In the vibrant world of textile printing, **DTF transfers** (Direct to Film transfers) have emerged as a revolutionary technology, capturing the attention of both seasoned professionals and newcomers. Known for their exceptional print quality and durability, DTF transfers challenge the traditional norms of the industry by offering versatile solutions for various fabric types. However, despite their growing popularity, a myriad of myths surrounding DTF printing continues to persist, often leading to confusion among potential users. In this article, we will uncover five common misconceptions about DTF transfers, clarify the realities regarding their durability, and explore the compatibility of DTF materials. By addressing these myths, we aim to empower beginners in their DTF printing journey and highlight the advantages of this innovative process that is redefining custom apparel creation.

When discussing fabric printing techniques, many enthusiasts encounter the term “Direct to Film transfers,” often abbreviated as DTF. This cutting-edge printing method is favored for its ability to produce high-quality designs that adhere seamlessly to various textiles. As with any emerging technology, several misunderstandings exist that can deter individuals from utilizing its full potential, especially among beginners. By demystifying the direct film printing process and addressing common queries about DTF transfer durability and materials compatibility, we can foster a better understanding of why this technology is becoming the go-to choice for custom garment production. Through this examination, both hobbyists and small operations can confidently embrace the world of beginner DTF printing.

Understanding DTF Transfers: The Reality Behind Their Durability

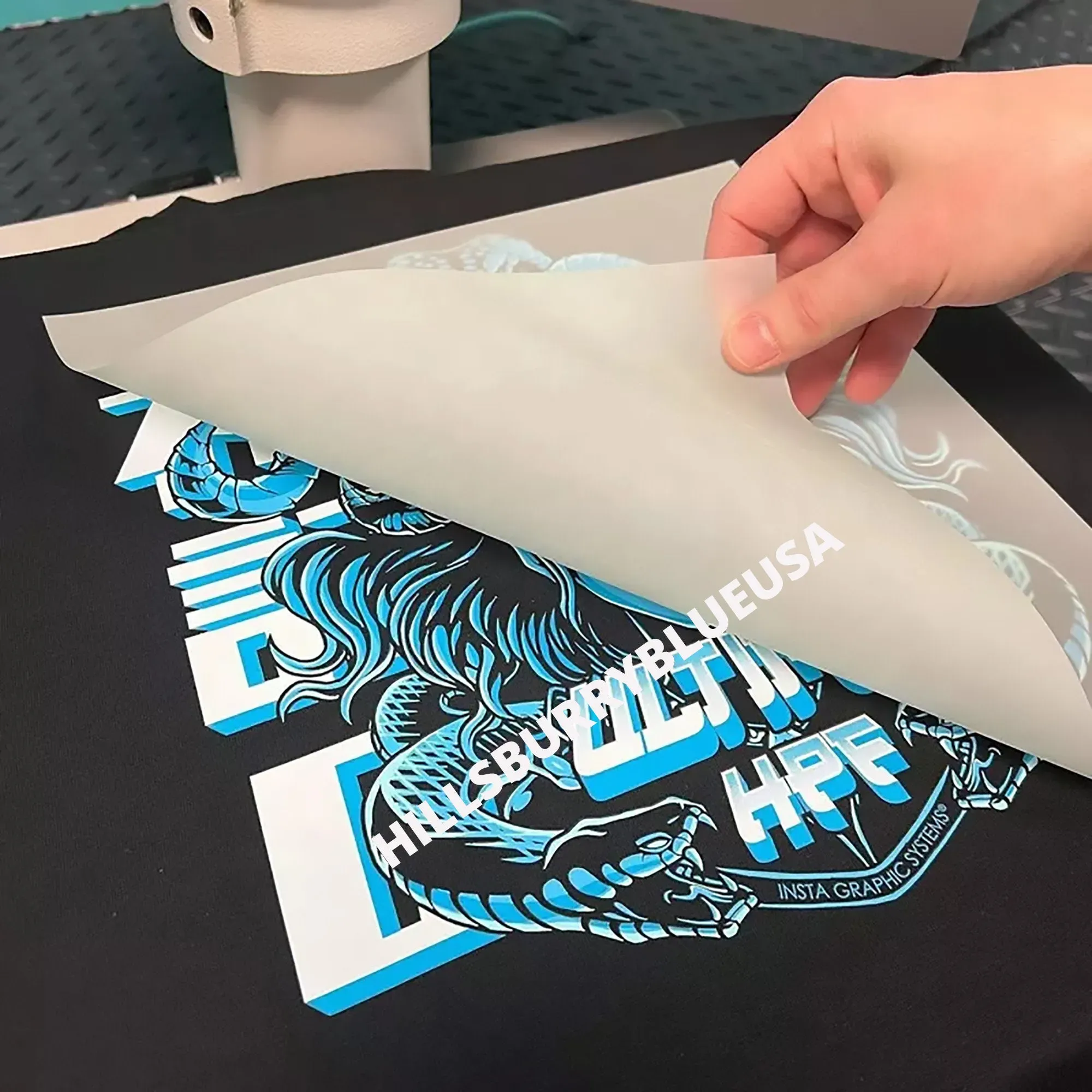

One of the most significant advantages of DTF transfers is their impressive durability. Contrary to the myth that has clouded their reputation, DTF prints are designed to withstand the rigors of everyday wear. They resist fading, cracking, and peeling, delivering vibrant results that can endure multiple washes without losing their quality. This durability reaffirms DTF’s position as a legitimate contender in the textile printing market, offering a reliable solution for custom apparel that ranges from casual wear to professional uniforms.

Moreover, numerous industry reports, such as those from Printwear Magazine, emphasize the importance of proper application techniques in maximizing the longevity of DTF prints. Users who follow recommended methods ensure that their prints maintain their integrity over time. This capacity for durability not only enhances customer satisfaction but also positions DTF transfers as an economically viable choice for businesses looking to reduce waste and maintain high standards in product quality.

Myth-Busting DTF Transfers: Material Compatibility Explored

