Welcome to the realm of textile innovation with the DTF Gangsheet Builder, a revolutionary tool that streamlines the art of DTF printing. This advanced builder allows designers to create gang sheets, efficiently consolidating multiple unique designs onto a single film for high-quality printing. Whether you’re engaged in a DTF printing tutorial or working on intricate gangsheet designs, mastering this technology can significantly reduce production time and costs. Seamlessly incorporating techniques in the DTF printing process, the Gangsheet Builder is your best ally for fulfilling custom apparel demands. Join us as we explore how to use the DTF Builder step-by-step to unleash your creativity in the world of textile printing.

In the vibrant landscape of modern printing techniques, the DTF Gangsheet Builder emerges as a key asset for those looking to enhance their design workflows. This tool excels in generating printable gang sheets, which efficiently combine multiple artwork designs into one print run. It’s no surprise that enthusiasts are eager to discover more about processes like Direct to Film printing and how to implement effective textile printing methods. By diving into this guide, you will learn essential textile techniques, including the intricacies of the DTF printing process, to elevate your projects. With a comprehensive understanding of how to harness this innovative builder, you’ll be well-equipped to produce standout creations in the garment industry.

Getting Started with DTF Printing: An Overview

DTF printing, or Direct to Film printing, is revolutionizing the textile industry by offering high-resolution prints that adhere perfectly to a range of fabrics. This method involves printing designs onto a special film, which can then be transferred onto garments using heat. One of the key advantages of DTF printing is its capability to produce vibrant colors and intricate designs that stand out. Understanding the basic principles of DTF enables designers and businesses to harness this technology effectively for their printing needs.

Additionally, mastering the DTF printing process requires comprehending the role of film preparation and adhesive application. The film acts as the intermediary, and proper preparation of both the film and adhesive application is critical for optimal print quality. By leveraging these steps, users can create vivid and long-lasting prints that cater to various custom apparel requests.

