In the realm of custom apparel printing, DTF gangsheets stand out as a game-changer for creators looking to streamline their production process. Combining the innovative Direct-to-Film printing technique with the efficiency of gangsheets allows for multiple designs to be printed simultaneously, saving both time and resources. This method not only enhances workflow but also ensures vibrant, high-quality prints that appeal to a wide range of fabric types. As we delve deeper into how to create DTF gangsheets, we will uncover the benefits they offer and how they can elevate your custom designs. By mastering the DTF printing process, you can unlock a new level of creativity in your apparel projects.

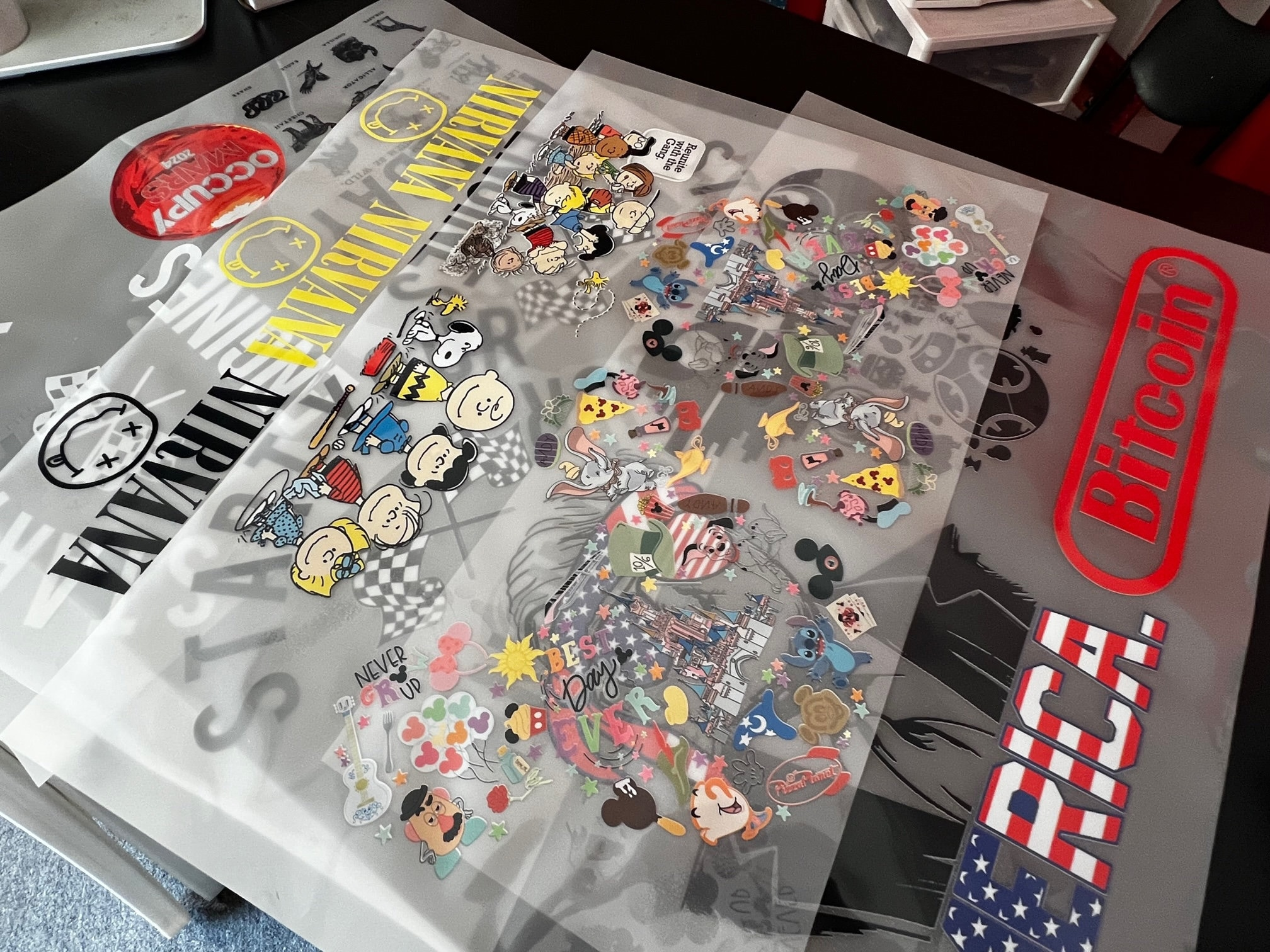

DTF gangsheets, also referred to as Direct-to-Film sheets, are revolutionizing the way graphic designers and apparel printers approach production. These versatile sheets enable users to print various designs on a single film, making them an essential tool for efficient manufacturing. Whether you’re exploring the essentials of creating custom fabric graphics or you seek a detailed gangsheets tutorial, understanding the fundamentals of this printing method will greatly enhance your capabilities. From first impressions to the final transfer, the process of making DTF sheets aligns perfectly with the needs of modern custom apparel production, providing a seamless solution for both creators and businesses alike.

