DTF Transfers, or Direct to Film transfers, have revolutionized the world of fabric printing techniques, offering creators a chance to produce vibrant designs with remarkable ease. This innovative method combines digital printing and heat transfer printing to achieve stunning results on a variety of fabrics. In today’s guide, we will delve into a DTF printing tutorial that reveals essential steps for crafting breathtaking designs that can elevate any apparel. Whether you’re just starting or looking to refine your skills, mastering DTF transfers can be a game-changer for your design projects. Prepare to unlock your creative potential and create stunning designs that catch the eye!

Direct to Film printing, often abbreviated as DTF, is becoming a popular choice in the realm of heat transfer technologies, allowing users to transfer intricate designs directly onto fabric. This method stands out among fabric printing techniques due to its versatility and ability to execute detailed graphics vividly. By utilizing specialized transfer films and water-based inks, artists and entrepreneurs can embark on a journey to create stunning apparel that reflects their unique vision. Different from traditional printing options, DTF offers a seamless process that is both efficient and cost-effective for a variety of material types. Join us as we explore the innovative methods and tips that will enable you to master the art of DTF printing.

Understanding the Basics of DTF Transfers

In the realm of fabric printing techniques, Direct to Film (DTF) transfers have emerged as a groundbreaking method for creating visually striking designs. DTF transfers utilize a unique process where a design is printed onto a special film, making it versatile for various fabric types, including cotton and polyester. This technique distinguishes itself from traditional heat transfer printing by using a specialized adhesive powder that ensures a robust bond between the print and fabric, resulting in high-quality outputs that retain vibrancy and durability over time.

Moreover, mastering the basics of DTF printing can elevate your design skills significantly. It involves key stages, including graphic design creation and meticulous printing methods. Starting with the design phase is crucial, as the right software selection, like Adobe Illustrator, ensures that your designs are both scalable and print-ready. Understanding how DTF’s high-resolution printing capabilities translate into stunning visuals on fabric can be the difference between an average product and a standout piece.

Step-by-Step Process for DTF Transfers

Creating stunning designs with DTF transfers involves a series of organized steps tailored to optimize the final output. Firstly, employing graphic design software effectively allows you to brainstorm and refine your design, ensuring that it aligns with your creative vision. After crafting a high-resolution image, the next step features the utilization of a DTF printer, which is specifically designed to handle the intricacies of printing on special DTF film. This stage is critical, as it sets the foundation for the quality of the transfer that will ultimately be applied to fabric.