The Essential Features of the DTF Gangsheet Builder

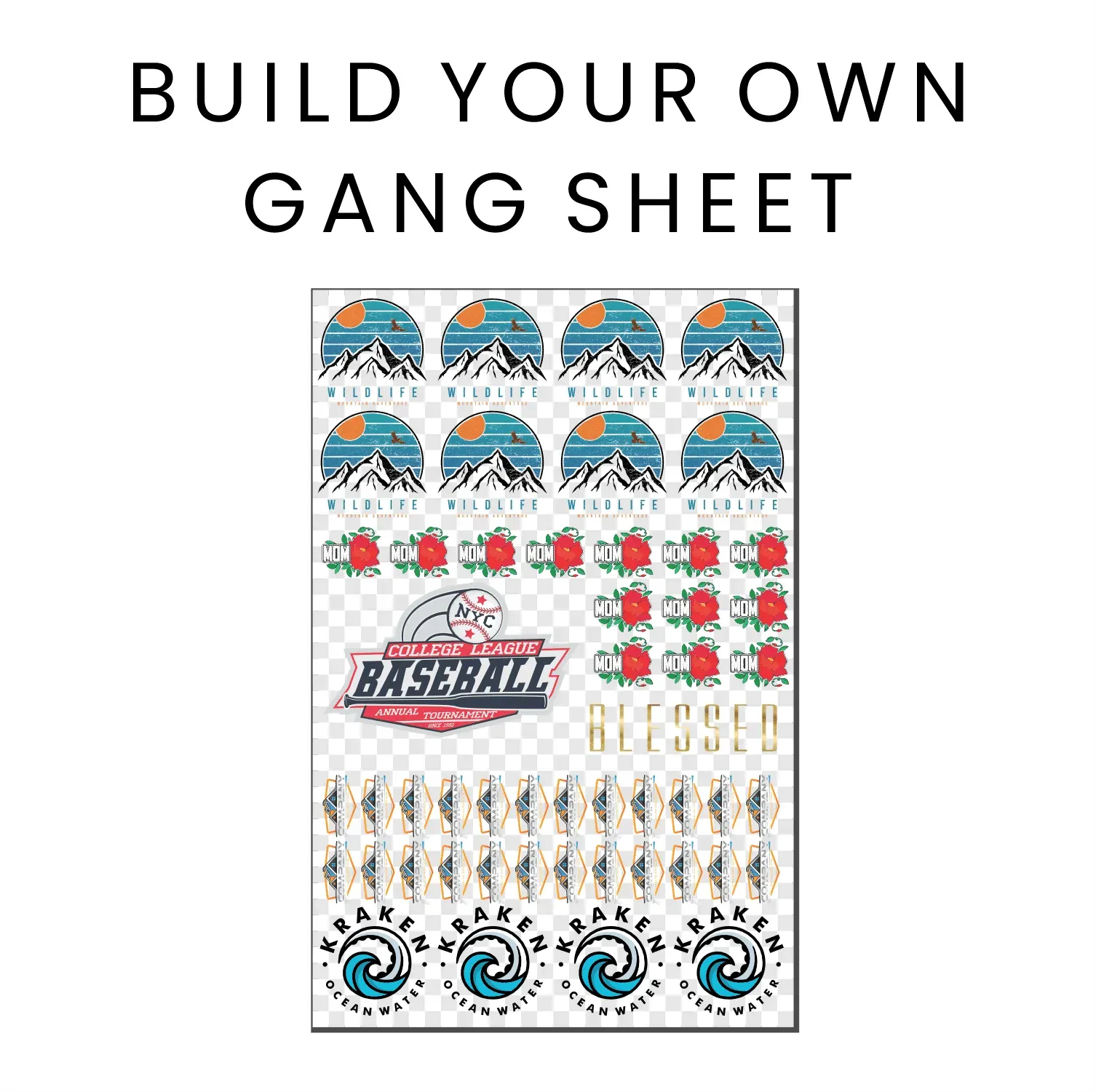

The DTF Gangsheet Builder is a powerful tool tailored for those looking to maximize their printing efficiency and design output. By allowing multiple designs to be printed on a single sheet, it not only optimizes material usage but also significantly reduces printing times. The ability to group various logos and illustrations together means that businesses can produce bulk orders without sacrificing design quality or detail.

Moreover, this tool simplifies the filing and printing process. Users can easily layout their designs digitally, ensuring that every inch of the gang sheet is utilized effectively. This feature is particularly advantageous for producing items such as t-shirts or promotional apparel, as it minimizes waste and maximizes productivity, making it an essential component for any serious printing business.

Step-by-Step Guide to Crafting Designs Using DTF Gangsheet Builder

Creating stunning designs for DTF printing starts with a solid understanding of the DTF Gangsheet Builder interface. Users begin by uploading their graphics into the design software, ensuring that each design is sized appropriately for the target garment. Familiarity with graphic design principles such as resolution and color modes greatly enhances the quality of the finished product. This step is critical because well-prepared designs directly influence the vibrancy and durability of the printed apparel.

After the designs are uploaded and adjusted, the next phase involves arranging them on the gang sheet. Careful consideration should be given to spacing and layout—this is where the true power of the DTF Gangsheet Builder shines. By utilizing templates, designers can ensure that each graphic maintains its integrity when printed on the film, leading to a flawless transfer process.

Optimizing Film Preparation for DTF Printing

Film preparation is a crucial stage in the DTF printing process that determines the overall quality of the printed designs. The DTF Gangsheet Builder aids in simplifying this phase by providing detailed guidelines on printer settings and film types. Using a high-quality PET film ensures that the prints adhere well to the fabric while retaining the colors vibrantly. Additionally, setting the printer to the correct options minimizes ink waste and maximizes clarity.

An equally important aspect of film preparation involves the calibration of the printing equipment. Users must ensure that their DTF printer settings are calibrated to produce the best output quality. Adjusting parameters such as ink density and paper type can significantly impact the success of a print run. By taking the time to optimize these settings, designers can guarantee impressive results every time.

Understanding Adhesive Powder Applications in DTF Printing

Applying the adhesive powder is a pivotal moment in the DTF printing process, as it ensures that the ink effectively bonds with the fabric during the heat transfer. The use of a high-quality DTF adhesive powder should be accompanied by uniform distribution across the printed design. The DTF Gangsheet Builder streamlines this process, offering detailed instructions for achieving an even application, which is vital for ensuring consistent results throughout the print run.

Moreover, timing is of the essence when it comes to powder application. Since the powder needs to be applied while the ink is still wet, designers must work swiftly yet meticulously to ensure optimal adhesion. This crucial step not only affects the durability of the print but can also determine the overall success of the design on various fabric types.