A widespread misconception holds that DTF transfers are exclusive to cotton fabrics. However, the versatility of DTF technology allows for successful application across a wide range of materials, including polyester and other fabric blends. This compatibility opens up possibilities for creating intricate designs on various textile types, enabling designers to expand their creative horizons. As highlighted by U.S. DTF, the notion that DTF transfers are limited is largely exaggerated.

Additionally, the ability to use DTF on both light and dark fabrics expands the creative potential for artists and entrepreneurs alike. With DTF, users can produce a stunning array of custom designs tailored to diverse fabric options, ensuring that their creative vision comes to life, regardless of the material. This flexibility establishes DTF as an exceptional choice for anyone looking to produce high-quality prints on various substrates.

### Simplifying DTF Printing for Beginners: An Accessible Art Form

Despite the assumption that DTF printing is only for seasoned professionals, advancements in technology have made it remarkably accessible for beginners. Newer DTF printing machines come equipped with user-friendly interfaces, allowing novices to dive into the world of textile printing without feeling overwhelmed. Step-by-step guides and instructional content have proliferated online, significantly reducing the learning curve typically associated with new printing techniques.

Industry experts have pointed out that users can achieve professional-quality results even without extensive experience by following clear guidelines. Many beginner tutorials showcase the DTF printing process, breaking it down into manageable steps. This approach not only empowers newcomers but cultivates a community of enthusiastic creators eager to explore DTF’s potential in textile art, further contributing to its growing popularity.

Introducing DTF Transfers: Equipment Requirements and Accessibility

A common myth surrounding DTF transfers is the belief that it requires specialized equipment, which can deter many potential users. While traditional Direct to Garment (DTG) printing often necessitates a significant investment in advanced printers and inks, DTF printing presents a more adaptable solution. Many commercially available inkjet printers can be modified for DTF applications, allowing entry into this printing method without breaking the bank.

Stitches Magazine affirms that aspiring DTF printers can utilize common equipment, making the technology accessible for entrepreneurs and hobbyists alike. This adaptability not only democratizes the printing process but also inspires creativity among those who may have previously thought high-quality printing was out of reach. By encouraging users to use their existing resources, DTF printing fosters innovation and experimentation within the textile printing community.

