DTF costs are a major consideration when starting or scaling a direct-to-film printing operation. Understanding where money goes helps you budget effectively, choose the right equipment, and price products competitively, which in turn supports smarter marketing, staffing choices, and inventory planning. In this guide, we break down the true cost of ownership for DTF printing costs, from the initial equipment investment to ongoing material expenses and daily operating costs, including routine maintenance and occasional downtime. By focusing on cost drivers such as films, inks, powders, electricity, and waste reduction measures, you can forecast margins and avoid surprises day by day. Knowing the cost framework helps you make smarter supplier decisions, optimize production, and protect profitability as you grow, while maintaining quality that keeps customers coming back.

To approach this topic from a broader angle, think in terms of production expenses for direct-to-film printing rather than a single sticker price. Key cost drivers include equipment investment, consumables, energy, maintenance, and staff time, all of which shape the price per garment. Framing the discussion around startup outlay, recurring outlays, and depreciation helps small shops plan for growth without surprises. This LSI-aware framing connects gear choices, material quality, workflow efficiency, and the value offered to customers.

DTF Costs Demystified: A Comprehensive Budget Breakdown

DTF costs are driven by several core categories: initial equipment investment, materials, and ongoing operating costs. Understanding these elements helps you estimate the total cost of ownership and plan for growth, aligning with the broader DTF printing costs you’ll encounter.

By breaking costs into fixed and variable components, you can forecast DTF costs over time and decide when to upgrade equipment, negotiate supplier terms, or adjust pricing to maintain healthy margins.