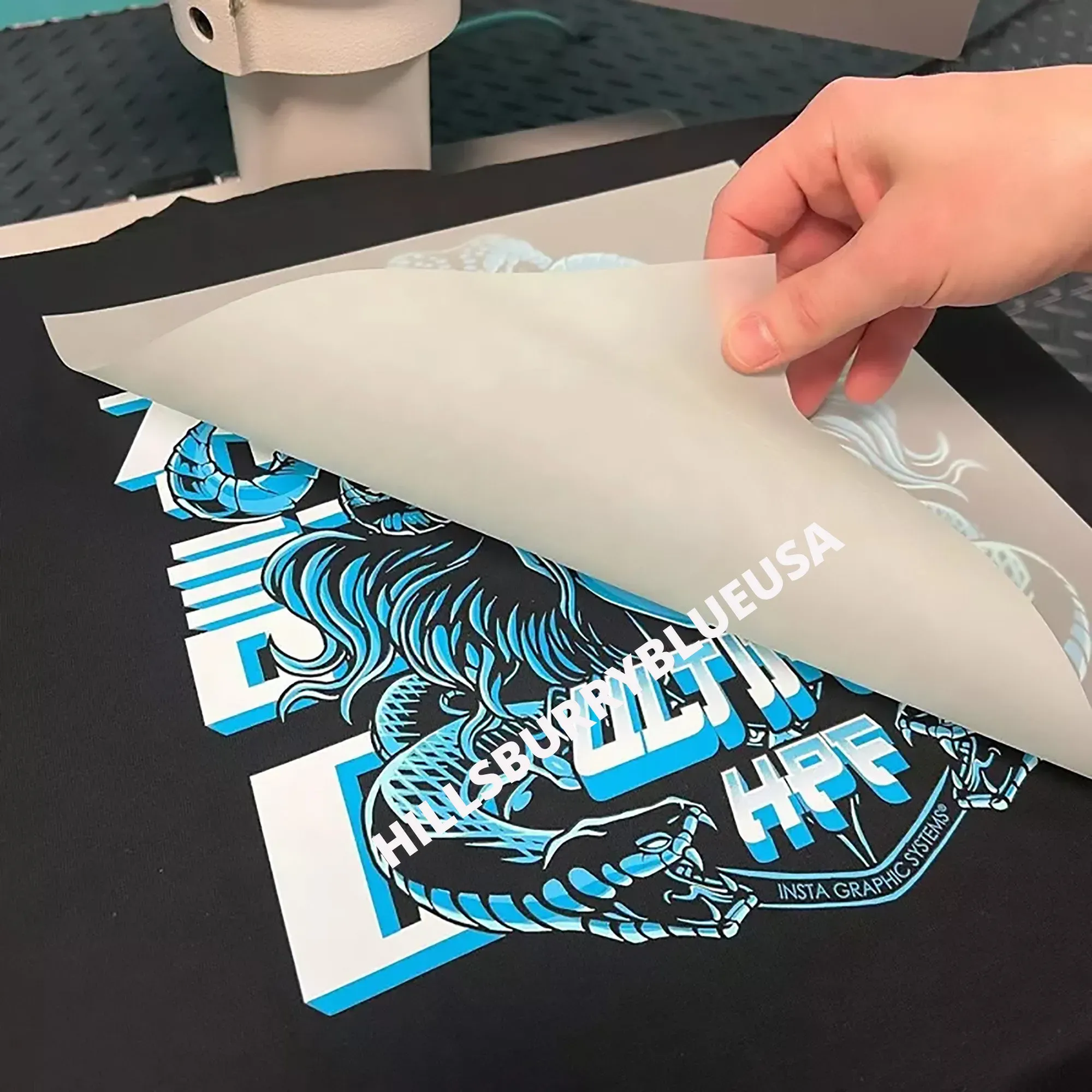

Following the development of your design, the process continues with the application of adhesive powder while the ink is still wet. This technique enhances the adhesive properties of the transfer during heat application. Once the adhesives are set, preheating the fabric ensures that moisture is eliminated, which helps in achieving a successful and long-lasting transfer. Each step in this comprehensive process contributes significantly to the final aesthetic and durability of your designs.

Essential Equipment for DTF Printing

For successful DTF printing, having the right equipment is paramount. Invest in a reliable DTF printer that utilizes water-based inks—this ensures that the prints are vibrant and adhere well to the fabric. The printer plays a critical role in the quality of your designs; hence, researching reputable brands and models designed for fabric printing techniques becomes essential. Additionally, a high-quality heat press is vital for applying the transfer accurately, offering precise temperature control and consistent pressure to achieve professional results.

Moreover, you will need a selection of transfer films and adhesive powders compatible with your DTF printer. These materials are engineered specifically for the DTF printing technique, ensuring that the final product is both visually appealing and durable. Having the right tools not only simplifies the process but also empowers you to experiment effectively, leading to exciting and unique fabric printing creations that reflect your style.

Tips for Success Using DTF Transfers

Achieving excellence in DTF transfers requires more than just following steps; it involves strategic approaches to ensure optimal results. Selecting the right materials is foundational; DTF technology works exceptionally well on cotton, polyester, and blends. It’s advisable to conduct a compatibility test with your fabric choice, as certain materials enhance color vibrancy and transfer longevity. Furthermore, understanding the dynamics of your DTF printer helps to optimize ink settings for different fabric types, ensuring that the printing process yields the best possible effects.

Additionally, leveraging color management tools available in various design software can dramatically improve print accuracy. As colors may appear differently in digital formats, utilizing tools that simulate print outputs can help refine your designs before actual printing. Finally, don’t hesitate to experiment with heat settings and timings; finding the perfect balance is sometimes a process of trial and error, but can lead to more impactful designs that truly stand out in the market.

