In the ever-evolving landscape of custom apparel printing, DTF transfers, or Direct-to-Film transfers, stand out as a revolutionary technique that delivers vibrant and durable prints onto fabrics. If you’re keen to explore the world of DTF printing for beginners, this guide is tailored just for you, combining essential steps and practical tips to harness the benefits of DTF transfers effectively. This process not only simplifies the creation of high-quality designs but also opens up creative avenues for personalized clothing. By mastering the DTF transfer process, you’ll be equipped to produce stunning apparel that resonates with your unique style. Let’s dive into the exciting realm of DTF transfers and discover how to elevate your custom printing projects to new heights!

When it comes to creating stunning designs for clothing, one cannot overlook the advantages offered by the process of Direct-to-Film transfers. This cutting-edge method, often referred to as DTF printing, harnesses specialized films to ensure your graphics are not just eye-catching but also resilient. For those exploring how to use DTF transfers, this technique is increasingly favored due to its ease of application and versatile nature across different materials. By understanding the key benefits of DTF transfers, you’ll find ways to enhance your custom apparel creations, achieving professional-quality results with relative simplicity. Join us as we delve into the specifics of this innovative printing method and its many applications!

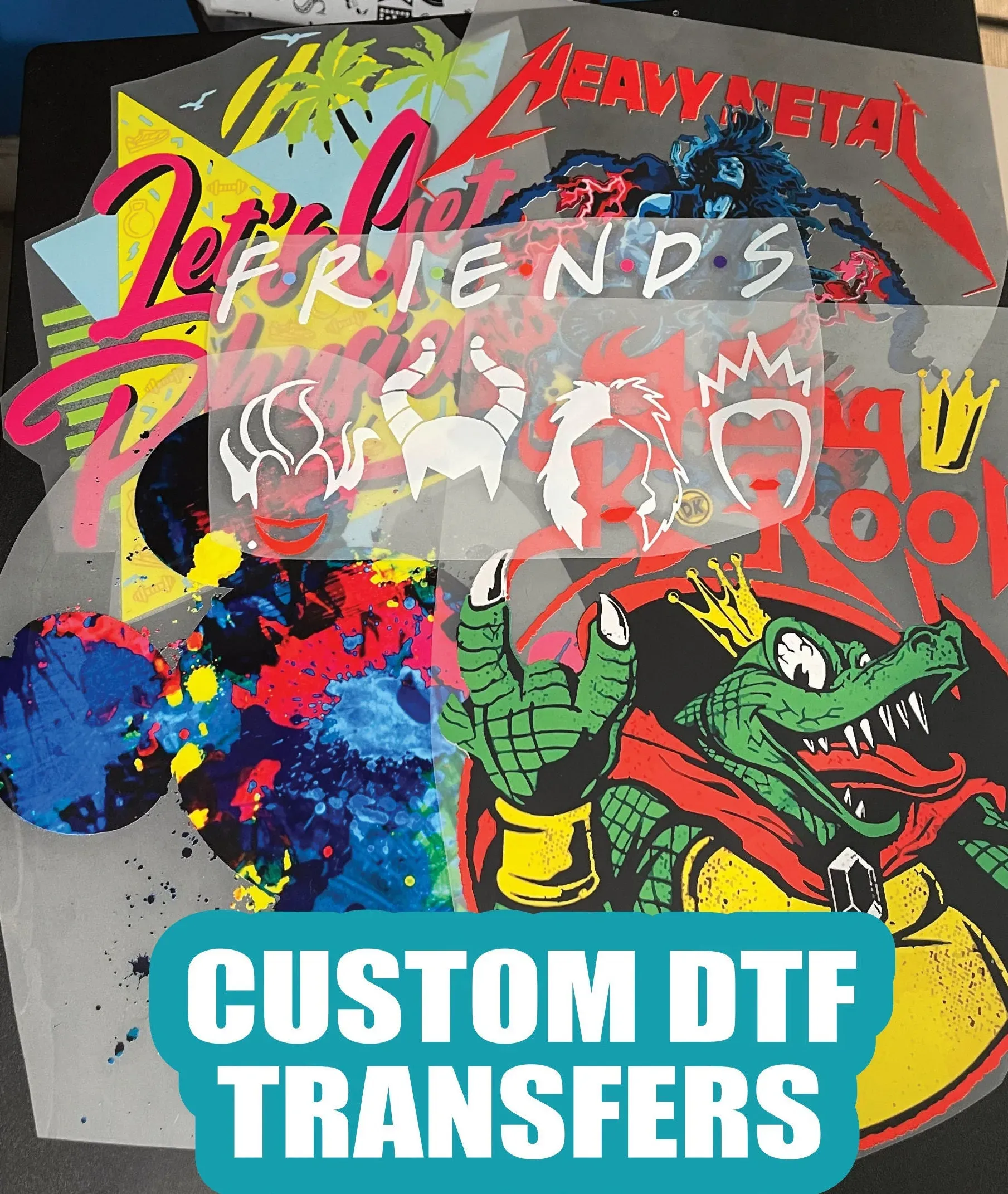

Understanding the Benefits of DTF Transfers for Custom Apparel Printing

DTF transfers offer numerous benefits that make them an ideal choice for custom apparel printing. First, the vibrant, full-color images produced through this method are not just visually appealing but also have the robustness to withstand multiple washes without fading. This quality is particularly important for businesses and designers looking to produce durable merchandise for their customers. Moreover, DTF transfers can be applied to a wide range of fabrics, including cotton, polyester, and blends, giving users the flexibility to expand their product offerings.

In addition to their durability, DTF transfers provide excellent detailing which is crucial for designs with intricate patterns or gradients. The technology allows for incredibly fine details that can accurately represent the original artwork, ensuring that customers receive products that meet or exceed their expectations. Another significant benefit is the ease of application—DTF transfers can be pressed on with a heat press, making the process accessible and relatively simple for beginners and experienced printers alike.

Step-by-Step Guide to the DTF Transfer Process

