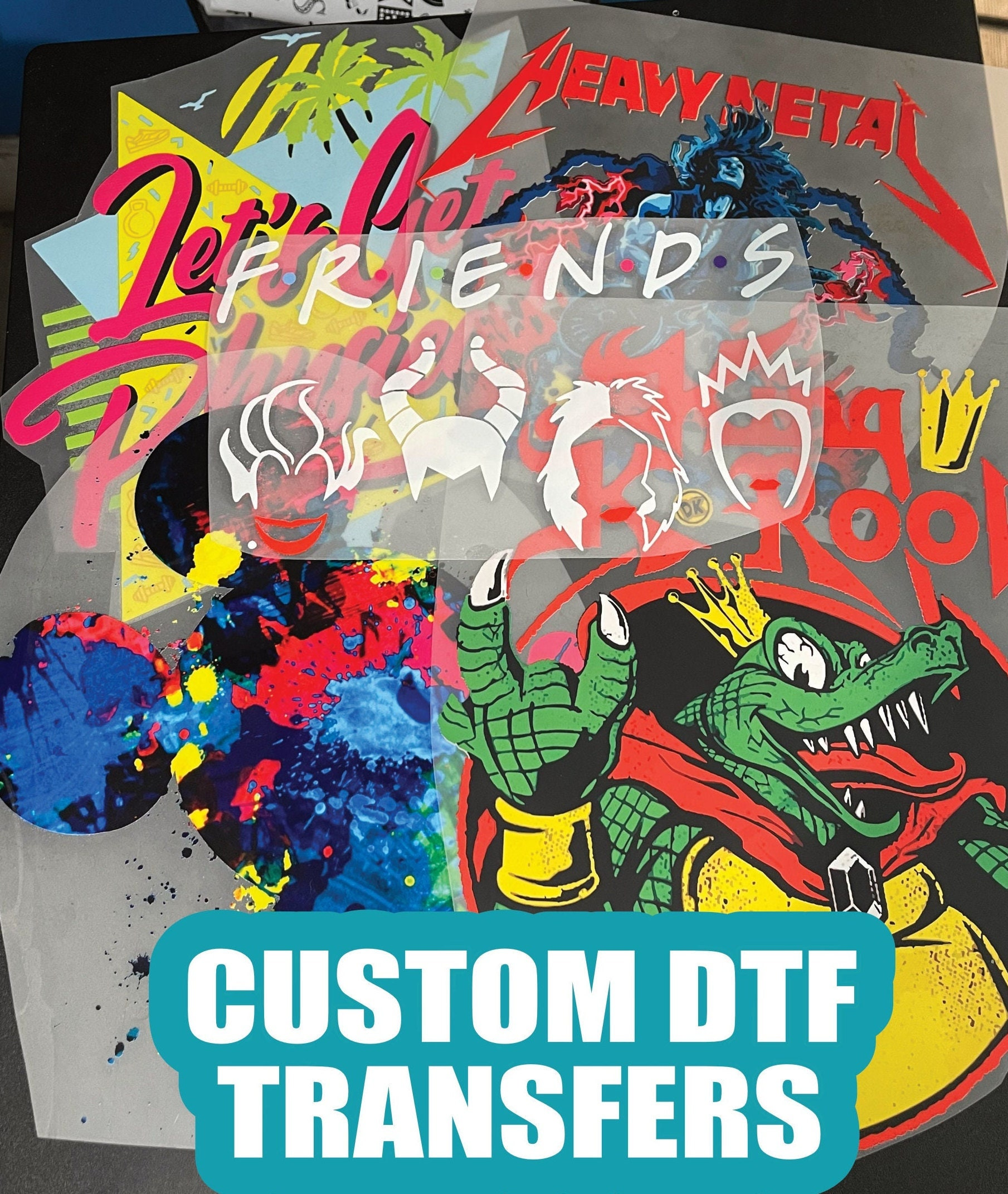

DTF transfers, or Direct to Film transfers, represent a revolutionary advancement in custom apparel printing, delivering stunning results with remarkable efficiency. This cutting-edge DTF printing process allows for the creation of high-quality prints that are not only vibrant in color but also highly durable, making them ideal for a wide array of materials such as cotton and blends. One of the key benefits of DTF transfer advantages lies in the use of gang sheets, enabling multiple designs to be printed simultaneously, which significantly reduces waste and costs. Whether you’re a small business or a creative designer, DTF transfers provide the versatility and quality needed to thrive in today’s competitive market. Join us as we delve deeper into the world of DTF transfers and uncover everything you need to know to elevate your custom apparel game.