DTF Equipment Budget: How to Choose and Price Your Hardware

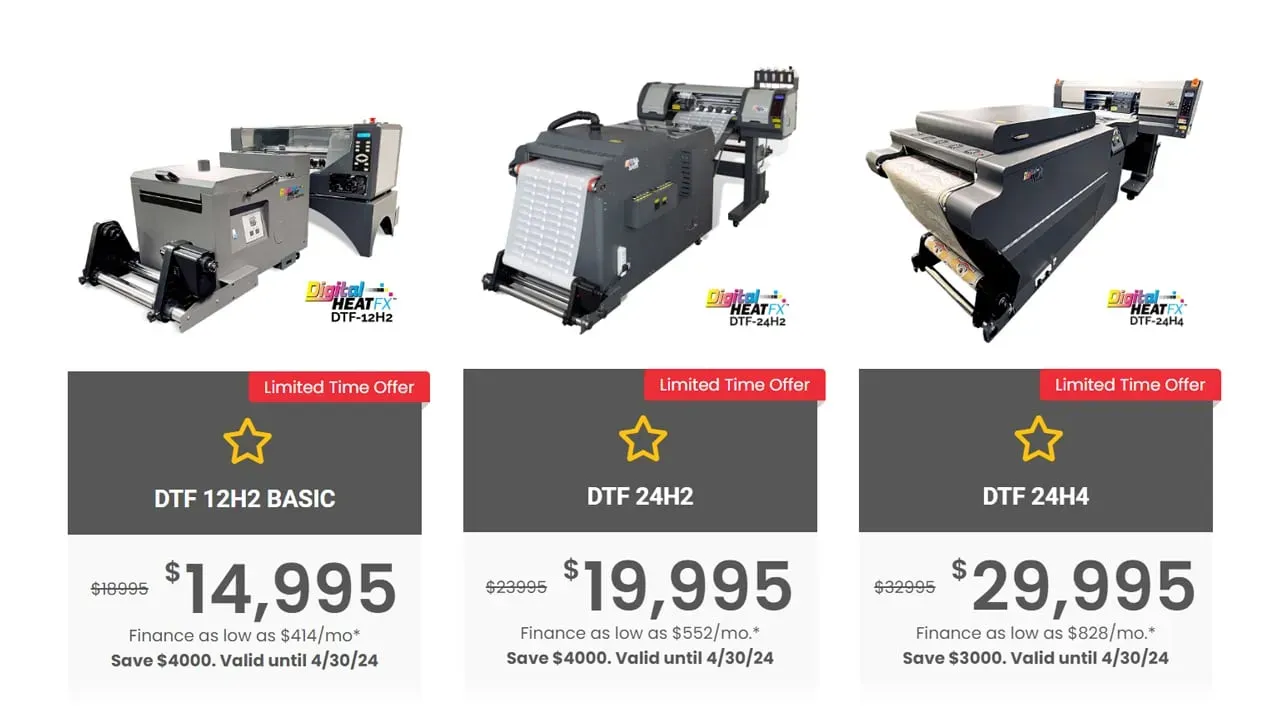

Your DTF equipment budget should cover a printer capable of CMYK plus white ink and a reliable heat press. Price ranges vary, so select models that balance print quality, reliability, and after-sales support to optimize the overall DTF printing costs.

Don’t neglect depreciation, warranties, and upgrade paths. A thoughtful DTF equipment budget minimizes downtime, supports consistent throughput, and lowers long-term costs per shirt.

DTF Materials Costs: Films, Inks, and Powders

Materials dominate ongoing expenses. DTF films, transfer sheets, white and CMYK inks, adhesive powder, and curing supplies are the main drivers of DTF materials costs and have a strong impact on your per-shirt pricing.

Waste, color coverage, and production efficiency all influence material costs, so track consumption per design and scale purchases to monthly production to keep DTF cost per shirt predictable.

DTF Ink Cost and Color Strategy for Lower Per-Unit Expenses

Ink costs are a major driver of per-shirt pricing. White ink especially can be costly, and the DTF ink cost scales with coverage, color saturation, and print area.

Adopt color optimization strategies, reduce unnecessary color changes, and batch similar designs to minimize ink waste and curing time, aligning with your broader cost-per-shirt goals.

Calculating DTF Cost Per Shirt: A Simple, Repeatable Method

A reliable method separates fixed and variable costs and amortizes equipment value across expected monthly output. This is the foundation for calculating DTF cost per shirt and planning pricing strategy.

Use a straightforward formula and plug in real shop data to see profitability. Adjust for throughput, waste, and downtime to reflect true operating costs.

Budget-Friendly Practices to Reduce DTF Costs without Compromising Quality

Start with a scalable setup and bulk purchases to lower the fixed and variable costs associated with DTF costs. Batch processing also reduces setup time and labor per shirt.

Invest in regular maintenance, diversify suppliers, and plan equipment lifecycles to extend asset life and minimize unexpected downtime, keeping the DTF equipment budget under control while maintaining quality.

Frequently Asked Questions

What are the main drivers of DTF costs and how do they influence the DTF cost per shirt?

DTF costs are driven by five core categories: equipment investment, materials and consumables, ongoing operating costs, labor/time, and overhead/depreciation. The DTF cost per shirt is found by allocating fixed costs (equipment depreciation, overhead) across monthly output and adding variable costs (consumables, energy, labor). For example, producing 600 shirts per month with $300 in equipment depreciation, $150 in overhead, $0.60 per shirt for consumables, $0.25 per shirt for energy, and $0.50 per shirt for labor yields a total cost per shirt of about $2.10.

How should I structure my DTF equipment budget to control long-term costs?

Start with the total cost of ownership: choose a scalable setup (printer, heat press, software), and plan depreciation over the gear’s useful life. Budget for monthly depreciation, maintenance, and potential repairs. For instance, if you budget a reasonable depreciation line for a mid-range printer and a quality heat press, you should expect a fixed monthly amount that translates into a small per-shirt figure once monthly output is known, helping you set prices that protect margins even as you grow.

How do DTF printing costs break down for a beginner setup, including DTF materials costs and equipment budget?

For beginners, the equipment budget typically covers a printer (roughly $3,000–$6,000) and a heat press ($800–$2,000). Materials costs—the largest recurring expense—include films/transfer sheets, inks (CMYK plus white), adhesive powder, and curing/finishing supplies. Material costs per shirt vary with color count and fabric but commonly fall within a few tenths to a couple dollars per shirt, making up a big portion of the DTF cost per shirt.

