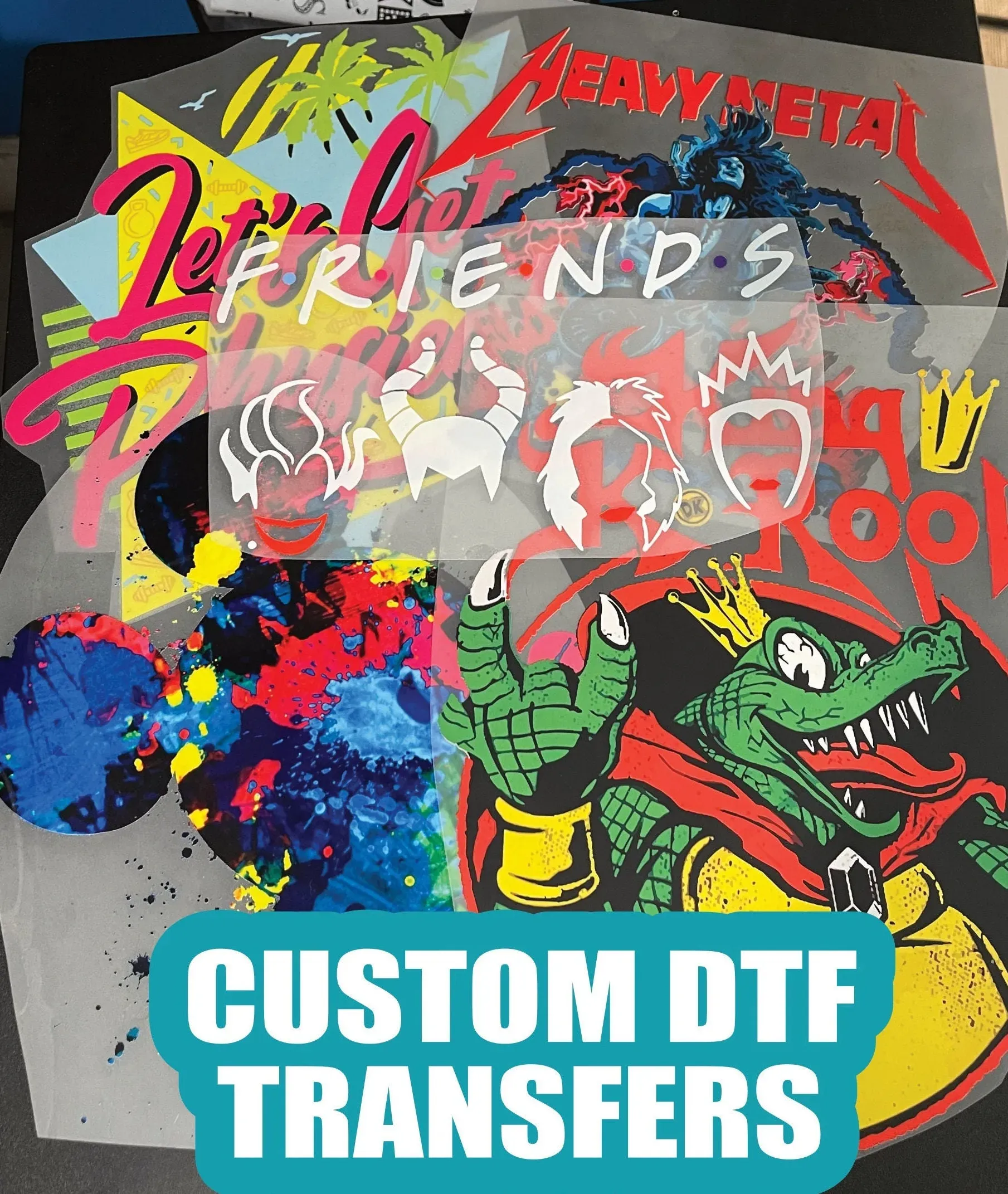

DTF transfers, or Direct to Film transfers, have emerged as a game-changing technique for custom fabric printing enthusiasts. This innovative printing method allows creators of all levels to bring their designs to life with vibrant colors and impressive detail. The DTF printing process involves a straightforward approach, utilizing specialized film and heat press transfer technology to easily apply intricate graphics onto various fabrics. Whether you’re a DIY novice or an experienced crafter, DTF transfers provide an exciting way to explore your creativity while producing professional-quality prints. In this guide, we’ll delve into the essentials of DTF transfers and how they can elevate your custom fabric printing projects.