Exploring Recent Developments in DTF Technology

The landscape of DTF printing continues to advance, providing creators and entrepreneurs with evolving tools and resources to enhance their craft. Recent developments include improved DTF printers offering greater speed and efficiency, enabling users to handle larger volumes with ease. These technological upgrades also feature more streamlined processes for applying adhesives, resulting in fewer misprints and wasted materials. Keeping abreast of these advancements can significantly impact productivity and the overall quality of your prints.

Additionally, the rise of online workshops and tutorials for DTF printing has made this technique more accessible than ever. Platforms like YouTube host a plethora of videos that guide users through the process, catering to various skill levels from novice to expert. Participating in online forums and community groups focused on DTF can foster collaboration among users, sharing insights and troubleshooting tips that can enhance your DTF printing experience.

Resources for Mastering DTF Transfers

To truly excel in DTF transfers, taking advantage of available resources can make a significant difference. Websites such as Printful offer detailed blogs and guides covering every aspect of the DTF printing process. These resources include tutorials, design tips, and insights into the latest industry trends, making them invaluable for both beginners and seasoned professionals. Further, accessing comprehensive guides can demystify complex processes and empower you to create unique designs confidently.

In addition to online articles, communities and forums provide platforms for learning and sharing experiences. Engaging with fellow DTF users helps to cultivate a sense of camaraderie; you can exchange valuable tips and troubleshoot common issues together. Participating in live Q&A sessions or webinars conducted by industry professionals can also enhance your understanding of DTF technology, staying up-to-date with the latest materials and methods that keep the craft fresh and exciting.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct to Film Transfers, are a fabric printing technique where vibrant designs are printed onto a special transfer film and then applied to fabric using heat. This innovative method enables detailed and colorful graphics to be transferred onto a variety of materials, including cotton and polyester.

What materials are best for DTF Transfers?

DTF Transfers work exceptionally well on cotton, polyester, and poly-blend fabrics. These materials have the right composition to ensure the heat transfer prints adhere effectively, offering vibrant colors and durability compared to other fabric printing techniques.

How can I create stunning designs using DTF Transfers?

To create stunning designs with DTF Transfers, start by designing your graphic using software like Adobe Illustrator or CorelDRAW. Ensure your images are high resolution (300 DPI) for clarity, then print them using a DTF printer and apply them to the prepped fabric with a heat press for durable results.

What settings do I need for heat transfer printing with DTF?

For heat transfer printing with DTF, set your heat press to approximately 320°F (160°C) and apply firm pressure for about 15-30 seconds. Adjust settings based on the fabric type and printer specifications to achieve the best results.

Where can I find a DTF printing tutorial for beginners?

You can find a DTF printing tutorial for beginners on platforms like YouTube, where numerous channels provide step-by-step guidance. Additionally, blogs such as Printful’s blog cover essential tips and techniques for mastering DTF Transfers.

What advantages do DTF Transfers have over traditional printing methods?

DTF Transfers offer several advantages over traditional printing methods, including versatility on different fabric types, the ability to print detailed and high-quality images, and reduced setup times. This makes DTF an appealing choice for both hobbyists and small businesses looking to create professional-quality printed apparel.

| Key Step | Description |

|---|---|

| 1. Design Creation | Utilize graphic design software and ensure high resolution for your images. |

| 2. Printing the Transfer | Print on DTF film using a DTF printer and apply adhesive while ink is wet. |

| 3. Prepping the Fabric | Preheat the fabric to remove moisture and facilitate transfer adherence. |

| 4. Applying the Transfer | Position the transfer carefully and press with heat at the right settings. |

| 5. Final Touches | Remove the film while warm and press again for durability. |

Summary

DTF Transfers are a remarkable method that unlocks the potential of vibrant design on fabrics with relative ease. This innovative technique allows designers to transfer their artwork onto various textiles, facilitating creativity whether for personal projects or commercial ventures. By mastering the steps of design creation, printing, prepping fabric, applying transfers, and finalizing the product, creators can achieve stunning results. As DTF technology continues to advance, resources and support for learners are becoming more abundant, enabling more individuals to explore the exciting world of DTF Transfers.