DTF transfers have rapidly gained popularity in the printing world, offering vibrant and durable solutions for custom garments. However, those new to Direct to Film printing often fall victim to common mistakes that can severely impact the quality of their final product. Issues ranging from wrong material DTF transfers to inadequate garment preparation can lead to disappointing results. This article will guide you through the top five pitfalls to avoid while working with DTF transfers, empowering you with the knowledge needed for exceptional print outcomes. By understanding these key areas, you can ensure your printed designs not only look great but stand the test of time.

In the realm of custom printing, Direct to Film (DTF) transfer technology is redefining how designs are applied to fabric. Known for its ability to produce stunning visuals with impressive durability, this method requires careful attention to detail to achieve the best results. Many creators and businesses, however, encounter challenges such as inadequate preparation or improper material choices that can compromise print quality. It’s essential to familiarize yourself with the nuances of this innovative technique, including effective quality control measures and optimal printer settings. By enhancing your understanding and application of DTF transfers, you can elevate your printing projects to new heights.

Top DTF Printing Mistakes and How to Avoid Them

In any specialized field, recognizing and addressing common mistakes can significantly alter outcomes, and DTF printing is no exception. Some of the most frequent errors encompass material selection, garment preparation, and printer settings. These missteps can adversely affect the final product, leading to prints that don’t adhere properly or lack vibrancy. By thoroughly understanding these pitfalls, both novices and veterans in DTF printing can take proactive measures to elevate their work.

Primarily, one of the gravest errors is underestimating the quality of materials used for DTF transfers. Utilizing subpar films or inks can result in lackluster prints that do not meet customer expectations. It’s essential to invest in top-tier materials specifically designed for DTF printing. With a proper understanding and assessment of available options, printers can greatly improve their final products.

The Impact of Wrong Material Selection in DTF Transfers

Selecting the right materials for DTF printing is pivotal. Many beginners often overlook this step, mistakenly believing that any film will suffice for their projects. In reality, the film type and quality can significantly influence the adhesion and clarity of the final print. Low-quality films may not adhere well, resulting in peeling and poor longevity, which can frustrate both the printer and their clients.

To avoid issues, it’s vital to conduct thorough research on compatible materials for your specific printing process. Ensure that the film you choose matches the type of ink you’re employing and is suited to the fabric you’ll be printing on. This careful consideration can enhance your DTF transfer quality, resulting in vibrant, durable prints that stand out.

