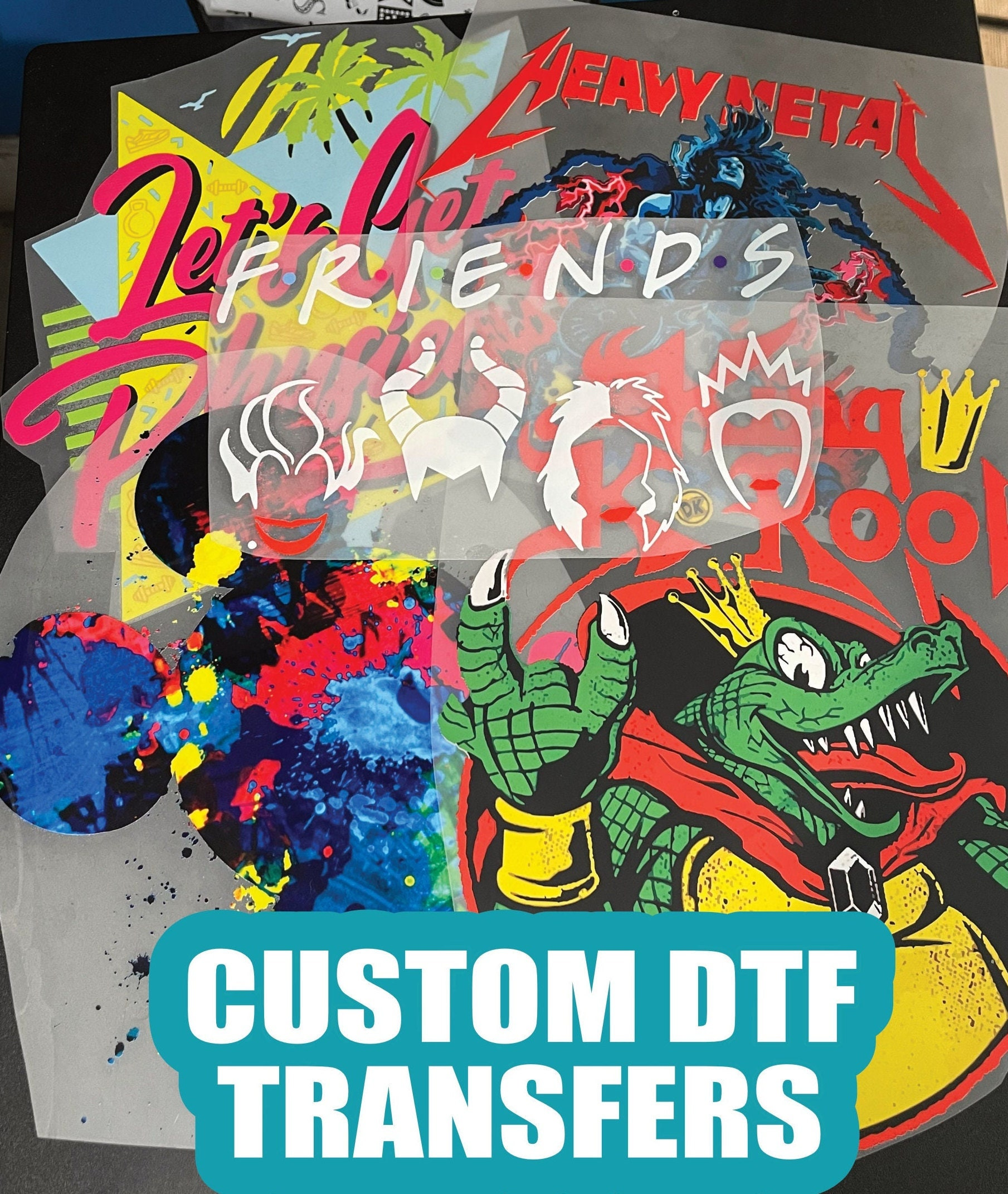

DTF Transfers have revolutionized the landscape of garment printing technologies by providing an innovative approach to custom apparel production. Direct-to-Film printing allows for detailed and vibrant designs to be applied to a variety of fabrics, making it a game-changer in the world of textile printing innovation. This technique enhances the capabilities of traditional methods such as screen printing and Direct-to-Garment printing, combining their best features while overcoming common limitations. As we delve into the DTF printing process, you’ll discover how it not only streamlines production but also meets the growing demand for personalized apparel. Explore how DTF Transfers can elevate your business and satisfy consumer craving for unique fashion.

