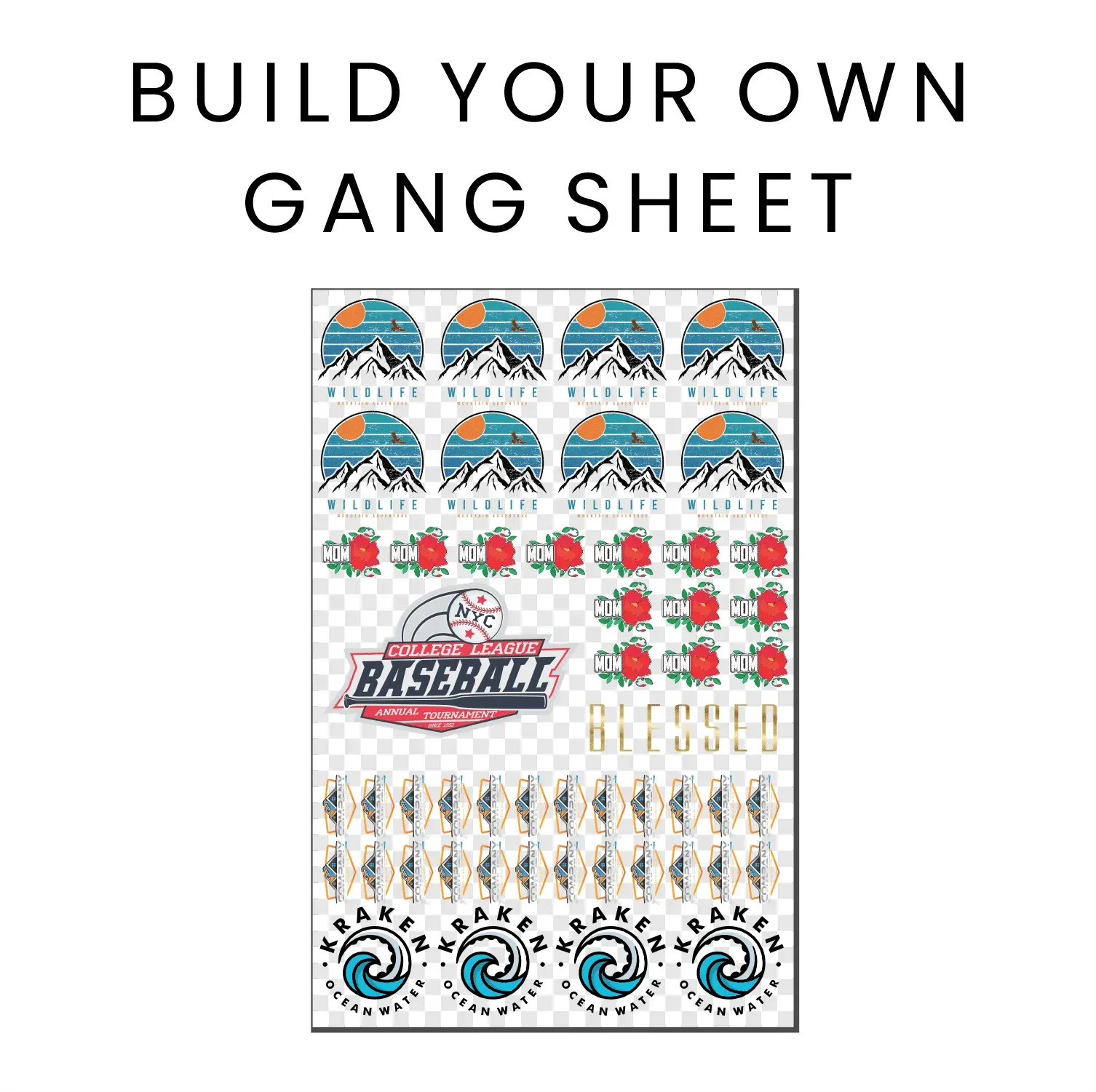

The **DTF gangsheet builder** is revolutionizing the way custom designs are produced in the textile industry, providing a seamless process for Direct-to-Film (DTF) printing enthusiasts. This innovative tool allows users to create efficient gang sheets that maximize the print area while minimizing waste, enhancing their overall printing experience. With its ability to manage color effectively and adjust printing and curing settings, the DTF gangsheet builder is a game-changer for those looking to achieve stunning, high-quality prints. As more businesses seek cost-effective solutions that deliver vibrant results, mastering this tool will prove essential to standing out in a competitive market. In this guide, we will explore the integral aspects of using this remarkable builder, ensuring you harness its full potential and elevate your DTF printing skills.