Final Steps: Curing and Transferring Designs with DTF

Curing the film before transferring it to the garment is an essential process that enhances the adhesive’s bonding capabilities. This step involves applying heat to the printed film, causing the adhesive powder to melt and fuse with the ink on the film. Effective utilization of temperature and timing is crucial for this process, as overly high heat can damage the design, while inadequate heat may lead to poor adhesion. The DTF Gangsheet Builder provides guidelines for the best-curing practices tailored to the types of adhesives used.

Once the film is cured, the actual transfer to the garment is initiated. This step is where all prior preparations culminate in a final product. Adequate pressure and precise temperature settings are vital for ensuring that the design adheres perfectly to the fabric. Following the recommended pressing times helps ensure a durable result. Finally, a quality check provides assurances that the design meets both aesthetic and functional expectations.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a specialized tool designed for creating gang sheets in DTF printing. It allows users to combine multiple designs into one print job, optimizing material usage and efficiency. By utilizing this builder, you can save time and reduce costs while producing vibrant, high-quality prints on various fabrics.

How can I effectively use the DTF Gangsheet Builder for my designs?

To effectively use the DTF Gangsheet Builder, start by creating high-quality designs in graphic software like Adobe Illustrator, ensuring they are in CMYK mode with at least 300 DPI resolution. After preparing your designs, follow the step-by-step printing process, including film preparation, adhesive application, and heat transfer. This method allows you to maximize the use of materials and streamline production.

What are the benefits of using DTF printing with the Gangsheet Builder?

Using DTF printing alongside the Gangsheet Builder provides several benefits, including the ability to print multiple designs on a single sheet, which reduces waste and production costs. The DTF printing process also offers excellent color vibrancy and high-resolution output, making it ideal for custom apparel and bulk orders.

What textile printing techniques are commonly used with the DTF Gangsheet Builder?

The DTF Gangsheet Builder primarily utilizes DTF printing techniques, which involve printing designs onto a special film, applying adhesive powder, and transferring the design onto the fabric through heat application. This method is known for its efficiency and quality, making it suitable for various textile materials.

Can I use the DTF Gangsheet Builder for small-scale projects?

Yes, the DTF Gangsheet Builder is versatile and can be utilized for both small-scale projects and large production runs. Whether you’re printing custom t-shirts for an event or fulfilling bulk orders, this tool efficiently helps you create stunning designs while minimizing material waste.

What should I consider when creating gangsheet designs for DTF printing?

When creating gangsheet designs for DTF printing, consider factors such as design resolution (at least 300 DPI), color mode (CMYK for accuracy), and the overall size based on the garments you’ll be printing on. Proper film preparation and adhesive application are also crucial for ensuring the final prints adhere properly and maintain quality.

| Key Points | Details |

|---|---|

| What is DTF Printing? | A technique where designs are printed on a film, allowing intricate graphics to be transferred onto fabrics. |

| What are Gang Sheets? | A method of printing multiple designs on a single sheet, reducing waste and operational costs. |

| Step 1: Design Creation | Use graphic design software, ensuring CMYK format, high-resolution, and scalable sizes. |

| Step 2: Film Preparation | Set printer settings and arrange multiple designs efficiently on PET film. |

| Step 3: Powder Adhesive Application | Sprinkle DTF adhesive powder evenly over wet ink for proper bonding. |

| Step 4: Curing the Film | Heat press film to melt adhesive powder, ensuring effective adhesion. |

| Step 5: Heat Transfer to Garment | Preheat press, apply right pressure and time for transfer, and cool before peeling. |

| Step 6: Quality Check | Inspect for flaws and conduct wash tests to verify durability. |

Summary

The DTF Gangsheet Builder is your ultimate solution for transforming creative ideas into stunning textile designs. By understanding the process of DTF printing and mastering the art of gang sheets, you can streamline production while maintaining high-quality results. This comprehensive guide walks you through every essential step, from design creation to final quality checks, empowering you to produce vibrant, durable prints efficiently. As you embark on your DTF printing journey, remember that each design is a showcase of your creativity and craftsmanship. Engage with the community for continuous learning and inspiration, ensuring your skills evolve with the latest techniques and trends. Happy crafting!