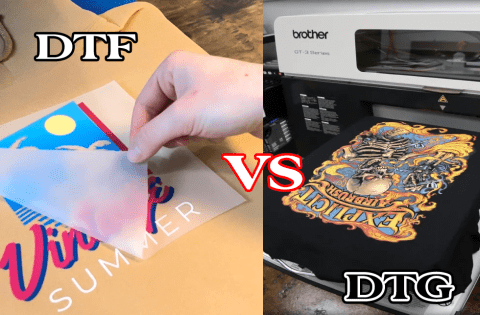

When it comes to choosing between DTF vs. DTG, understanding the differences between these two popular printing techniques is vital for any business in the custom apparel industry. Direct-to-Film (DTF) printing offers incredible versatility, allowing for prints on a wide range of fabric types, while Direct-to-Garment (DTG) printing excels in producing intricate designs with vibrant colors on cotton materials. Both methods come with their unique advantages—DTF shines in efficiency and cost-effectiveness for larger runs, whereas DTG provides exquisite detail and minimal setup costs for smaller, customized orders. Throughout this article, we’ll explore the benefits of DTF and the advantages of DTG, guiding you through a detailed print methods comparison that helps you determine which is best for your needs. Whether you prioritize quality or versatility, understanding these approaches can significantly impact your production strategy and success in the market.

In the realm of custom printing, businesses frequently debate whether to opt for Direct-to-Film (DTF) or Direct-to-Garment (DTG) methods. These two print strategies, while distinct, cater to diverse needs within the fabric printing landscape. DTF printing is sought after for its ability to adhere to various materials, positioning it as a go-to solution for businesses targeting flexible offerings. Conversely, DTG printing is prized for its capability to deliver rich colors and sharp detail directly onto fabric, particularly favored for cotton items. This discussion will encompass a detailed examination of the two techniques, highlighting the respective benefits and recent trends that define the current printing environment.

Exploring Direct-to-Garment (DTG) Printing

Direct-to-Garment (DTG) printing is revolutionizing how custom apparel is created. Utilizing inkjet technology, DTG prints directly onto fabric, which allows for sharp, intricate designs full of vibrant colors. This method is typically best suited for 100% cotton fabrics. As a result, businesses targeting niche markets or individuals seeking high-quality, unique apparel designs often gravitate towards DTG printing. The seamless process significantly reduces setup costs, making it particularly advantageous for small runs, where flexibility and detail are paramount.

Moreover, DTG offers a streamlined customization process, ideal for unique, one-off designs. Each garment can be treated as a separate entity, allowing for a variety of prints to be fulfilled in a single production run. This capability not only meets customer demands for personalized items but also allows for lower inventory levels, creating an agile and responsive business model. However, the need for cotton compatibility can limit the scope of product offerings, making DTG more suitable for specific target audiences.

Advantages of Direct-to-Film (DTF) Printing

Direct-to-Film (DTF) printing is gaining momentum due to its adaptability and cost-effectiveness. By printing designs onto a special transfer film, it allows businesses to print on a diverse array of fabrics, including cotton, polyester, and blends. This versatility caters to a broader range of products, making DTF an appealing option for businesses looking to diversify their offerings. The simplicity of the process eliminates extensive pre-treatments, thus reducing overhead costs and making it an ideal choice for larger production runs.

Additionally, DTF prints are increasingly recognized for their durability, providing longevity for various applications, from promotional items to apparel. The reduction in material waste that accompanies DTF processes further enhances its eco-friendliness, aligning with the growing demand for sustainable printing solutions. As producers seek to cater to an environmentally conscious market, embracing methods like DTF that emphasize efficiency without compromising quality becomes essential.

DTF vs. DTG: Making the Right Choice

When deliberating between Direct-to-Film (DTF) and Direct-to-Garment (DTG) printing, businesses should assess various operational factors. DTF offers cost advantages for larger print runs and a broader compatibility with materials, while DTG excels in providing meticulous detail and vibrant color representation suitable for cotton fabrics. Understanding which advantages resonate most with their business needs is critical for making an informed decision.

Moreover, the choice may also hinge on production timelines. DTF’s ability to handle batch printing efficiently often results in faster production for large orders compared to DTG. This speed is essential for businesses with fast turnaround requirements. Conversely, if the targeted market leans towards unique, personalized designs, the quality and detail offered by DTG might outweigh the rapid output provided by DTF. Businesses need to align their printing method with their unique operational goals to foster success.

Recent Innovations in Printing Technologies

The landscape of printing technologies is rapidly evolving, with novelties like the Sawgrass VersiFlex opening up new possibilities for both DTF and DTG printing methods. This technology allows for efficient printing on various surfaces with minimal pretreatment, enhancing usability for printers. The capabilities offered by innovations like VersiFlex showcase the potential to blur the lines between traditional printing methods, providing businesses with even more options for customized outputs.

Furthermore, advancements in ink formulations are constantly improving print quality and speed, promising significant enhancements for businesses that rely on fast production cycles. As these technologies continue to develop, staying updated on industry trends will be key for business owners looking to leverage the latest printing developments for competitive advantage in a dynamic market.