When it comes to applying designs onto fabric, DTF transfers, also known as Direct to Film transfers, are one of the most versatile options available today. This technique combines the ease of heat transfer with the quality of modern printing, making it ideal for personal and commercial projects alike. This method of custom fabric application is designed specifically for those who enjoy hands-on creation, allowing users to harness their artistic flair through DIY DTF transfer processes. With the right equipment and a bit of practice, anyone can master this printing technique and produce stunning results that stand the test of time. Join us as we explore the intricacies of DTF transfers and unlock your potential in the world of fabric printing.

Understanding Direct to Film Printing

Direct to Film (DTF) printing stands at the forefront of modern fabric printing technologies. This method involves a unique process where designs are transferred onto a special film that retains intricate details and vibrant colors. By utilizing advanced printers that cater specifically to DTF techniques, crafters can achieve stunning results on a variety of fabrics. Furthermore, the flexibility of DTF enables users to print on fabrics ranging from cotton to polyester, enhancing the versatility of the applications.

The appeal of DTF printing lies not only in its visual output but also in its ease of use. Unlike traditional printing methods that require numerous steps and extensive setups, DTF simplifies the workflow. With just a few essential tools—such as a DTF printer, film, and a heat press—anyone can dive into creating custom designs with minimal challenges. As a result, this method has garnered a dedicated following among DIY enthusiasts looking for simplicity without sacrificing quality.

The DTF Printing Process Explained

The DTF printing process is an innovative technique that combines technology and creativity seamlessly. It begins with designing an image using graphic design software, which is then printed onto a specially coated film. Once the ink is applied, a hot-melt adhesive powder is sprinkled on the wet ink to ensure a robust bond during the heat transfer. This step is critical as it sets the stage for vibrant and durable prints that can withstand multiple washes, making them suitable for everyday wear.

After the ink and powder have been applied, the film is cured with heat, adhering the design to the material. This heat press step is essential, as it transfers the image onto the fabric, resulting in a professional finish. The combination of high-quality inks and specialized equipment available today has made the DTF printing process not just efficient, but also capable of producing complex designs with ease. DIYers can achieve high-quality results without the steep learning curve associated with more traditional printing methods.

Equipment Essentials for DTF Transfers

To embark on your DTF printing adventure, specific equipment is necessary to ensure quality and efficiency. At the core of your setup is a DTF printer, designed to handle specialty inks that provide durability and brightness in the final output. Coupled with DTF transfer films, which are made to withstand the high temperatures of heat pressing, these components work together to create stunning designs on various fabric types.

Additionally, having a reliable heat press machine is indispensable in the DTF transfer process. This equipment applies the necessary heat and pressure required to adhere the inked film onto the fabric effectively. Investing in quality graphic design software, such as Adobe Illustrator or CorelDRAW, can also elevate your projects, allowing for professional-grade designs tailored to your specific needs. With the right tools, DIY enthusiasts can enhance their crafting experience and produce high-quality custom fabric prints.

Advantages of Using DTF Transfers for Custom Fabric Printing

One of the primary advantages of DTF transfers is the incredible versatility they offer. Unlike other printing methods that might be limited to specific materials, DTF allows for printing on various fabrics, including cotton, polyester, and even blends. This flexibility empowers DIY enthusiasts to experiment with different projects across multiple platforms, whether clothing, home décor, or accessories.

Moreover, DTF printing is remarkably user-friendly. Many beginners find the process less daunting than traditional printing techniques, which often require extensive setup and hands-on knowledge. With straightforward steps, such as printing, applying adhesive, and heat pressing, even novices can quickly produce high-quality custom prints. This accessibility makes DTF an appealing option for crafters of all skill levels looking to enhance their creative output.