How does DTF ink cost affect pricing and profitability, and how can I manage it effectively?

DTF ink cost is a major component of materials costs and scales with color usage and fabric coverage, with white ink being especially critical on dark garments. Manage it by optimizing color usage (fewer colors, batch processing), selecting efficient printers, buying inks in bulk or through cost-effective options, and calibrating designs to minimize waste. These practices help keep the DTF costs under control and support healthier profit margins.

What practical strategies can reduce DTF costs without sacrificing quality?

Adopt a scalable setup, buy materials in bulk, batch similar designs to reduce setup time, optimize designs to reduce color changes, maintain and service equipment regularly, and compare suppliers to secure volume discounts. These steps reduce DTF costs and improve throughput, helping maintain quality while lowering per-shirt expenses.

How do I estimate DTF costs per shirt and set competitive prices for my products?

Use a fixed-vs-variable cost framework. Cost per shirt = (Equipment depreciation per month) + (Overhead per month) + (Labor per shirt) + (Consumables per shirt) + (Energy per shirt). For example, with 600 shirts/month and depreciation $300, overhead $150, consumables $0.60/shirt, energy $0.25/shirt, and labor $0.50/shirt, the cost per shirt is $2.10. Once you have this, set a price that covers these costs plus your target profit margin, while remaining competitive in your market.

| Key Topic | Summary |

|---|---|

| Introduction | DTF costs are a major consideration for starting or scaling a direct-to-film (DTF) printing operation; they go beyond printer price and inform budgeting, equipment choices, and competitive product pricing. |

| What drives DTF costs? | DTF costs include more than the sticker price; key categories are equipment investment, materials/consumables, ongoing operating costs, labor/time, and overhead/depreciation. |

| Equipment investment | Printer capable of CMYK plus white, a heat press, and starter kits; typical prices range from a few thousand up to $6k–$8k for mid-range machines; heat presses often cost $800–$2,000. Other startup costs: software, ventilation, and starter bundles. |

| Materials and consumables | DTF films/transfer sheets, inks (white essential), adhesive powder, curing/finishing supplies, and maintenance items. Costs vary with volume, colors, and fabric; budget by estimating consumables per shirt and scaling with production. |

| Operating costs & maintenance | Electricity, water, maintenance; ink refills, head-cleaning cycles, and calibration. Allocate a monthly maintenance budget (a few hundred dollars in year one) to keep systems reliable. |

| Labor and time | Operator time for design, RIP, printing, powdering, curing, and finishing. Batch processing and clear workflows reduce cost per shirt. |

| Overhead & depreciation | Rent, utilities, insurance, software licenses, and depreciation of equipment. Include these in cost-per-shirt calculations, especially for multi-year planning. |

| Estimating cost per shirt | Split costs into fixed and variable components. Cost per shirt = equipment depreciation per month + overhead per month + labor per shirt + consumables per shirt + energy per shirt. Example demonstrates practical budgeting. |

| Budgeting strategies | Start scalable, buy materials in bulk, optimize designs/color usage, batch print/press, prioritize reliable consumables, maintain equipment, and negotiate with suppliers. |

| DTF costs vs other methods | DTF has different cost profiles than DTG and heat transfer. Evaluate total cost of ownership across methods to determine the best fit for your product mix. |

| Starting lineup costs | Phase 1: Basic setup for 200–300 shirts; Phase 2: Expand with a second line; Phase 3: Consider automation if margins allow; decisions should be based on real-world data. |

Summary

DTF costs shape every decision in starting or growing a direct-to-film printing operation, influencing equipment choices, workflows, and pricing strategies. A thoughtful budgeting approach separates fixed and variable costs, accounts for depreciation, materials, labor, and overhead, and uses real production data to set competitive prices while protecting margins. By focusing on scalable systems, reliable consumables, batch processing, and smart supplier negotiations, you can manage DTF costs effectively while delivering high-quality garments and driving sustainable business growth.