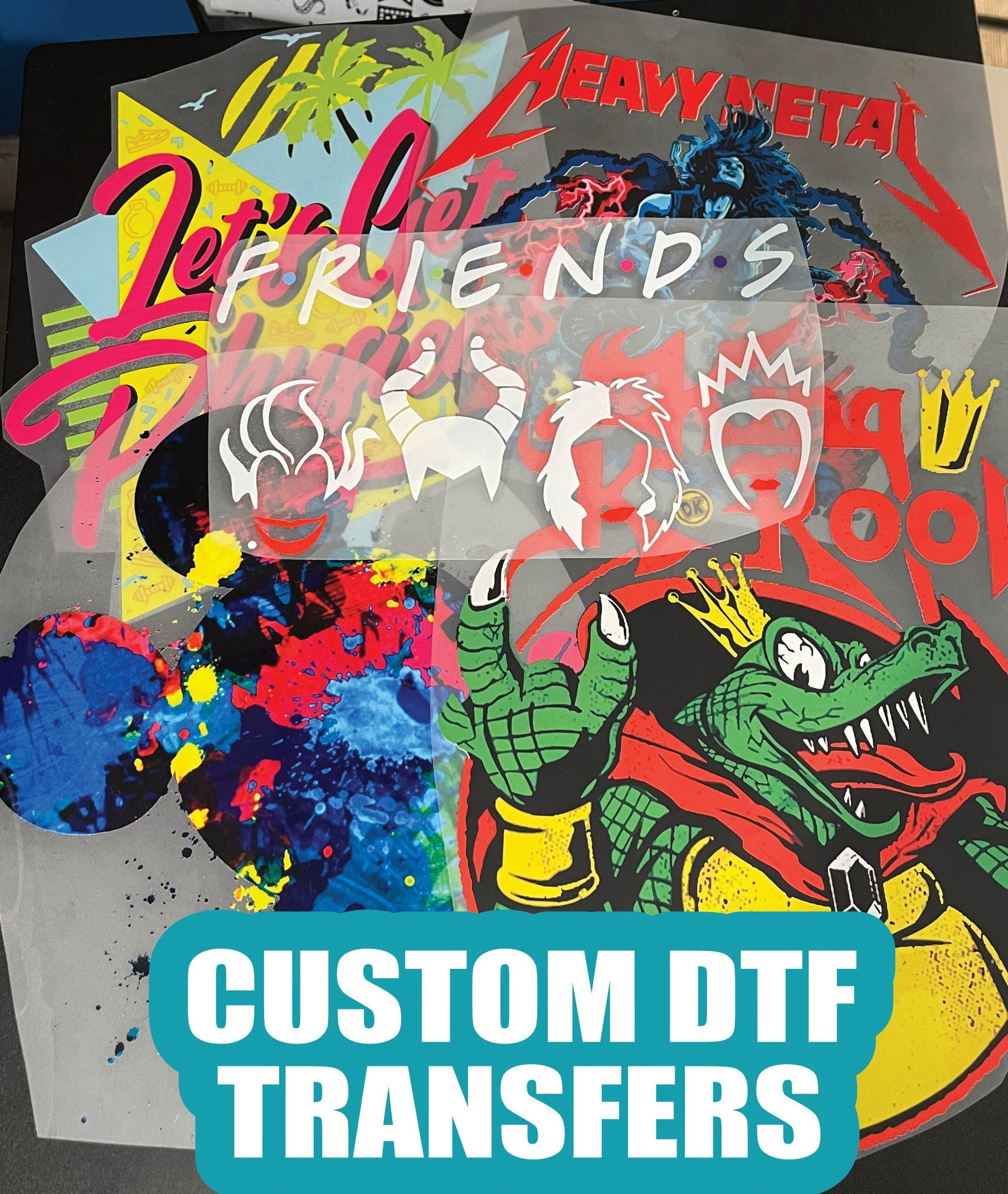

DTF transfers, or Direct-to-Film transfers, represent a groundbreaking innovation in the world of fabric printing. This versatile technique allows for the seamless application of vibrant, high-quality designs onto various fabrics, making it a favorite among both hobbyists and professionals. With the aid of DTF printing techniques, users can easily create custom apparel and accessories that withstand the test of time, even after numerous washes. To get started, a specialized DTF printer and a reliable heat press for DTF are essential, alongside other DTF printing essentials that ensure successful results. In this article, we will delve into the tools and processes involved in mastering DTF transfers, paving the way for your new fabric printing venture.

