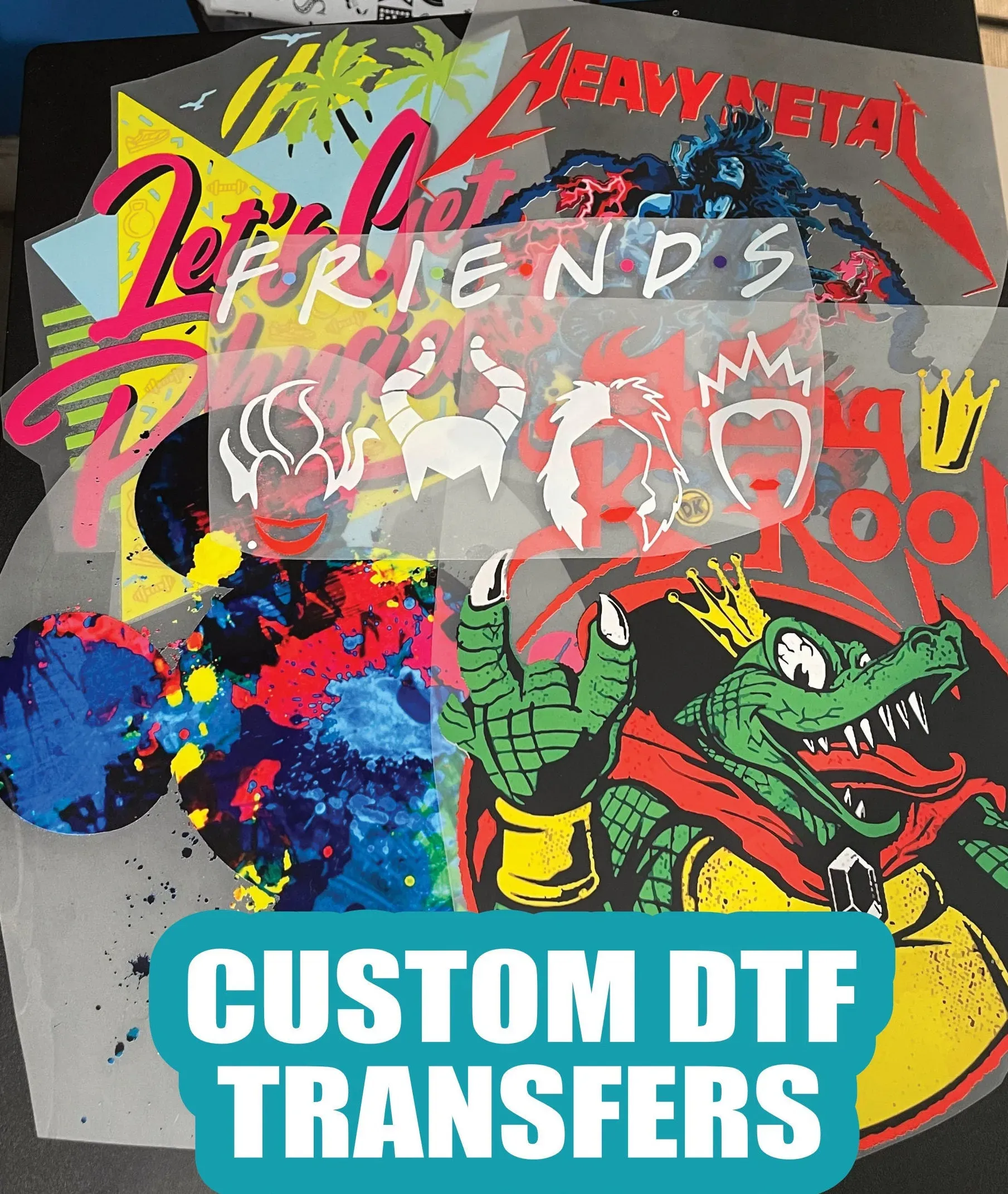

If you’re considering diving into the world of custom apparel, DTF transfers, or Direct-to-Film transfers, are an excellent way to start. This captivating printing method allows for vibrant, high-quality designs to be printed directly onto a range of fabrics, offering an edge for both hobbyists and aspiring business owners. In this guide, we’ll unpack everything you need to know about DTF printing for beginners, from the essential equipment required to the numerous benefits this technique presents. Whether you’re intrigued by the variety of colors or the possibility of low-cost small runs, DTF transfers offer a multitude of options for creating unique apparel. So, if you’re eager to learn how to use DTF transfers effectively, stay tuned as we explore this exciting trend in custom apparel printing!

