-by-Step Production Workflow for Print-on-Demand Success

A clear step-by-step production workflow keeps orders moving from artwork to finished product. Begin with artwork preparation, ensuring design resolution, color profiles, and dimensions match the target substrate.

Then print on film with calibrated color management, apply the hot-melt powder, cure, and transfer the design using a heat press. Finishing steps like cooling, inspection, trimming, and optional post-processing ensure consistent results for a scalable print-on-demand business.

Sourcing Materials, Quality Control, and Long-Term Supplier Relationships

Materials, suppliers, and quality control form the backbone of reliable output. Source films, powders, inks, and cleaning solutions from dependable suppliers who offer consistent quality and on-time shipping.

Integrate minimal batch testing to verify color accuracy after printing, adhesive quality after curing, and successful transfers on representative fabrics. Regular supplier evaluations help maintain long-term quality for your UV DTF Printing Studio and ensure customer satisfaction.

Frequently Asked Questions

What is a UV DTF Printing Studio and why is it ideal for an on-demand customization business?

A UV DTF Printing Studio blends UV printing equipment with direct-to-film transfers to produce vibrant, durable designs on many substrates. This combination supports fast on-demand customization and broad product versatility, helping your print-on-demand business stand out. Focusing on efficient workflows and quality control enables reliable results across apparel and other items.

How does the DTF printing process work inside a UV DTF Printing Studio?

The process uses direct-to-film printing (DTF): print the design onto transfer film with UV printing equipment, apply hot-melt powder adhesive, cure the powder, and transfer the design to the substrate with a heat press. Proper color management and proper curing are essential for durability and washfastness. This workflow is central to delivering high-quality results in a print-on-demand business.

What are the essential components of a printing studio setup for UV DTF?

The core setup includes a UV printer capable of handling transfer media, a reliable heat press, and a curing station. Additional essentials are cutting tools, good ventilation, organized storage for films, powders, and transfer sheets, and strong lighting. A clean, well-organized printing studio setup reduces downtime and supports consistent output for a growing print-on-demand business.

How should I define my concept and target market for a UV DTF Printing Studio?

Define a niche such as boutique fashion brands, local sports teams, or event merchandise. This focus guides material choices, pricing, and marketing efforts, and aligns with the DTF printing process and UV printing equipment capabilities. A clear concept also strengthens SEO for UV DTF Printing Studio and related terms in your online presence.

How do I ensure quality control and manage suppliers in a UV DTF Printing Studio?

Source reliable suppliers for films, powders, inks, and cleaning solutions, and implement quality control at each step—from printing to curing to transfer. Conduct test transfers on representative fabrics and maintain batch testing to catch issues early. Strong QA supports customer satisfaction and repeat business in a UV DTF Printing Studio.

What marketing and growth strategies work for a UV DTF Printing Studio as a print-on-demand business?

Build a compelling portfolio, showcase testimonials, and create product mockups. Use an e-commerce storefront or partner with print-on-demand platforms, and optimize content with SEO keywords like UV DTF Printing Studio, UV printing equipment, and DTF printing process. Set clear pricing, realistic turnaround times, and scalable workflows to grow your print-on-demand business.

| Topic | Key Points |

|---|---|

| 1. Define your concept and target market | Outline niche before equipment; target boutique fashion brands, local sports teams, or promotional events; this focus guides material choices, pricing, and marketing; tailor the DTF printing process to customer needs. |

| 2. Budget, space, and equipment considerations | Set a realistic budget and plan a compact, organized workspace; essential gear includes a UV printer capable of transfer media, a heat press, curing equipment, and cutting tools; budget for consumables (films, powders, inks, parts); design a layout that minimizes workflow friction and supports safe, efficient operation. |

| 3. Understanding the DTF printing process | DTF printing workflow: design on film, apply hot-melt powder, cure the powder, and transfer with a heat press; focus on color accuracy, durability, and washfastness; learn curing times and best practices for various fabrics. |

| 4. Selecting and organizing your printing studio setup | Create a dedicated workspace with printing, curing, and cooling/inspection zones; separate storage for films, powders, and transfer sheets; ensure good lighting and proper ventilation; maintain a tidy, efficient workflow. |

| 5. The step-by-step production workflow | Prepare artwork (optimize for transfer, match resolution/colors to substrate); print on film; apply powder; cure; transfer with heat and pressure; perform finishing and post-processing checks. |

| 6. Materials, suppliers, and quality control | Source reliable films, powders, inks, and cleaners; build relationships with consistent suppliers; integrate quality control at each step (color after printing, adhesive after curing, test transfers); establish minimal batch testing. |

| 7. Safety, compliance, and ergonomics | Ensure proper ventilation; use PPE as needed; organize cords to reduce trip hazards; comply with local chemical handling, waste disposal, and licensing requirements; consult a business advisor if unsure. |

| 8. Marketing and business development for a print-on-demand model | Build a scalable marketing engine (portfolio, testimonials, product mockups); consider ecommerce storefronts or POD platforms; optimize SEO by integrating ‘UV DTF Printing Studio’ naturally into pages and content, along with related keywords like UV printing equipment and DTF printing process. |

| 9. Practical pricing, quotes, and turnaround expectations | Price to cover material costs, labor, and margins; create a transparent model (setup fees, per-item pricing, rush surcharges); set realistic turnaround times and clearly communicate them to customers. |

| 10. Common mistakes and how to avoid them | Avoid overinvesting; start small with core equipment; invest in a solid workflow and robust quality control; maintain a tidy, efficient space to reduce errors and increase throughput. |

| 11. Growth, expansion, and long-term planning | As orders grow, expand product lines and explore partnerships; periodically revisit DTF process and equipment capabilities; continuously refine marketing, customer service, and production to scale. |

Summary

Launching a UV DTF Printing Studio is a practical, achievable path for aspiring entrepreneurs who want high-quality, on-demand customization. By understanding the DTF printing process, selecting reliable UV printing equipment, planning a smart printing studio setup, and building a repeatable workflow, you can deliver compelling products that resonate with customers in the print-on-demand market. Stay focused on your niche, invest in quality controls, and continuously refine your processes. With dedication and smart execution, your UV DTF Printing Studio can thrive as a reliable source of personalized goods and a strong entry into the broader world of custom apparel and accessories.