Evaluating DTF Transfers: Cost-Effectiveness for Small Businesses

Many small business owners are often dissuaded from exploring DTF transfers due to concerns about costs. Although initial investment may seem intimidating, the cost per transfer can be surprisingly low, especially when compared to traditional screen printing methods. For short production runs, DTF’s economic advantages become apparent, enabling smaller operations to produce high-quality items efficiently without incurring significant costs.

Moreover, as reported by Screen Printing Magazine, when considering the long-term savings and enhanced productivity that DTF printing provides, it emerges as a cost-effective solution for small businesses. By minimizing overhead expenses while maximizing output quality, DTF transfers offer a sustainable option for those looking to thrive in the competitive world of custom apparel printing.

The Future of DTF Transfers: Dispelling Misconceptions

As the textile printing industry evolves, staying informed and debunking prevailing myths becomes crucial. Understanding the true capabilities of DTF transfers can unlock unleashing the full potential of this innovative technology. By addressing common misconceptions, we pave the way for a new generation of printing professionals who can leverage DTF’s versatility, durability, and affordability to create stunning, high-quality designs.

Education and awareness within the community are paramount in transforming perceptions and encouraging broader acceptance of DTF printing. As more individuals obtain accurate information about DTF, including its material compatibility, ease of use, and cost-effectiveness, the myths that have historically surrounded this printing method will gradually dissipate. Embracing the realities of DTF transfers firmly establishes them as a reliable cornerstone within modern textile printing.

Frequently Asked Questions

What are the common myths about DTF Transfers?

Many common myths about DTF Transfers include misconceptions about their durability, material compatibility, and complexity for beginners. For instance, some believe DTF transfers aren’t durable, but they can actually rival screen printing in longevity. Others think DTF transfers only work on cotton, but they are versatile enough for polyester and blends. Understanding these myths helps in fully appreciating the capabilities of DTF printing.

How durable are DTF Transfers compared to other printing methods?

DTF Transfers are known for their exceptional durability, often withstanding multiple washes without significant wear or fading. This makes them comparable to traditional screen printing. Proper application techniques enhance their longevity, ensuring high-quality results that last.

Can DTF Transfers be used on materials other than cotton?

Yes, DTF Transfers can be used effectively on a variety of materials beyond cotton, including polyester and fabric blends. This adaptability allows printers to create vibrant designs on both light and dark fabrics, making DTF technology very versatile in textile printing.

Is DTF printing suitable for beginners?

Absolutely! Although some believe DTF printing is too complicated for beginners, advancements in technology have made it more user-friendly. Many DTF printers come with simplified settings, allowing newcomers to achieve high-quality prints without extensive training.

Do I need special printers and inks for DTF Transfers?

While some printing methods require specialized equipment, DTF Transfers can often utilize modified inkjet printers and specially formulated DTF inks. This accessibility allows small businesses and DIY enthusiasts to engage easily in DTF printing without needing a significant upfront investment.

Are DTF Transfers cost-effective for small operations?

DTF Transfers can be very cost-effective for small operations. The cost per transfer is lower than traditional methods like screen printing, particularly for short runs. Over time, the efficiency and high-quality output of DTF printing contribute to long-term savings, making it a viable option for smaller scale projects.

| Myth | Reality |

|---|---|

| DTF Transfers Aren’t Durable | DTF transfers are highly durable and can compete with traditional screen printing in longevity. |

| DTF Transfers Only Work on Cotton Fabrics | DTF transfers work on various materials, including polyester and fabric blends. |

| DTF Transfer Processes Are Too Complicated for Beginners | DTF printing has become user-friendly with simplified machines and guides. |

| DTF Transfers Require Special Inks and Printers | DTF can utilize modified inkjet printers and specially formulated inks. |

| DTF Transfers Are Too Expensive for Small Operations | The cost per transfer is low, making DTF a viable option for small operations. |

Summary

DTF Transfers have revolutionized the textile printing industry by providing high-quality, durable prints at a competitive cost. People often hold onto myths that mischaracterize this technology, such as its durability or material limitations. By understanding that DTF transfers are versatile and cost-effective, more businesses and hobbyists can embrace this innovative method. As these misunderstandings are debunked, the potential for DTF transfers in custom apparel and beyond will become increasingly recognized, ensuring this printing method continues to gain momentum.