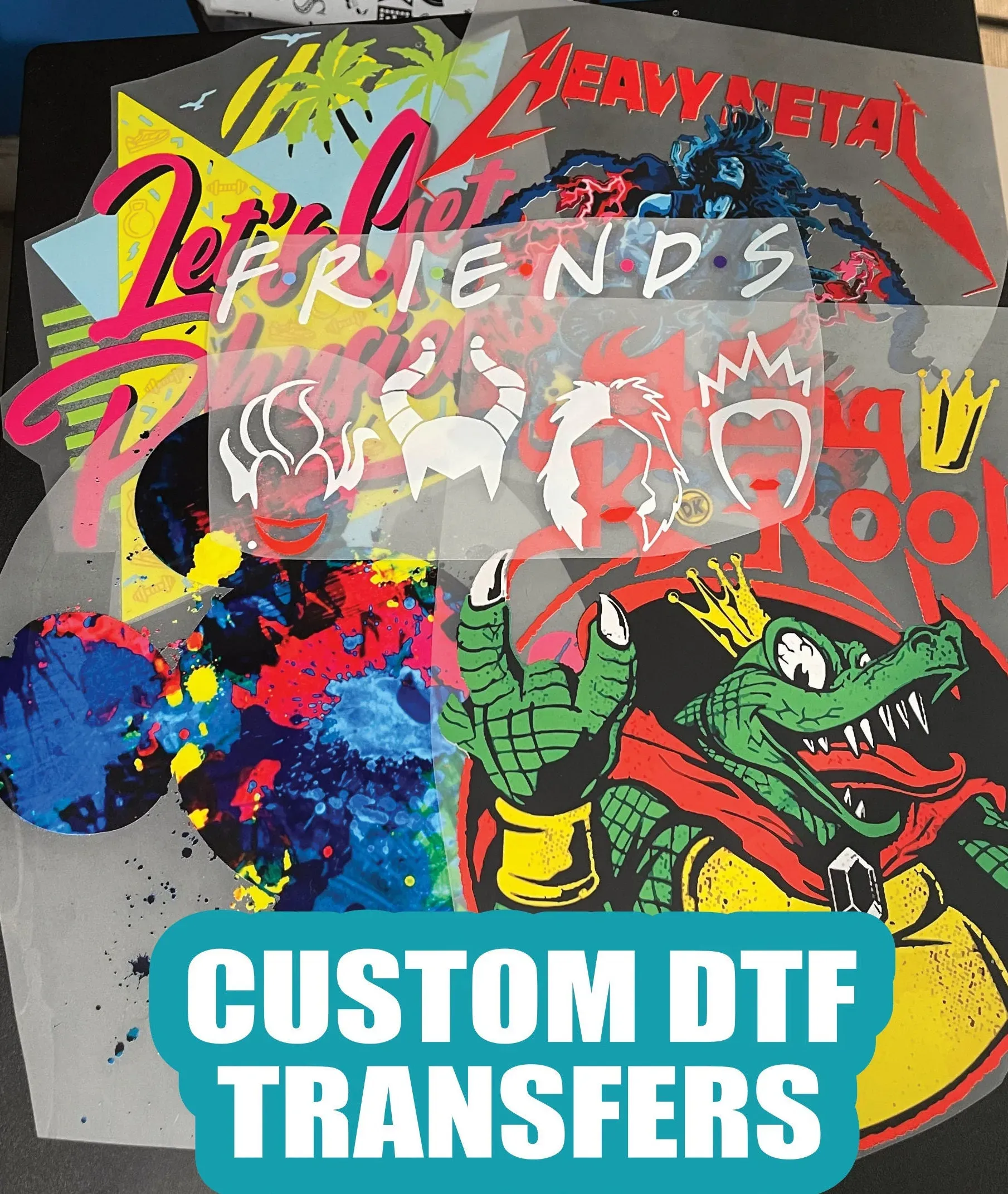

DTF transfers, or Direct to Film transfers, are propelling the evolution of the printing industry by introducing a groundbreaking method for custom apparel printing. This innovative DTF technology facilitates the production of vibrant and high-quality designs on a variety of materials, making it a game-changer for those in the printing business. As demand for personalized merchandise grows, printing companies are increasingly turning to DTF transfers to provide fast and efficient service, meeting the needs of both small businesses and large brands. The adoption of this technology not only streamlines the printing process but also enhances the creative possibilities for designers. In this article, we will delve into the remarkable advancements of DTF heat transfer products and how they are reshaping the landscape of apparel customization.