Introducing the innovative tool for Direct-to-Film (DTF) printing, the gangsheet creator streamlines the design process, allowing for multiple prints to be arranged efficiently on a single transfer film. This method, often referred to as gangsheet creation, enhances production capabilities by optimizing space and reducing costs in the printing workflow. With advanced color management features and tailored printing software, the gangsheet creator empowers users to achieve professional-quality prints with ease. By understanding printing and curing settings alongside design arrangements, anyone can elevate their printing output. This introduction sets the stage for a deeper dive into mastering the essential elements of creating successful DTF prints.

DTF Printing Explained: A Beginner’s Guide

Direct-to-Film (DTF) printing is an innovative technique that combines digital printing with heat transfer, allowing for intricate and colorful designs to be transferred directly onto textiles. This method involves a series of steps starting from design creation to the final transfer onto fabrics. Understanding each stage — from graphic design created in specialized DTF printing software to the printing of images on transfer films — is essential for achieving optimal results. The application of adhesive powder and the curing process further ensure that the print adheres effectively to the material, leading to vibrant and durable outputs.

For those new to DTF printing, it is vital to grasp the entire workflow, as any mistakes in early stages could result in wasted materials and lost time. From ensuring the quality of the design file to the careful execution of each intermediate step, knowing the fundamentals will empower you to create impressive prints that elevate your business profile in the highly competitive textile industry.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it work?

A DTF gangsheet builder is a tool that allows users to arrange multiple designs on a single film sheet for Direct-to-Film (DTF) printing. It optimizes space usage by efficiently organizing designs, enabling cost-effective printing and reducing material waste. By utilizing the DTF gangsheet builder, users can streamline their printing process and enhance production efficiency.

How do I select the best DTF printing software for gangsheet creation?

Choosing the right DTF printing software for gangsheet creation is essential for optimal results. Look for software with features such as high-resolution support, built-in templates for arrangement, and effective color management systems. Popular choices include Adobe Illustrator and DTF-specific programs, which allow you to easily create and format gang sheets that meet your printing needs.

What should I consider for color management in DTF printing with a gangsheet builder?

Effective color management in DTF printing is vital for achieving vibrant outputs. When using a gangsheet builder, utilize compatible color profiles and perform test prints on varied materials to assess color accuracy. Adjustments may be necessary based on test results to ensure your prints reflect the intended designs accurately and satisfy customer expectations.

What are the optimal printing and curing settings for DTF gangsheet printing?

Optimal printing and curing settings are crucial for successful DTF gangsheet printing. Ensure your printer is calibrated, and follow manufacturer-recommended temperature and time settings for curing the adhesive. Incorrect settings can lead to poor adhesion, color issues, and durability problems, so it’s important to test and confirm settings for best results.

How can I troubleshoot common issues when using a DTF gangsheet builder?

Common issues when using a DTF gangsheet builder include ink smudging and color discrepancies. To troubleshoot, ensure adequate drying time before handling prints to prevent smearing, and reference your color management settings to adjust discrepancies. Monitoring your adhesive application and curing settings can also help eliminate potential problems effectively.

What are some tips for efficient gangsheet creation in DTF printing?

To create efficient gang sheets in DTF printing, utilize grid layouts to maximize design space and ensure optimal arrangement without overlap. Accurate measurement of your print area is key, as is maintaining adequate spacing between designs for easy handling. These practices reduce material waste and improve turnaround times, ensuring a streamlined production process.

| Key Point | Details |

|---|---|

| Introduction to DTF Printing | DTF printing offers cost-effective, high-quality textile printing, crucially enhanced by mastering the DTF gangsheet builder. |

| Understanding DTF Basics | Key steps include design creation, film printing, powder application, and curing. |

| Selecting Software | Use software like Adobe Illustrator that supports high-resolution images and has good layout tools. |

| Design Arrangement | Arrange designs using grid layouts with accurate measurements to minimize waste. |

| Color Management | Use compatible color profiles and conduct test prints for color accuracy. |

| Optimizing Settings | Regular calibration and correct temperature settings improve print quality. |

| Post-Processing | Trim with high-quality tools and store unused sheets properly. |

| Troubleshooting Issues | Common issues include ink smudging, adhesive problems, and color discrepancies. |

| Additional Tips | Engage with communities for support and stay updated on best practices. |

Summary

The DTF gangsheet builder is pivotal for anyone keen on excelling in DTF printing. Understanding the intricate processes from designing to troubleshooting is essential for crafting exceptional prints. By selecting the right software, mastering design arrangement, and implementing effective color management, you prepare yourself to optimize the entire printing cycle. As you refine your skills and utilize this guide, you’ll elevate your DTF printing capabilities, enabling you to capture stunning, professional-quality textile products that cater to the ever-growing demand in the market.