In the realm of fabric customization, there are numerous methods to achieve stunning results, yet few are as efficient and effective as Direct-to-Film printing. This contemporary printing approach, often recognized for its durability and aesthetic appeal, allows users to transfer intricate designs onto various textile materials with ease. Utilizing advanced DTF printing techniques, creators can produce high-quality prints that remain vibrant, making them ideal for custom clothing and accessories. Essential tools for this method include a specialized DTF printer and a heat press designed for DTF applications, which ensure that designs adhere perfectly to fabrics. Join us as we explore the essentials of DTF transfers and how to utilize them for your creative projects.

Understanding DTF Printing Techniques

DTF printing techniques represent a modern advancement in fabric decoration, utilizing specialized equipment to achieve vibrant results. At the heart of this process is the DTF printer, which employs high-quality inks designed specifically for transferring images onto fabrics. This differs from traditional methods like screen printing, which can limit design complexity and color vibrancy. By using DTF techniques, creators can experiment with a variety of fabrics including cotton, polyester, and blends, ensuring that their designs not only look stunning but also feel comfortable.

Moreover, the DTF printing process streamlines production, allowing for shorter turnaround times without sacrificing quality. This characteristic has made DTF transfers increasingly popular among both established businesses and start-ups. As businesses adopt DTF techniques, they benefit from improved versatility in their product offerings, equipping them to better meet consumer demands for custom apparel and unique designs.

The Essential Tools for Successful DTF Transfers

To embark on your DTF printing journey, it’s vital to gather the essential tools that will facilitate seamless execution. First and foremost, investing in a high-quality DTF printer is crucial. This printer must utilize DTF inks, which are specifically formulated to adhere to transfer films and fabrics effectively. The combination of a specialized printer and premium inks will ensure the fidelity and durability of your printed designs.

Additionally, no DTF setup is complete without a reliable heat press. This device is necessary for applying the right amount of heat and pressure to transfer designs accurately from film to fabric. Choosing the right heat press can significantly influence the efficiency of the transfer process, with features such as adjustable temperature controls and even pressure distribution being vital for successful results.

Key Considerations for Fabric Selection in DTF Transfers

Choosing the right fabric for DTF transfers is one of the most critical factors influencing the success of your prints. DTF printing works exceptionally well on materials like cotton and polyester, which are known for their ability to hold vibrant colors. However, certain blends and textures can lead to varied results; therefore, conducting test prints on unfamiliar fabrics is a wise practice.

Engaging with various fabric types can also open up creative avenues for unique product offerings. For example, mixing different fabric compositions can yield exciting new aesthetic effects. Nonetheless, it’s essential to remember that while versatility is a hallmark of DTF, some fabrics may not yield the desired results without adjustments in the printing settings or techniques.

Navigating Common Challenges in DTF Printing

Even with its many advantages, DTF printing is not without its challenges. One of the most common issues is ensuring proper adhesion of the transfer to the fabric, which can be influenced by factors such as heat and pressure settings. If the transfer lifts during washing, it can impact the overall quality and lifeline of the print. Therefore, understanding the right parameters for your specific materials is crucial to navigate these pitfalls.

Another challenge arises during the removal of DTF transfers. While these transfers are designed to last, mishandling during the removal process can damage the underlying fabric. Users should be equipped with knowledge about using heat judiciously for safe transfer removal, as excessive heat can lead to unwanted fabric damage. Seeking advice from seasoned DTF users or professional practitioners can provide valuable insights and techniques to mitigate these issues.