Mastering the DTF transfer process requires understanding each step from the initial design to the final application. Initially, designers should focus on creating high-quality graphics using design software. Utilizing CMYK color modes ensures that prints will come out accurately and vibrantly. Once the image is prepared, it is printed onto the DTF film using a dedicated DTF printer, equipped with compatible inks that contribute to optimal results.

After printing, the application of hot melt adhesive is crucial. This involves evenly sprinkling the adhesive powder over the wet ink and removing any excess to ensure a smooth application. The curing process—where appropriate heat is applied to bond the adhesive to the ink—cannot be neglected, as it directly affects the quality and durability of the transfer. Finally, precise placement on the fabric using the correct heat press settings helps solidify the transfer, making it a reliable and effective process for creating custom apparel.

Essential Materials for Successful DTF Printing

To achieve quality results in DTF printing, certain materials are essential. The first key component is a dedicated DTF printer. This specialized equipment utilizes high-quality inks optimized for transferring onto films which, in turn, are applied to fabric. Without the right printer, it’s nearly impossible to create the vivid and durable images that DTF printing is known for.

Secondly, the choice of DTF transfer films hugely impacts the overall success of your projects. High-quality films ensure the ink adheres well and results in a vibrant finish. Furthermore, investing in quality hot melt adhesive powder can make a significant difference in the durability and appearance of the final product. A reliable heat press is also indispensable, as it determines how effectively the transfers are applied to various materials.

Mastering the Art of Design Creation for DTF Printing

Creating designs suitable for DTF printing requires some specific considerations compared to other methods. The resolution of the designs is critical; it’s best to start with a resolution of at least 300 DPI to ensure that your printed images are sharp and clear. Furthermore, understanding color modes, specifically CMYK, is fundamental because colors printed using this method can differ from those displayed on screens, which typically use RGB.

Additionally, incorporating layers and fine details in your designs can enhance the visual appeal of the final product. As DTF printing allows for intricate designs, artists should also experiment with various elements like gradients, shadows, and textures that can significantly improve the overall impact. Testing designs on smaller scales can help beginners refine their skills before transitioning to larger projects.

Eco-Friendly Advancements in DTF Transfers

The printing industry is continuously evolving, and one significant advancement is the shift toward eco-friendly practices within DTF printing. Many manufacturers are now producing hot melt powders that are not only effective but also environmentally friendly. This change minimizes the ecological footprint of custom printing while still delivering high-quality results.