Often referred to as Direct-to-Film technology, this method embodies a cutting-edge solution for textile decorators looking to produce high-quality custom garments. By utilizing advanced printing processes, this innovative approach enhances the efficiency and versatility of traditional garment printing techniques. With its ability to seamlessly transfer vibrant designs onto various fabric types, this printing method is quickly becoming the preferred choice in custom apparel production. The evolution of this technology represents a significant advancement in textile printing innovation, poised to meet the ever-evolving needs of modern consumers. Embark on a journey through the world of DTF Transfers and discover how they are transforming the landscape of garment printing.

Understanding Direct-to-Film Printing Technology

Direct-to-Film (DTF) printing technology represents a major advancement in the realm of garment printing. By leveraging specialized films and high-quality inks, this method provides a unique solution to some of the limitations seen in traditional printing techniques. DTF printing not only allows for intricate designs with vibrant colors but also accommodates a wide range of fabric types, making it an ideal choice for custom apparel production. This versatility enables businesses to cater to diverse customer preferences and market demands.

The flexibility of DTF printing is a game changer for textile printing innovations. Whereas other methods may falter on certain materials, DTF excels, confidently printing on both light and dark fabrics alike. This attribute fuels its appeal across various segments, from small, custom print shops to large-scale textile manufacturers. As the industry evolves, DTF continues to lead with its unique ability to bridge the gap between quality and practicality.

The Step-by-Step DTF Printing Process

At the heart of DTF printing lies a meticulously crafted process that ensures exceptional results. Initially, the design creation step involves utilizing graphic design software to conceptualize a visually striking image. The quality of the design set a precedent for the final output, and it is crucial that this step reflects the intricacies of the intended print. Following this, the design is printed onto a special DTF film using top-grade water-based inks, which play a critical role in achieving the desired vibrancy and detail.

The subsequent transfer process showcases the richness of the DTF printing technique. After the film receives an application of powdered adhesive, it undergoes curing through a heat press, which prepares it for application onto the fabric. This multi-step process guarantees that the final products not only boast bright colors but also durability and resilience in the face of laundry cycles. This streamlined approach positions DTF printing as a more efficient alternative to other garment printing technologies.

Advantages of Using DTF Transfers in Custom Apparel

One of the most compelling reasons to adopt DTF transfers in custom apparel production is the remarkable quality it delivers. DTF printing excels at producing vivid colors and sharp details, paving the way for stunning graphic representations. This level of quality is particularly advantageous for businesses that aim to leave a lasting impression on their clientele; custom designs can be brought to life with a precision that meets or exceeds customer expectations.

Moreover, the material versatility of DTF is unparalleled. Whether working with cotton, polyester, or even blended materials, DTF technology proves to be adaptable across diverse fabrics. This broad compatibility not only streamlines the printing process for decorators but also ensures that they can meet various client needs without compromising on quality or aesthetics. Additionally, the cost-effectiveness of DTF for small runs makes it an attractive option for emerging businesses looking to minimize overhead while maximizing creativity.

Exploring Market Growth and Consumer Trends in DTF Printing

Recent years have witnessed significant growth in the DTF printing market, propelled by a surge in e-commerce and consumer demand for personalized apparel. Businesses that adopt DTF technology can leverage its efficiency to create tailor-made designs that cater to specific customer preferences. This level of customization has proven essential in a retail landscape marked by rapid changes in consumer behavior and expectations.

Furthermore, the rise of social media and online platforms has amplified the demand for unique and eye-catching apparel. DTF printing aligns perfectly with these trends, allowing brands to quickly respond to market fluctuations and customer requests. The ability to produce high-quality, customized items in a timely manner positions businesses at a competitive advantage, facilitating a deeper connection with their customer base.

Future Directions in DTF Technology and Sustainability Initiatives

As the awareness around environmental issues grows, the future landscape of DTF technology is likely to embrace sustainability initiatives. The potential introduction of biodegradable materials and non-toxic inks could not only satisfy eco-conscious consumers but also comply with increasingly stringent environmental regulations within the textile industry. This shift towards sustainability represents a significant opportunity for businesses to differentiate themselves in a crowded market.