Introducing the world of DTF transfers, commonly referred to as Direct to Film printing, represents a significant shift in custom apparel production. This state-of-the-art approach allows for seamless integration of design onto fabric, eliminating the cumbersome pre-treatment steps required by older methods like Direct to Garment (DTG) printing. DTF technology stands out by offering businesses a versatile solution that can cater to various fabric types, ultimately transforming how personalized products are produced. As the printing industry evolves, innovations in DTF heat transfer products have become essential for fostering creativity and efficiency among creators and businesses alike. Join us as we explore how these printing industry innovations define the future of custom printing.

The Emergence of DTF Technology in Custom Apparel Printing

DTF (Direct to Film) technology has fundamentally altered the landscape of custom apparel printing. Traditionally, many businesses relied on methods like Direct to Garment (DTG) or screen printing, which often required significant setup and material preparation. However, DTF printing simplifies this process, allowing vibrant designs to be transferred onto various fabrics with ease. As a result, businesses can cater to a more diverse clientele by producing high-quality prints on everything from cotton t-shirts to polyester jerseys, meeting the evolving demands of the market.

Moreover, the introduction of DTF heat transfer products has opened doors for startups and small businesses that aim to enter the competitive world of custom apparel. DTF technology significantly cuts down on the costs associated with traditional printing methods, making it accessible for creators on a budget. This democratization of printing technology encourages unique design expressions and fuels the entrepreneurial spirit, empowering individual creators to thrive without facing substantial financial barriers.

How DTF Transfers Provide Quality and Versatility

One of the defining features of DTF transfers is their exceptional print quality. The prints produced through DTF technology boast vibrant colors and intricate details that not only catch the eye but also stand the test of time. The durability of these prints means they can endure washing and wear, making them ideal for everyday apparel. In contrast to conventional printing techniques that may fade or crack, DTF prints maintain their stunning appearance over numerous washes, enhancing customer satisfaction and brand loyalty.

Additionally, the versatility of DTF transfers is a game-changer for businesses looking to expand their product lines. DTF technology readily adapts to a variety of fabrics, including those that were previously challenging to print on, which further opens up creative avenues. Companies can now explore different materials, textures, and colors, allowing for a diverse range of products that resonate with customer preferences. This adaptability not only fosters innovation but also positions businesses at the forefront of market trends.

Innovations Driving DTF Heat Transfer Products

The landscape of DTF printing is continuously evolving, thanks to innovative companies introducing cutting-edge DTF heat transfer products. Businesses such as Insta Graphic Systems are pioneering advancements that enhance print quality and ease of use. By creating films that deliver sharper images and more saturated colors, these innovations are elevating the DTF printing standard and helping companies differentiate themselves in an increasingly competitive market.

Moreover, the emergence of user-friendly solutions from firms like DTFPrinter has made it easier for creators of all levels to embrace DTF technology. These advancements address common challenges faced by beginners, such as software compatibility and material selection, making the transition to DTF printing smooth and straightforward. As the barriers to entry diminish, more individuals are empowered to explore their creative potential, driving innovation in the custom printing industry.

Accessibility and Market Trends in DTF Printing

The accessibility of DTF transfers is revolutionizing the way small businesses approach custom printing. Companies like Sam’s DTF Transfers exemplify a trend towards no-minimum order policies that allow entrepreneurs to print on demand without incurring significant costs. This flexibility empowers businesses to test new designs and respond promptly to market demands, cultivating a more dynamic and competitive environment within the printing industry.

Additionally, the shift towards personalized and unique consumer products has fueled the growth of DTF printing. Customers increasingly seek apparel that reflects their individuality, and DTF technology allows businesses to fulfill this demand with rapid turnaround times. With the ability to produce customized items quickly, companies can keep up with changing consumer preferences and set themselves apart from competitors who are still relying on traditional printing methods.