Navigating Challenges in DTF Transfer Printing

While DTF transfers provide numerous benefits, they also come with their set of challenges. One common issue DIY enthusiasts face is sourcing quality consumables such as inks and transfer films. The market is saturated with options that vary significantly in quality, making it essential for crafters to do their research and select reliable suppliers to ensure optimal results in their printing projects.

Additionally, mastering the printer settings and transfer techniques can demand a learning curve. New users may find it challenging to achieve consistent outcomes initially, which can be disheartening. However, with practice, perseverance and active participation in online communities, users can overcome these obstacles, harnessing the full potential of DTF printing to express their creativity without limits.

Joining the DTF Community and Resources

The DTF printing community is vibrant and supportive, providing an extensive range of resources for enthusiasts. Online forums, tutorials, and social media groups offer spaces for users to share tips, showcase their projects, and troubleshoot common problems. Engaging with these platforms not only helps in improving one’s skills but also keeps users updated on the latest trends and innovations within the DTF realm.

For those new to DTF printing, exploring these resources can significantly aid in the learning process. From step-by-step guides on the DTF printing process to tips on selecting the best materials, the wealth of knowledge shared by seasoned printers can inspire and guide newcomers. By immersing themselves in this community, DIYers can enhance their creative experience and enjoy the camaraderie that comes with this exciting craft.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, are a printing method used to apply custom designs onto fabric. The process involves printing a design onto a special film coated with adhesive which, after being heat-pressed onto the fabric, results in high-quality, vibrant graphics that adhere well to various materials.

What equipment do I need to get started with DTF printing?

To begin with DTF printing, you’ll need a DTF printer, DTF transfer film, hot-melt powder, a heat press machine, and graphic design software. Investing in quality equipment is crucial for achieving optimal results and a smooth DIY DTF transfer experience.

Can I use DTF transfers on any type of fabric?

Yes, DTF transfers are versatile and can be applied to a wide range of fabrics, including cotton, polyester, and blends. This adaptability makes DTF printing an excellent choice for various DIY projects such as T-shirts, hoodies, and more.

What are the advantages of using DTF printing for custom fabric printing?

DTF printing offers several advantages, including versatility on different materials, ease of use for beginners, cost-effectiveness with minimal waste, and high-quality results that remain vibrant after multiple washes, making it ideal for DIYers.

What challenges might I face when using DTF transfers?

Common challenges with DTF transfers include sourcing quality consumables like films and inks and mastering the printer settings. However, with practice and engaging with online communities for support, these challenges can be successfully managed.

Where can I find resources and support for DTF printing?

There are countless online resources for DTF printing enthusiasts, including tutorials, forums, and YouTube channels. Engaging with social media communities is a great way to share experiences and learn best practices from fellow DIY DTF transfer creators.

| Key Points | Details |

|---|---|

| What is DTF Transfer? | Direct to Film (DTF) transfers allow custom designs to be printed on fabric using a special film and heat press. |

| Recent Developments | In 2024, new printers and enhanced ink formulas have improved efficiency and product quality for DIY enthusiasts. |

| Equipment Needed | DTF Printer, DTF Transfer Film, Hot-Melt Powder, Heat Press Machine, Graphic Design Software (e.g. Adobe Illustrator). |

| Advantages | Versatility, ease of use, cost-effectiveness, high-quality results. |

| Challenges | Sourcing quality consumables and mastering printer settings can take time and practice. |

| Community Resources | Online tutorials, forums, and social media groups support DIY enthusiasts to navigate DTF printing. |

Summary

DTF transfers offer an exciting and accessible method for DIY enthusiasts to create custom designs on fabric. Through the use of specialized printers and adhesives, this innovative process allows creators of all skill levels to explore their artistic potential. As advancements in DTF technology continue, more resources and tools become available, enabling individuals to produce vibrant, lasting designs that can stand up to wear and washing. With the right equipment and a supportive community, anyone can jump into the world of DTF transfers and unleash their creative talents.