In addition to integrating sustainable practices, the evolution of DTF printing will likely involve enhancements in technology that improve speed and print quality. With continuous advancements, manufacturers can expect smarter printers and inks that enhance both efficiency and output. These improvements aim to support businesses in keeping pace with growing demands while maintaining the high standard of quality that has become synonymous with DTF printing.

Integrating DTF Printing with Digital Platforms and E-commerce

The intersection of DTF printing with digital platforms presents exciting opportunities for businesses to streamline operations and enhance customer experiences. Automation of design submission and order processing through e-commerce platforms can significantly reduce turnaround times for customized apparel. This fusion of DTF technology with digital marketplaces will empower brands to remain agile and responsive in a fast-paced retail environment.

Moreover, the growth of online shopping highlights the need for seamless integration between production and customer service. By adopting DTF printing in conjunction with digital solutions, businesses can create a more engaging consumer experience that incorporates personalization and ease of access. Such innovations not only improve operational productivity but also foster brand loyalty as customers enjoy a more tailored shopping journey.

Frequently Asked Questions

What are DTF transfers in garment printing technologies?

DTF transfers, or Direct-to-Film transfers, represent a cutting-edge garment printing technology that allows designs to be printed on a special film before being transferred onto fabric. This method is renowned for its vibrant colors, intricate details, and the ability to work with various fabric types, making it a popular choice in custom apparel production.

How does the DTF printing process work?

The DTF printing process involves several key steps: first, designs are created digitally; next, they are printed onto a special film using high-quality water-based inks. Afterward, a powdered adhesive is applied, and the design is cured with heat. Finally, the design is transferred onto the fabric using a heat press, resulting in durable and vivid prints.

What are the advantages of using DTF printing for custom apparel production?

DTF printing offers multiple advantages, such as vibrant, high-density colors, the ability to print on a wide range of fabrics, a simplified workflow that eliminates pre-treatment, and cost-effectiveness for small batch orders. This makes it an ideal choice for custom apparel production by businesses and retailers.

Is DTF printing suitable for all types of fabrics?

Yes, DTF printing is particularly versatile and can be used on various fabric types, including cotton, polyester, and blended materials. This flexibility allows garment decorators to effectively cater to diverse customer needs in the custom apparel market.

What trends are emerging in the world of DTF transfers and textile printing innovation?

Emerging trends in DTF transfers include a focus on sustainability practices, enhancements in print quality and speed, and integration with digital platforms to streamline order processing. These trends are reshaping the landscape of textile printing and enhancing consumer experiences.

How can businesses leverage DTF printing for e-commerce success?

Businesses can leverage DTF printing in e-commerce by integrating it with online shopping platforms for seamless order processing and design submissions. This facilitates personalized offers, quick turnaround times, and keeps pace with evolving consumer preferences in custom apparel.

| Key Points | Details |

|---|---|

| Emergence of DTF Technology | Introduced in the late 2010s, DTF printing integrates the strengths of traditional screen printing and DTG printing, providing vibrant, high-quality prints. |

| DTF Printing Process | Involves design creation, printing on special film, applying powdered adhesive, and transferring designs onto fabric with heat and pressure. |

| Market Growth and Adoption | The rise of e-commerce and personalized apparel has increased the demand for DTF printing among small businesses to large manufacturers. |

| Advantages of DTF Transfers | Includes bright colors, material versatility, a simplified workflow, and cost-effectiveness for small runs. |

| Future Trends in DTF Technology | Emphasizes sustainability initiatives, enhanced quality and speed, and integration with digital platforms for better consumer experiences. |

Summary

DTF Transfers have revolutionized the textile printing industry through their innovative approach and transformative capabilities. With roots tracing back to the late 2010s, this technology has evolved significantly, meeting the demands of an increasingly personalized consumer market. As DTF printing continues to gain traction, its focus on vibrant color reproduction across various materials, and its ability to streamline production processes ensure it remains competitive against traditional methods. Businesses, regardless of size, can leverage DTF Transfers to enhance their custom garment offerings while exploring future trends such as sustainability and integration with digital platforms. In conclusion, DTF Transfers not only highlight a shift in printing technology but also promise a vibrant future for creativity and customization in the apparel industry.