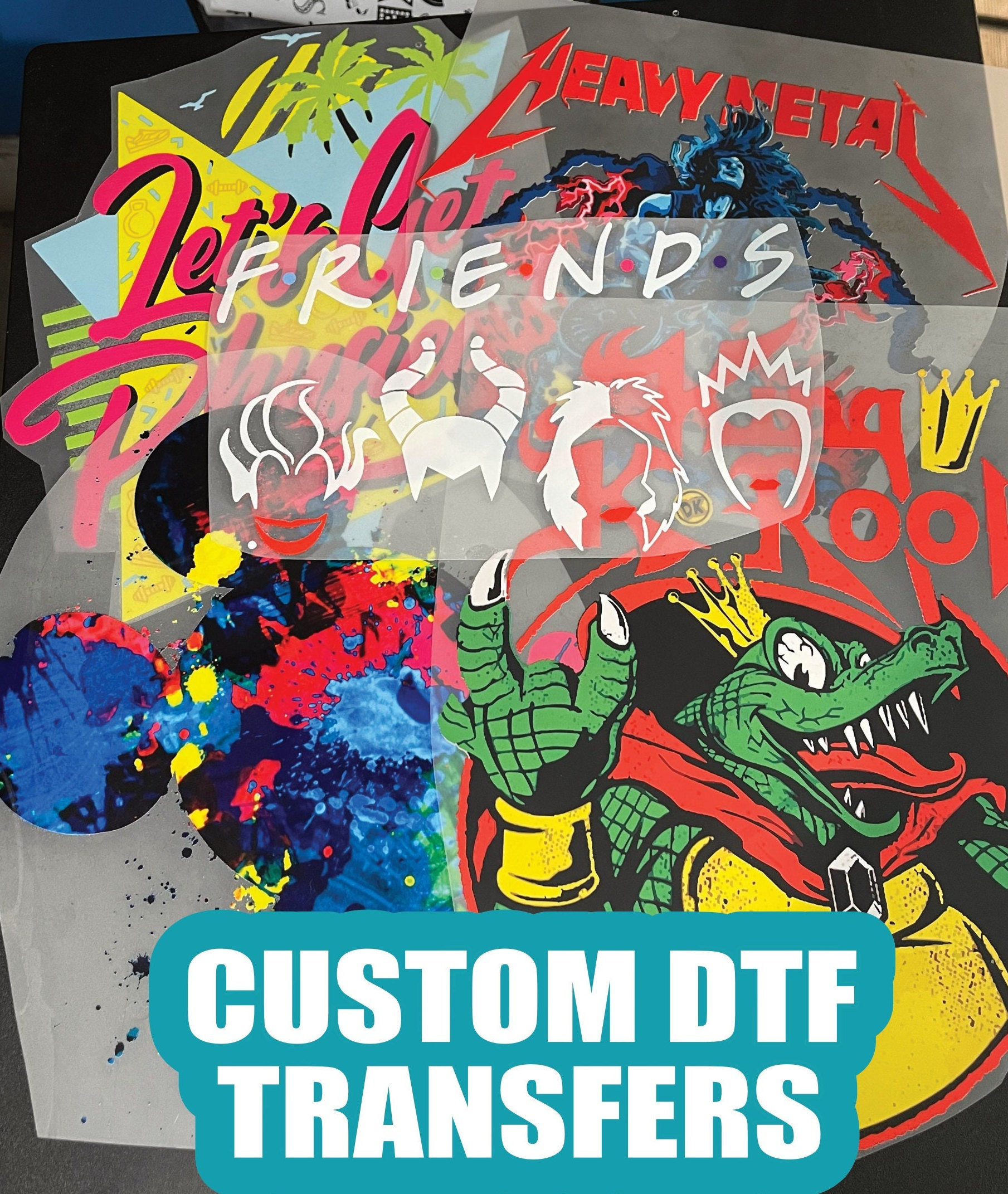

DTF transfers, short for Direct-to-Film transfers, represent a groundbreaking advancement in garment printing technology, offering remarkable versatility and quality. Despite their rising popularity, numerous myths about this innovative printing method can lead to confusion among garment decorators and DIY enthusiasts alike. In this article, we will unravel some of these misconceptions surrounding DTF printing, emphasizing its unique benefits and applications within the industry. Whether you’re comparing DTF vs DTG (Direct-to-Garment) methods or exploring the various DTF printing benefits, our guide will provide you with essential insights to help you make informed decisions. Join us as we dive into the world of DTF transfers and discover how they can elevate your custom apparel printing projects.