Addressing Challenges in the Printing Industry with DTF Technology

While the DTF printing industry has witnessed remarkable growth, it also faces challenges that must be addressed to sustain momentum. The rapid pace of technological advancement calls for businesses to continually update equipment and training, ensuring staff are well-versed in the latest techniques. As new methods of printing emerge, companies must remain agile and adaptable to incorporate these innovations into their production processes.

Moreover, as DTF printing gains popularity, concerns regarding environmental sustainability and waste generation need to be prioritized. Many businesses are now exploring eco-friendly inks and materials to minimize their carbon footprint, contributing to a more sustainable printing industry. By addressing these challenges in a proactive manner, the DTF printing sector can continue to thrive while also maintaining a responsible approach towards the environment.

The Future of Custom Printing: DTF Transfers Leading the Way

Looking ahead, DTF transfers are poised to play a pivotal role in shaping the future of custom printing. With technological advancements making DTF more accessible, we can expect an influx of creative designs and innovative products that resonate with consumers. As fashion trends evolve and demand for personalized merchandise grows, DTF technology will be at the forefront of providing high-quality solutions tailored to meet these needs.

Additionally, as more creative entrepreneurs enter the market equipped with DTF technology, the custom printing landscape will become more diverse and vibrant. This shift not only enhances competition but also cultivates an environment where creativity thrives. Ultimately, DTF transfers are not just a passing trend; they represent a significant transformation in the printing industry, making waves that will influence market practices for years to come.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom apparel printing?

DTF transfers, or Direct to Film transfers, utilize a unique printing technology that allows designs to be printed on a specialized film. These transfers can then be heat pressed onto various fabrics, making them ideal for custom apparel printing. DTF technology enables vibrant colors and intricate details, making it a favored choice in the printing industry.

What advantages do DTF heat transfer products offer compared to traditional printing methods?

DTF heat transfer products provide several advantages, including high-quality prints with excellent durability, versatility across different fabric types (such as cotton and polyester), and lower setup costs for small runs. Unlike traditional methods, DTF allows for quick turnaround times, meeting the demands of today’s custom apparel printing market.

How has DTF technology impacted small businesses and creators in the printing industry?

DTF technology has significantly impacted small businesses and creators by lowering barriers to entry in the printing industry. It allows for affordable custom apparel printing options without hefty upfront investments. As a result, individuals and small businesses can produce unique designs, tapping into niche markets and personalizing products to meet consumer demands.

Can DTF transfers be used on various types of fabrics?

Yes, one of the key benefits of DTF transfers is their versatility. They can be applied to a range of fabrics, including cotton, polyester, and blended materials. This flexibility allows businesses in the printing industry to expand their product offerings and cater to diverse customer needs.

What innovations are driving the growth of DTF Transfers in the printing industry?

Innovations driving the growth of DTF Transfers include advancements in printing technology and user-friendly solutions that simplify the printing process. Companies like Insta Graphic Systems and DTFPrinter are introducing high-quality transfer products that enhance print vibrancy and durability, ensuring that DTF technology continues to meet and exceed market expectations.

How can businesses leverage DTF transfers to stay competitive in the printing market?

Businesses can leverage DTF transfers to stay competitive by offering personalized and high-quality custom apparel quickly and cost-effectively. By embracing DTF technology, they can respond swiftly to market trends, cater to consumer preferences for unique designs, and diversify their product lines, thus enhancing their market presence in the printing industry.

| Key Point | Details |

|---|---|

| Introduction to DTF Transfers | DTF transfers can be applied to most fabrics without extensive prep, making it flexible and appealing for businesses. |

| Key Developments | Innovative companies like Insta Graphic Systems enhance print quality, while DTFPrinter provides user-friendly solutions. |

| Benefits of DTF Transfers | Includes high-quality prints, versatility across materials, cost-effectiveness, and quick turnaround times. |

| Market Impact | DTF transfers lower barriers for entry in printing, empower creators, and help meet consumer demand for personalization. |

Summary

DTF Transfers are revolutionizing the printing industry by offering innovative, high-quality solutions tailored for modern consumers and businesses. This technology, enabling swift application on various fabric types without extensive preparatory processes, empowers creators to bring their ideas to life quickly and cost-effectively. With key advancements and the rise of accessibility, DTF transfers are solidifying their place as a transformative force in custom printing. As demand for personalized products continues to grow, DTF Transfers will undoubtedly play a pivotal role in shaping the future landscape of the printing market.