Exploring Recent Developments in the DTF Industry

The DTF industry has witnessed exciting developments in recent months, enhancing the accessibility and efficiency of this printing method. Innovations such as the new trade services introduced by companies like Snuggle mean that small businesses can now easily access high-quality DTF transfers without investing heavily in equipment. This democratization of technology supports more entrepreneurs in exploring fabric printing as a viable business opportunity.

Additionally, capacity expansions by leading firms such as EazyDTF indicate a growing recognition of the DTF printing method’s potential. By investing in new equipment and increasing production capabilities, these companies are responding to rising demand from the market, ensuring that customers receive timely and quality services. Keeping abreast of such industry advancements can provide valuable insights for anyone looking to establish or scale up their DTF printing operations.

Best Practices for Maximizing Quality in DTF Transfers

To achieve the best possible results with DTF transfers, it’s essential to adhere to established best practices throughout the printing process. Start by ensuring your DTF printer is calibrated correctly and that the design files are prepared suitably for the medium. Accurate color profiles and resolution settings can significantly enhance the final print quality, preventing issues such as misalignment or color bleed.

Maintaining a clean workspace and regularly maintaining your equipment can further mitigate issues that may arise during printing. Pay close attention to the quality of your transfer films and inks; using subpar materials may lead to disappointing results. By taking these precautions and continually educating yourself about DTF printing essentials, you can maximize the durability and appeal of your final products.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a modern printing technique that allows for high-quality designs to be printed onto various fabrics. This method involves printing designs on a special film using a DTF printer and then transferring those designs onto fabric using a heat press. The inks used in DTF printing are specifically formulated to adhere well to fabrics, producing vibrant and durable results.

What essential equipment do I need for DTF printing?

To get started with DTF printing, you will need a few essential tools: a specialized DTF printer for printing on transfer film, a high-quality heat press for transferring designs onto fabrics, DTF transfer film and inks that are compatible with your printer, and design software that helps you create and manage your print files effectively.

Can I use any fabric with DTF transfers?

Yes, DTF transfers work well on a variety of fabrics, including cotton, polyester, and fabric blends. However, the final print quality may vary depending on the type of fabric used. It’s advisable to conduct test prints on different materials to ensure optimal results.

What are the advantages of using DTF printing techniques?

DTF printing techniques offer several advantages, including versatility in application across multiple fabric types, vibrant color output, and excellent durability that holds up well after multiple washes. This makes DTF transfers an appealing choice for custom apparel and accessories.

How do I ensure proper adhesion when using a heat press for DTF?

To ensure proper adhesion with a heat press for DTF transfers, set the appropriate temperature and pressure as specified by your DTF printer and transfer film instructions. Additionally, pre-heat your fabric to remove moisture and ensure the design bonds effectively without damaging the material.

What common challenges should I consider with DTF printing?

Common challenges with DTF printing include ensuring accurate alignment of the transfer, managing heat settings correctly to avoid fabric damage, and maintaining the quality of printed transfers. Regular quality checks, testing on different fabrics, and seeking advice from experienced users can help mitigate these challenges.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | DTF transfers use a special film printed with inks to transfer designs directly onto fabrics, offering vibrant colors and durability. |

| Recent Industry Developments | 1. Snuggle launched a new trade service for DTF transfers, enhancing accessibility for businesses. 2. EazyDTF expanded their capacity with ten new printers for same-day shipping. |

| Essential Tools for DTF Transfers | – DTF Printer – Heat Press – DTF Transfer Film and Inks – Design Software |

| Practical Considerations | – Follow correct process – Choose appropriate fabrics – Monitor quality control |

| Common Challenges and Solutions | – Use heat carefully for transfer removal – Seek advice from professionals or experienced users |

Summary

DTF transfers represent a transformative approach to fabric printing, enabling creators to produce high-quality designs with ease. This method not only provides vibrant and long-lasting results but also addresses the modern demands of both small businesses and hobbyists. By utilizing specialized equipment and adhering to best practices, anyone can efficiently explore the creative possibilities of DTF transfers, making them a preferred choice in the textile industry.