Known in the industry as Direct to Film prints, this innovative technique has transformed how apparel is decorated, offering an efficient solution for those looking to create personalized textiles. The DTF printing method involves a streamlined process that involves printing designs onto a special film, ensuring that the final application boasts exceptional clarity and durability. With the capacity to utilize gang sheets, this method allows for economical production by printing various designs on a single sheet, making it a favorite among custom apparel creators. These high-quality prints stand out for their vibrant colors and resilience, appealing to businesses that prioritize both aesthetic appeal and long-lasting wear. As we explore the dynamics of DTF transfers, you’ll discover how this technology can open new creative horizons for your printing endeavors.

Understanding the Basics of DTF Transfers

DTF transfers, or Direct to Film transfers, represent a significant innovation in the world of custom apparel printing. This technology utilizes a four-step process that includes printing, applying an adhesive, curing, and finally transferring the design onto fabric. The impressive aspect of DTF is its ability to produce vibrant, high-quality prints that are not only visually striking but also durable. These prints are achieved through the use of specialized water-based inks that are printed onto a film, making it an ideal choice for creative entrepreneurs looking to make their mark in the textile industry.

The advantages of DTF transfers lie in their versatility and effectiveness. They can be applied to a wide variety of materials, including cotton and polyester, making them suitable for different apparel items like t-shirts, hoodies, and bags. Moreover, the process can handle multiple designs at once thanks to gang sheets, which allows for efficient production and minimized waste. This adaptability and efficiency make DTF a preferred option among businesses seeking custom apparel solutions.

The DTF Printing Process Demystified

The DTF printing process is relatively straightforward once you become familiar with each step involved. It begins with the selection of a high-quality printer specifically designed for DTF printing. The first step involves the precise printing of a design onto a specially coated film using vibrant, water-based inks. It’s crucial to ensure that the printer settings are optimized for color accuracy, as this determines the final quality of the prints.

After printing, the next step is to apply a powdered adhesive to the wet ink, which is then cured using heat. This curing process is essential as it guarantees that the powder melts and forms a stable bond with the ink, ensuring longevity and brilliance in the final product. Finally, a heat press transfers the design onto the desired garment, firmly embedding the ink within the fabric and providing an impressive finish that is resistant to fading even after numerous washes.

Exploring the Advantages of DTF Transfers

DTF transfers come with a multitude of advantages that make them highly appealing for both businesses and individual creators. One of the most notable benefits is the high quality of prints produced. Unlike other methods, DTF delivers intricate designs with exceptional color fidelity, allowing for detailed artwork that stands out on various apparel types. This high-quality output is a game changer for custom apparel printing, setting it apart from other traditional methods.

Another significant advantage is the cost-effectiveness of DTF printing. Compared to screen printing, DTF has lower setup costs and can produce designs on demand, which is especially beneficial for small businesses avoiding the need for large inventory investments. Additionally, the use of gang sheets allows businesses to print multiple designs simultaneously, enhancing productivity and reducing material waste. This efficiency, coupled with high-quality results, makes DTF transfers a smart investment for custom apparel.

Current Trends Shaping the DTF Printing Market

The landscape of DTF printing is continuously evolving, driven largely by the increased demand for personalized products. Small businesses and entrepreneurs are particularly drawn to this technology as it provides an opportunity to offer unique, custom garments without the significant investment required for larger production methods. DTF’s flexibility allows for quick adjustments, making it ideal for responding to consumer trends and preferences.

As the market for personalized apparel grows, the ability to produce high-quality prints on demand is becoming increasingly significant. Many businesses are leveraging the DTF printing process not just for t-shirts but for a wide range of products, creating a diverse portfolio. This trend indicates that as more customers seek customized options, DTF technology will continue to play a pivotal role in the custom printing space.