Cost Considerations for DTF and DTG

Understanding the cost dimensions of both DTF and DTG printing is pivotal for businesses aiming for profitability. DTF printing, particularly for larger batches, tends to be more cost-effective due to lower waste and minimal pretreatment requirements. This aspect makes it an attractive option for businesses focused on scalability and efficient resource management. As product variety expands, so does the importance of a cost-efficient printing method.

On the other hand, while DTG incurs higher expenses, particularly in setups, its quality and precision can justify the investment for businesses focusing on bespoke or high-end products. The minimal setup fees allow for smaller quantities to be produced profitably without compromising on detail. In examining cost factors, businesses must weigh their priorities—volume versus quality—to determine which method aligns best with their financial goals.

Future Trends in Custom Printing

The future of custom printing is poised for exciting growth with emerging technologies and evolving consumer preferences. As consumers increasingly seek personalized and unique products, methods that enable high-quality, efficient output like DTF and DTG will remain at the forefront. Innovations that streamline these processes will likely shape how businesses operate, allowing them to meet market demands more swiftly and effectively.

Additionally, sustainability will play a critical role in the evolution of printing practices. As businesses strive to reduce their environmental footprint, techniques that minimize waste and use eco-friendly inks will gain traction. The ongoing commitment to innovation in the printing industry will not only redefine traditional methods but also cater to an expanding clientele eager for sustainable and customizable options.

Frequently Asked Questions

What is the main difference between DTF and DTG printing methods?

The primary difference between DTF (Direct to Film) and DTG (Direct to Garment) printing lies in their application processes. DTF prints designs onto a transfer film that is then heat-pressed onto various fabric types, enabling versatility across materials. In contrast, DTG directly applies ink onto fabric, primarily cotton, excelling in producing vibrant and detailed designs. This fundamental distinction impacts factors such as material compatibility, setup costs, and overall production processes.

What are the main advantages of DTF compared to DTG printing?

DTF printing offers several advantages over DTG, including greater versatility as it can print on various fabrics, such as cotton and polyester. It is also more cost-effective for larger production runs due to reduced setup costs and the absence of extensive pretreatment. Moreover, DTF prints demonstrate durability and quality improvements, making them suitable for diverse applications beyond garments.

How does DTG printing benefit businesses focusing on intricate designs?

Businesses that prioritize intricate designs will find DTG printing to be highly beneficial. DTG utilizes advanced inkjet technology that directly applies ink onto fabric, delivering exceptional print quality with vibrant colors and fine detail. This makes DTG particularly suitable for custom orders and small runs where quality and precision are paramount, all without incurring setup fees.

Which printing method, DTF or DTG, is more cost-effective for bulk orders?

DTF printing generally proves to be more cost-effective for bulk orders. The method requires less pretreatment and fewer setup costs, making it ideal for larger production runs. In contrast, while DTG offers high-quality prints, its costs can escalate with higher volumes due to its dependence on more expensive inks and the need for pretreatment on fabrics, primarily cotton.

Can DTF printing be used on non-garment products?

Yes, one of the key benefits of DTF printing is its versatility, allowing it to be used on non-garment products as well. DTF can be applied to a variety of materials, making it suitable for items like banners, stickers, and promotional products. This adaptability opens up additional revenue streams for businesses looking to expand their product offerings beyond traditional apparel.

What should businesses consider when choosing between DTF and DTG printing methods?

When choosing between DTF and DTG printing methods, businesses should consider several factors: material compatibility, as DTF supports various fabrics while DTG is limited to cotton; production speed and efficiency, particularly for bulk orders; quality requirements for intricate designs; and overall cost efficiency based on the type of orders primarily handled (small custom runs vs. large bulk orders). Matching the printing method with market demand and product range is crucial for success.

| Feature | Direct-to-Garment (DTG) | Direct-to-Film (DTF) |

|---|---|---|

| Print Quality | Exceptional, vibrant colors, ideal for intricate designs | Improved quality and durability, versatile across media types |

| Setup Costs | No setup costs, great for small orders | More cost-effective for larger runs, less pretreatment needed |

| Material Compatibility | Best on 100% cotton and cotton blends | Works on cotton, polyester, and mixed fabrics |

| Production Speed | Slower for large batches due to individual printing | Faster turnaround for bulk orders |

| Customization | Easier for one-off designs | Versatile for multiple designs across batches |

Summary

DTF vs. DTG printing methods present unique advantages and challenges for businesses in the custom printing sector. Choosing between these methods relies heavily on individual business needs, encompassing factors such as production volume, material variety, and quality requirements. While DTG excels in print quality and is better for small batch customizations, DTF shines with its versatility and cost efficiency for larger runs. Keeping up with evolving technology and market trends is essential, as both methods advance and open new doors for innovative printing solutions. In evaluating DTF vs. DTG, ensure that your choice aligns with your business model to thrive in competitive markets.