Exploring the art of custom garment creation often leads enthusiasts to innovative techniques like transfer printing—a versatile approach that includes methods such as DTF or Direct-to-Film printing. This form of digital apparel decoration utilizes specialized films to enable stunning graphics on various clothing items. For those keen on starting a small business or simply seeking a new pastime, the process of utilizing these transfers has grown in popularity due to its ease of use and remarkable results. By familiarizing yourself with custom film transfers, you’ll unlock the potential for designing vibrant textiles that stand out in any wardrobe. Join us as we delve deeper into the fundamentals of DTF printing and uncover its many advantages.

Understanding DTF Transfers: A Complete Overview

DTF transfers, or Direct-to-Film printing, are revolutionizing the custom garment industry, bringing forth a new era of vibrant, high-quality designs. This innovative printing method combines the flexibility of digital printing with the durability needed for apparel, making it attractive to both hobbyists and professional printers. The process begins by printing a design onto a specialized film using a modified inkjet printer, followed by the application of hot-melt adhesive powder. After applying heat, the design firmly adheres to the fabric, providing a seamless finish that can withstand multiple washes without fading.

For beginners, understanding DTF transfers involves learning not just the process but also the equipment and materials required. This includes a suitable DTF printer, transfer film, hot-melt powder, and a heat press to apply consistent heat and pressure. Each component plays a crucial role in achieving optimal results and can significantly impact the quality of the final product. With this foundational knowledge, newcomers will be well-prepared to explore more complex aspects of custom apparel printing.

The Equipment Essentials for DTF Printing Success

Investing in the right equipment is critical for success in DTF printing. A specialized DTF printer is at the forefront of your operation; these printers are designed to work with DTF inks and require less modification compared to traditional inkjet printers. Selecting a printer from reputable brands ensures better quality prints and reliable performance. Additionally, using high-quality transfer film is paramount; films designed specifically for DTF will provide the best compatibility and results, ensuring that the prints adhere effectively to various fabric types.

Moreover, a heat press is essential to achieving a consistent and durable transfer. Unlike home irons, heat presses can apply the necessary heat and pressure uniformly across the design, significantly increasing durability and finish quality. Completing your toolbox with adequate design software enables you to create tailor-made designs that cater to your target market, enhancing your custom apparel business’s appeal. By prioritizing these essentials, you create a strong foundation for your DTF printing business.

Benefits of DTF Printing: Why It’s Ideal for Beginners

One of the primary benefits of DTF printing is its versatility. This method enables you to print on a wide range of fabrics, including cotton, polyester, and blends, catering to diverse customer preferences. This flexibility allows beginners to experiment with various materials and styles, leading to unique and personalized garments. Additionally, DTF printing produces vibrant colors and soft finishes, ensuring that the end products not only look professional but also feel great to wear.

Another significant advantage is that DTF printing is cost-effective, especially for small runs. Unlike traditional screen printing that requires extensive setup for single designs, DTF transfers can easily accommodate low-volume orders. This is particularly beneficial for startups or hobbyists looking to test their designs in the market without excessive upfront costs. By focusing on the immediate benefits of DTF printing, beginners can quickly establish their place in the custom apparel sector while minimizing financial risks.

Overcoming Beginner Challenges with DTF Transfers

As with any new venture, beginners may encounter several challenges while mastering DTF transfers. One common hurdle is understanding the intricacies of the process, including machine setup and operation. It’s crucial for new users to familiarize themselves with their printer’s specifications and the materials they are working with, as missteps can lead to disappointing results. Taking time to watch tutorials and read guides can significantly ease the learning curve and build confidence.

Financial concerns can also weigh heavily on beginners. While the initial investment in quality DTF equipment might seem daunting, recognizing it as a long-term investment can help ease this anxiety. Many newcomers find that as they gain experience and attract customers, the initial costs become justified by the profits generated. Moreover, joining online communities can provide support, advice, and shared experiences that can help newcomers iron out the new kinks in their DTF printing journey.