In the realm of contemporary printing solutions, the term Direct-to-Film transfers refers to a method that bridges digital printing with traditional techniques, offering exceptional results for custom fabric applications. This approach, often juxtaposed with methods like Direct-to-Garment (DTG) printing, utilizes a specialized film to deliver vibrant designs onto various materials. As we explore the many advantages associated with DTF printing, including longevity and cost-effectiveness, it becomes clear that this technology is reshaping textile production. Understanding the nuances of this garment printing technology can empower printing professionals and hobbyists alike to choose the best option for their creative endeavors.

Debunking DTF Printing Myths

The world of DTF (Direct-to-Film) printing is rife with myths that can mislead enthusiasts and professionals alike. One of the most prominent misunderstandings is that DTF transfers compromise on durability. Contrary to popular belief, DTF prints can endure multiple washes while retaining their original quality. Unlike some other printing methods that may fade or peel quickly, the adhesive used in DTF transfers ensures that the design remains intact and vibrant long after application.

Another common myth is the stigma around the type of fabrics DTF can be applied to. Many believe that DTF is limited to lighter fabrics, but advancements in technology have proven otherwise. DTF transfers can now be effectively utilized on various fabric colors and textures, including dark materials. This versatility opens up new possibilities for custom apparel designs that appeal to a broad audience.

The Advantages of DTF Transfers

When comparing DTF transfers to other garment printing technologies, the benefits of DTF become apparent. For starters, DTF printing is incredibly cost-effective, particularly for smaller batch orders. Traditional screen printing often involves high setup costs, making it less ideal for small businesses or hobbyists looking to create custom pieces. In contrast, DTF allows for affordable production without sacrificing quality, making it a popular choice for those new to custom apparel creation.

In addition to being budget-friendly, DTF prints are known for their striking color vibrancy and detail. The advanced inks used in DTF printing technology result in eye-catching graphics that maintain their brilliance, wash after wash. This capability stands out especially when compared to other methods like Direct-to-Garment (DTG), which can struggle to achieve the same level of detail in certain designs due to fabric compatibility.

Comparing DTF and DTG Printing

When evaluating printing options, many individuals find themselves torn between DTF and DTG printing. While both technologies utilize digital methods to produce designs, they operate differently at a fundamental level. DTG printing applies ink directly onto the fabric, which can be limiting in terms of materials and colors. In contrast, DTF transfers first print designs onto a special film before transferring them onto the fabric, allowing for greater versatility in production.

The distinction between DTF and DTG is crucial for those in the garment industry. DTF printing supports a wider range of fabrics and colors, particularly on dark garments, thus broadening the design spectrum. Moreover, the transfer process of DTF printing can often produce more intricate designs compared to DTG, which is limited by direct fabric application. Understanding these differences can aid producers in selecting the most appropriate printing method for their specific needs.

Educational Resources for DTF Printing

Many beginners express concern about the complexities of DTF printing, thinking it requires extensive technical expertise. However, a wealth of educational resources has emerged to support those new to the craft. Online tutorials, video guides, and community forums provide insights into the DTF process, demystifying the learning curve that often intimidates newcomers. With a bit of dedication and the right resources, anyone can master the DTF printing technique.

Furthermore, these educational platforms not only highlight the printing process but also share best practices for troubleshooting common issues that may arise. As the DTF printing community grows, the availability of knowledgeable support becomes vital in helping both novices and seasoned printers refine their skills. By tapping into these resources, individuals can significantly enhance their understanding of DTF technology without the fear of making mistakes.