Additionally, innovations in DTF transfer films are leading to alternatives that are recyclable and less harmful to the environment. These advancements illustrate the industry’s commitment to sustainability, providing enthusiasts and business owners ways to print responsibly while still meeting growing consumer demands for quality and durability.

Resources for Beginners in DTF Printing

For those new to DTF printing, a wealth of resources is available to help you build your skills and confidence. Numerous online tutorials and workshops can be accessed through platforms like YouTube, where experienced printers share their techniques and tips. Channels dedicated to detailed printing tutorials offer step-by-step guidance through the DTF process, ensuring newcomers are well-informed.

Additionally, blogs and articles from professional printing experts can offer valuable insights. Platforms like Printful and Avery provide information on best practices, troubleshooting common issues, and understanding the nuances of DTF transfers. Engaging with these resources enables beginners to learn from others’ experiences and develop a solid foundation in custom apparel printing.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a method of custom apparel printing where images are printed onto a film using a specialized DTF printer. The wet ink is coated with hot melt adhesive powder, which allows for vibrant and durable designs to be transferred onto various fabrics using heat.

What materials do I need for DTF printing?

To get started with DTF printing, you need a dedicated DTF printer, high-quality DTF transfer films, hot melt adhesive powder, and a reliable heat press machine. These materials are essential for achieving high-quality prints and ensuring good adhesion to garments.

What are the benefits of using DTF transfers for custom apparel?

DTF transfers offer several benefits for custom apparel printing, including vibrant color reproduction, the ability to print on a variety of fabrics, and ease of application. Additionally, DTF transfers are known for their durability and wash resistance, making them ideal for long-lasting designs.

How can beginners learn to use DTF transfers effectively?

Beginners can effectively learn to use DTF transfers by following step-by-step guides that cover the DTF transfer process, required materials, and application tips. Online resources like tutorials on YouTube and articles from reputable printing blogs can also provide valuable insights and practical skills.

What is the DTF transfer process step-by-step?

The DTF transfer process involves printing an image onto specialized film, applying adhesive powder to the wet ink, curing the design with heat, and then transferring it to the fabric using a heat press. Following precise temperature, pressure, and time settings is crucial for a successful transfer.

Are there any recent advancements in DTF transfers to be aware of?

Yes, recent advancements in DTF transfers include new material innovations that allow printing on diverse fabrics such as nylon, eco-friendly hot melt powders that reduce environmental impact, and user-friendly DTF printers that simplify setup for beginners, making the process more accessible.

| Step | Description | Key Points |

|---|---|---|

| Step 1: Process Understanding | Learn about the Direct-to-Film printing process. | Essential for vibrant images and effective adhesion. |

| Step 2: Required Materials | Gather essential materials like a DTF printer, film, adhesive powder, and heat press. | Quality materials ensure better transfer results. |

| Step 3: Preparation and Printing | Create a design and set up the printer for high-quality outputs. | Use CMYK color mode for accurate colors. |

| Step 4: Applying Hot Melt Powder | Sprinkle adhesive powder evenly over the printed design. | Even application is crucial for quality. |

| Step 5: Curing the Print | Cure the design with heat to melt the adhesive. | Proper curing is key for a lasting transfer. |

| Step 6: Transferring to Fabric | Position the film on the fabric and use the heat press to adhere it. | Correct settings are essential for success. |

| Step 7: Cooling and Peeling | Allow cooling before peeling the film away to reveal the design. | Carefulness in peeling ensures the design adheres well. |

Summary

DTF Transfers represent a revolutionary method in custom apparel production, enabling users to create high-quality designs with ease. By mastering the step-by-step process outlined in this guide, beginners are equipped with the tools and knowledge necessary to excel in this printing technique. From understanding the essential materials to applying innovative techniques, the advancements in DTF Transfers are making it easier than ever for enthusiasts and aspiring entrepreneurs to bring their creative visions to life. As technology evolves, so do the possibilities with DTF printing, ensuring that anyone, regardless of experience, can achieve professional results.