Understanding Direct-to-Film Printing

Direct-to-Film (DTF) printing is a revolutionary technology that enhances the custom apparel printing experience. Unlike traditional methods, DTF printing involves printing designs onto a special film which is then transferred onto fabrics. This method is known for its high-quality prints, vibrant colors, and excellent durability, making it a favorite among print shops. With DTF, the design process is efficient, allowing for a seamless transition from digital artwork to actual products without compromising quality.

The DTF printing process begins with preparing the film and ensures that the appropriate inks and printer settings are used to guarantee the best result. Whether you are dealing with intricate graphics, detailed text, or vibrant images, DTF printing can handle diverse designs effortlessly, making it an essential tool for any custom apparel business looking to elevate their offerings.

Frequently Asked Questions

What are DTF gangsheets and how are they used in custom apparel printing?

DTF gangsheets, or Direct-to-Film gangsheets, are sheets designed to print multiple designs at once in the DTF printing process. This technique is particularly advantageous for custom apparel printing as it maximizes efficiency by saving materials and time, allowing various designs to be simultaneously transferred onto garments.

How can I create DTF gangsheets for my printing business?

Creating DTF gangsheets involves several steps: start by using graphic design software to arrange multiple designs on a single sheet, optimize the color profiles for DTF printing, print using a DTF printer, apply hot melt powder adhesive, and complete the transfer to fabric. Following these steps ensures high-quality results for custom apparel.

What are the advantages of using DTF printing with gangsheets?

The advantages of using DTF printing with gangsheets include cost-effectiveness, versatility across different fabric types, and the ability to produce high-quality and durable prints. By printing multiple designs on one sheet, businesses can reduce waste and lower production costs, making it ideal for custom apparel.

What materials do I need to print DTF gangsheets?

To print DTF gangsheets, you will need a DTF printer, DTF film, DTF inks, hot melt powder adhesive, and graphic design software such as Adobe Illustrator. These materials are essential for creating vibrant and durable designs for custom apparel.

Can you provide a quick overview of the DTF printing process involving gangsheets?

The DTF printing process involving gangsheets begins with designing your artwork and arranging it on a film sheet. Next, print using a DTF printer, apply a hot melt powder adhesive, and cure the prints. Finally, transfer the designs onto the fabric using a heat press, followed by peeling the film to reveal the finished product.

Where can I find tutorials on creating DTF gangsheets?

Tutorials on creating DTF gangsheets are widely available online, including comprehensive guides like this one. You can find step-by-step videos and articles that cover aspects of the DTF printing process, from design to final transfer, ensuring that you have the necessary knowledge to produce professional-quality custom apparel.

| Key Point | Details |

|---|---|

| What Are DTF Gangsheets? | Film sheets allowing multiple designs to print simultaneously. |

| Benefits | 1. Cost-Effective: Reduces material and labor costs. 2. Versatile: Works with various fabric types. 3. High Quality: Produces durable and vivid designs. |

| Step 1: Gather Materials | Use graphic design software and high-resolution graphics. |

| Step 2: Create & Arrange Designs | Set up canvas size and arrange designs optimally. |

| Step 3: Optimize Color Profiles | Use CMYK settings for best print output. |

| Step 4: Print Designs | Load DTF printer with film and print designs. |

| Step 5: Apply Adhesive Powder | Sprinkle hot melt powder on wet prints and cure. |

| Step 6: Transfer Designs | Use a heat press to transfer to fabrics. |

| Step 7: Peel and Finish | Peel the film and press again for durability. |

Summary

DTF gangsheets are a revolutionary approach to creating custom apparel, combining efficiency with high-quality output. By utilizing the step-by-step guide provided above, anyone from beginners to seasoned printers can easily create vibrant and durable designs without hassle. The cost-effectiveness and versatility of DTF gangsheets not only enhance the production process but also open up new opportunities in the world of custom printing. Whether for personal projects or business purposes, mastering DTF gangsheets will undoubtedly elevate your printing game.