The Eco-Friendly Edge of DTF Printing

In today’s environmentally conscious market, the printing methods businesses choose play a crucial role in their sustainability practices. DTF printing offers an eco-friendly advantage due to its reliance on water-based inks, which significantly reduce the use of harmful chemicals traditionally employed in textile printing. This shift towards more sustainable practices can attract environmentally aware consumers and reinforce a brand’s commitment to eco-friendliness.

Additionally, as brands promote sustainability, the eco-conscious appeal of DTF printing could lead to increased demand and greater market relevance. With a growing audience looking for responsible sourcing and production practices, incorporating DTF technology into a business model can not only enhance a brand’s reputation but also contribute positively to environmental conservation efforts.

Recent Innovations in DTF Technology

As the field of DTF printing rapidly evolves, recent innovations are propelling the technology further into the forefront of garment printing. New advancements in ink formulations have improved color fidelity and wash durability, making DTF an increasingly attractive option for businesses. Innovations are also focusing on improving the ease of use of DTF equipment, allowing even those with minimal experience to engage with this printing method effectively.

These developments indicate a promising future for DTF transfers, providing a broader range of applications across various industries. The continuous refinement of printing technology ensures that DTF remains a viable option for both hobbyists and professionals alike, offering them the tools to capitalize on market trends and consumer demands for personalized and high-quality prints.

Frequently Asked Questions

What are the main benefits of DTF transfers in garment printing technology?

DTF transfers, or Direct-to-Film transfers, offer several benefits in garment printing technology, including cost-effectiveness, vibrant colors, and excellent durability. This printing method allows for intricate designs that maintain their quality through numerous washes, making DTF a preferred choice for both hobbyists and professionals looking for high-quality results.

How do DTF transfers compare to DTG printing?

DTF transfers are different from DTG (Direct-to-Garment) printing in their application process. While DTG directly prints ink onto the fabric, DTF printing involves printing designs onto a special film that is then transferred to the garment. This fundamental difference allows DTF to work effectively on various fabric types, including dark colors, expanding its usability compared to DTG.

Are DTF transfers only suitable for light-colored fabrics?

A common myth is that DTF transfers are only suitable for light-colored fabrics. In reality, DTF technology has been designed to work effectively on a wide range of fabric colors, including dark garments. The transfer film used in DTF printing adheres well to different materials, making it versatile for customizing apparel of all colors.

What are some common myths about DTF printing durability?

One of the main myths regarding DTF printing is that it lacks durability. However, DTF transfers are known for their resilience, maintaining quality after multiple washes without fading or peeling. When applied correctly, they provide long-lasting prints, making them ideal for the garment industry.

Is the DTF printing process complicated for beginners?

Many believe that the DTF printing process is complicated, which can discourage beginners. However, there are numerous resources and tutorials available that make it accessible and straightforward. Many users have successfully adopted DTF printing with ease due to the support and educational materials available.

How do DTF transfers contribute to eco-friendly garment printing?

DTF transfers can be considered eco-friendly because many DTF inks are water-based and use fewer harmful chemicals compared to traditional printing methods. This makes DTF a more sustainable option for brands and consumers who prioritize environmental responsibility in their garment printing choices.

| Common Myths About DTF Transfers | Myth | Fact | |

|---|---|---|---|

| DTF Transfers are Not Durable | DTF prints are resilient, withstand multiple washes without fading or peeling. | ||

| DTF is Only Suitable for Light Fabrics | DTF technology works effectively on dark garments and various fabric types. | ||

| DTF is the Same as DTG Printing | DTF prints on a film first, then transfers to fabric, unlike DTG which applies ink directly onto fabric. | ||

| The DTF Process is Complicated | Numerous resources and tutorials simplify DTF printing for beginners. | ||

Summary

DTF transfers have emerged as a game-changer in the world of textile printing, offering an innovative and effective solution for custom apparel. By breaking down common myths surrounding DTF technology, individuals can appreciate its durability, versatility across fabric types, and the straightforward nature of the process. As advancements continue to shape this technology, its cost-effectiveness and eco-friendly attributes make it a top choice for aspiring designers and businesses alike. With the right understanding, DTF transfers can significantly enhance the creativity and quality of printed garments, setting a new standard in the printing industry.