Navigating Resources for Learning DTF Printing

A critical step for beginners embarking on DTF printing is to utilize the many resources available for education. Online tutorials and courses provide structured learning paths that address everything from the basics of DTF printing to advanced design techniques. Websites like Printful Academy offer valuable guides and step-by-step instructions for those wishing to enhance their skills in this captivating printing method.

In addition to formal courses, social media platforms and forums such as Facebook groups and Reddit communities allow beginners to share their experiences, ask questions, and seek feedback on their designs. Engaging with other DTF printing enthusiasts creates a sense of community, encouraging collaboration and support as novices navigate the fascinating world of custom apparel printing.

Future Trends in DTF Printing and Custom Apparel

The custom apparel market is rapidly evolving, with DTF printing taking center stage due to its efficiency and quality. As personalization becomes a growing demand among consumers, businesses that embrace DTF technology can quickly adapt to meet these needs. Trends indicate that demand for custom printing will continue to rise as consumers seek unique designs that resonate with their personal styles, making now an excellent time for beginners to step into this market.

As advancements in DTF printing technology continue to emerge, we can expect to see improvements in print quality, speed, and user-friendliness. Innovations in ink formulation, transfer techniques, and integration with design software are all contributing factors that will ensure DTF printing remains a vibrant option in the custom apparel sector. For beginners, staying informed about these trends will not only enhance their current capabilities but also position them favorably for future opportunities in this dynamic industry.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a printing method where designs are printed onto a special film. The printed film is coated with a hot-melt adhesive powder that fuses the design to the fabric when heat is applied. This technique allows for vibrant and high-quality custom apparel printing on various materials.

What equipment do I need for DTF printing?

To start DTF printing, you’ll need a DTF printer capable of using DTF inks, DTF transfer film, hot-melt adhesive powder, a heat press, and graphic design software. These tools will help you print and apply your designs effectively for custom apparel.

What are the benefits of using DTF transfers for custom apparel printing?

The benefits of DTF transfers include versatility with fabric choices, high-quality and durable prints, and cost-effectiveness for small runs. DTF printing can be applied to different materials and produces vibrant colors that withstand multiple washes, making it ideal for custom apparel.

How do I get started with DTF transfers as a beginner?

To start with DTF transfers, familiarize yourself with the necessary equipment, gather your supplies, and utilize online resources like tutorials and social media groups. Practicing with design creation and DTF printing techniques will also aid in overcoming common beginner challenges.

What common challenges do beginners face when using DTF transfers?

Beginners often encounter challenges like understanding the DTF printing process, managing costs for initial equipment investments, and creating designs that print well. Taking time to learn about the equipment and design requirements will help alleviate these challenges.

Where can I find resources and support for learning DTF printing?

There are numerous resources available for learning DTF printing, including online tutorials, YouTube channels focused on DTF techniques, and community groups on platforms like Facebook and Reddit. Engaging with these resources can provide valuable insights and support as you learn.

| Aspect | Details |

|---|---|

| What are DTF Transfers? | A method of printing designs onto a special film that is then transferred to fabric using a hot-melt adhesive. |

| Key Benefits | Versatility, high quality, durability, and cost-effectiveness for small runs. |

| Equipment Needed | DTF printer, transfer film, hot-melt powder, heat press, and design software. |

| Learning Resources | Online tutorials, YouTube channels, and social media groups focused on DTF printing. |

| Common Challenges | Understanding the printing process, cost considerations, and design management. |

| Market Trends | Growing popularity due to personalization and quick turnaround times for small orders. |

Summary

DTF transfers are an innovative method for custom printing that opens doors for beginners looking to enter the apparel industry. By utilizing direct-to-film technology, individuals can create stunning, durable designs across a wide range of fabrics. With essential equipment and resources readily available, anyone can embark on the journey of DTF transfers and transform their creative ideas into reality. The flexibility and cost-effectiveness of this printing method not only meet the demands of hobbyists but also support small businesses aiming for quality and efficiency in their production process. As trends indicate a rise in customization, now is an ideal time to explore what DTF transfers can offer.