Best Practices for Successful DTF Transfers

To achieve the best outcomes with DTF transfers, implementing best practices is essential. One of the foremost practices involves maintaining your printing equipment. Regular cleaning and maintenance ensure that your printer continues to operate flawlessly, resulting in consistently high-quality prints. Neglecting these routines can lead to poor print quality and wasted materials, which can be detrimental to any DTF operation.

Additionally, selecting the right materials is crucial for successful DTF prints. Opting for high-quality water-based inks specifically designed for DTF can greatly enhance adhesion and color vibrancy. Another critical aspect is monitoring temperature settings meticulously during both curing and transfer, as incorrect temperatures can cause adhesion problems or damage the film itself. By adhering to these best practices, businesses can optimize their DTF printing process and ensure superior end products.

Conclusion: The Future of DTF Transfers in Custom Apparel

As DTF transfers gather momentum within the custom printing industry, their impact is undeniable. With the ability to provide stunning, high-quality prints at a lower cost, this technology is revolutionizing the way businesses approach apparel decoration. By understanding the intricacies of the DTF process and employing it effectively, creators can unlock a world of possibilities in custom apparel printing.

Looking ahead, it is clear that DTF technology will continue to advance, driven by ongoing innovations and an ever-changing market. Those involved in custom printing must stay informed about the latest trends and techniques to fully leverage the advantages of DTF transfers, ensuring they remain competitive in a dynamic industry. Whether you’re a seasoned professional or just starting out, a focus on DTF will be pivotal for future success in custom apparel.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process involves four main steps: printing the design onto a special film, applying powdered adhesive to the wet ink, curing the adhesive with heat, and finally transferring the image onto the fabric using a heat press. This method ensures vibrant and high-quality prints that are durable and long-lasting.

What are the advantages of using DTF transfers for custom apparel printing?

DTF transfers offer several advantages for custom apparel printing, including versatility across various materials, cost-efficiency with lower setup costs compared to traditional methods, and the ability to produce high-quality prints with intricate designs. Additionally, DTF prints are durable and can withstand multiple washes without fading.

How do gang sheets enhance DTF transfer efficiency?

Gang sheets in DTF transfers allow for multiple designs to be printed simultaneously on a single sheet of film. This efficient method not only reduces material waste but also saves time and costs in custom printing, making it an eco-friendly choice for businesses.

What types of fabrics can DTF transfers be applied to?

DTF transfers can be applied to a wide range of fabrics, including cotton, polyester, and various blends. This versatility makes DTF an excellent choice for custom apparel projects, enabling the decoration of t-shirts, hoodies, and bags.

Why are DTF transfers considered to provide high-quality prints?

DTF transfers are renowned for their high-quality prints due to their superior color reproduction and detail. The printing process uses specialized water-based inks that ensure vibrant colors and intricate designs that remain intact, even after multiple washes.

What are some best practices for achieving optimal results with DTF transfers?

To achieve the best results with DTF transfers, regularly maintain your printing equipment, use high-quality water-based inks specifically made for DTF printing, and accurately monitor temperature settings during both the curing and transfer processes to ensure proper adhesion and print quality.

| Key Points | Details |

|---|---|

| What Are DTF Transfers? | A printing method that uses a four-step process to transfer designs onto fabrics, producing high-quality, durable prints. |

| The DTF Printing Process | 1. Printing 2. Applying Adhesive 3. Curing 4. Heat Transfer |

| Key Benefits | – Versatile material compatibility – Cost-efficient compared to traditional methods – High-quality and durable prints – Efficient gang sheet usage |

| Current Trends | Increasing demand for personalized products and custom garments, especially among small businesses. |

| Best Practices | – Maintain equipment – Select suitable inks – Monitor temperature settings |

Summary

DTF Transfers are revolutionizing the custom apparel industry with their innovative approach to printing. This method stands out for producing vibrant, high-quality prints suitable for a wide range of materials, making it increasingly popular among businesses and creators alike. The process involves printing on a specially coated film and applying a powdered adhesive, which results in a durable bond between the ink and fabric. DTF Transfers not only enhance the quality of printed garments but also offer cost-effective solutions for on-demand printing. As trends evolve, understanding best practices in this field will help businesses maximize efficiency and production quality, paving the way for creative exploration in garment customization.