Maximizing Garment Preparation for DTF Transfers

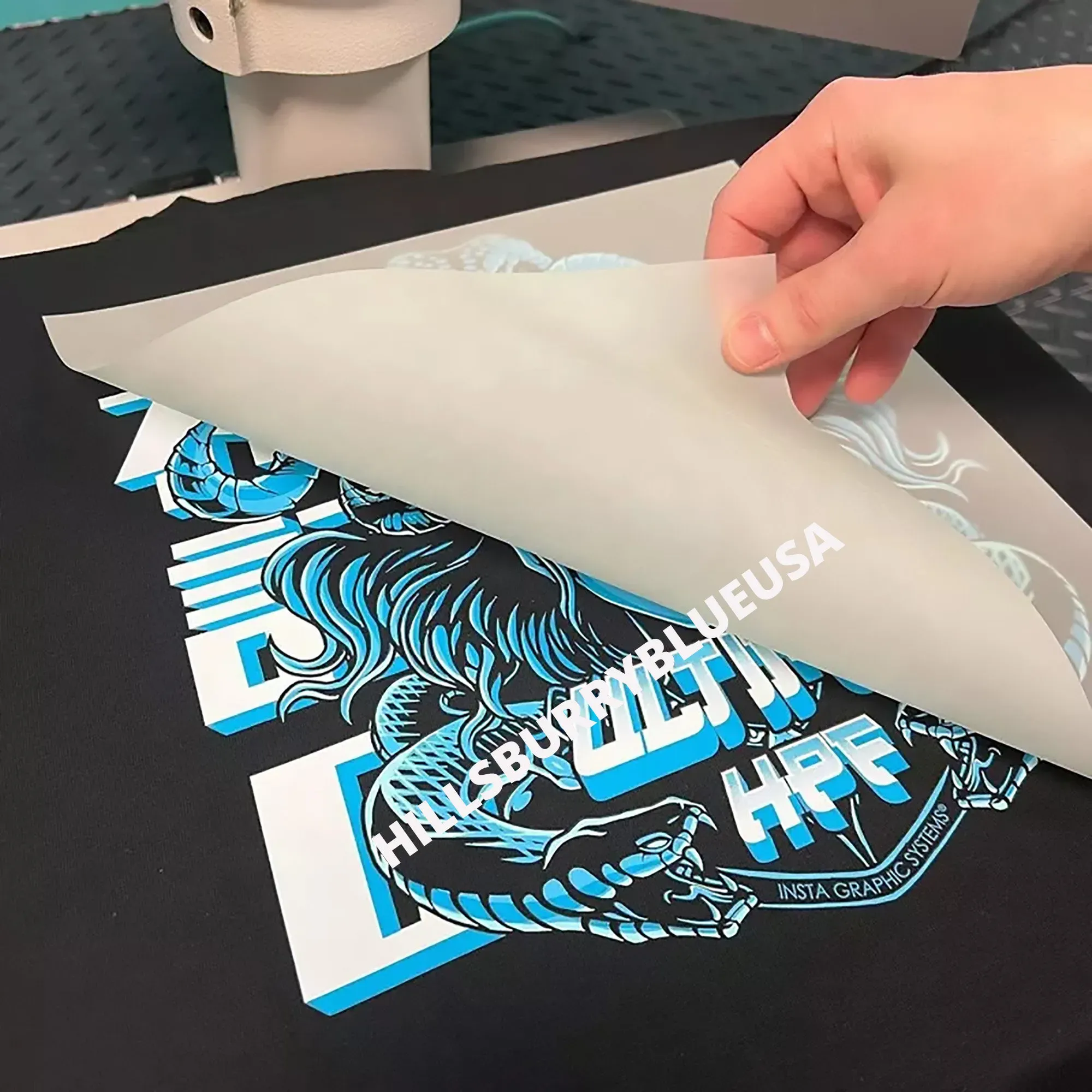

Adequate preparation of the garment is an essential step in the DTF transfer process that cannot be overlooked. The cleaning and pre-treatment stages set the foundation for successful adhesion and longevity of prints. Fabrics that aren’t prepped properly can harbor oils, dirt, and other contaminants, leading to poor transfer results. This can be extremely frustrating for both the printer and the customer, ultimately undermining the quality of the final product.

Pre-washing garments and choosing the right pre-treatment methods are crucial to enhance the adhesive strength of the DTF transfer. Investing time in preparing the fabric ensures that the final design sits well and maintains its integrity long after application. Referencing industry best practices can provide valuable insights into effective garment prep techniques.

Essential Printer Settings for Perfect DTF Transfers

Opting for incorrect printer settings is a classic mistake when diving into DTF printing. The printer’s calibration is fundamental in determining how accurately the print will reflect the intended design. Misaligned or poorly calibrated printer settings can lead to warped images and inaccurate color displays on the substrate.

Therefore, before every printing job, it’s necessary to review and adjust printer settings based on the specific film and ink being used. Many experienced printers recommend specific profiles that optimize performance for various materials, ensuring that the finished prints meet high standards.

The Importance of Proper Curing in DTF Transfers

Curing is a vital aspect of the DTF process that directly influences the durability and quality of the print. Neglecting the curing stage can lead to undesirable outcomes such as fading or cracking in the print, drastically reducing the lifespan of the garment. Often, beginners may overlook proper curing times, thinking that a quick fix will suffice, but this can be detrimental.

Following curing instructions laid out by manufacturers can enhance the prints’ resistance to wear and wash cycles. Understanding the specific curing needs for each transfer ensures that designs remain bright and intact throughout the life of the garment. Continuous education on this step can help maintain the quality of DTF products.

Quality Control Steps to Enhance DTF Transfer Outcomes

Implementing effective quality control measures is crucial in avoiding errors during the DTF printing process. By neglecting this step, businesses risk dispatching products that do not meet quality standards, which can damage brand reputation and lead to customer dissatisfaction. A structured quality control process allows printers to assess alignment, adhesion, and overall aesthetics before fulfilling orders.

Regular checks at different stages of production can capture issues early, ensuring that every item delivered reflects the brand’s commitment to excellence. Establishing an efficient quality control protocol not only improves product outcomes but fosters trust between the brand and its customers.

Frequently Asked Questions

What are some common DTF printing mistakes to avoid?

When working with DTF transfers, common mistakes include selecting the wrong material, inadequately preparing the garment, improper printer settings, overlooking the curing process, and skipping quality control steps. Avoiding these pitfalls can enhance the quality and durability of your prints.

How can I ensure the highest quality in my DTF transfers?

To achieve the best results with DTF transfers, focus on using high-quality transfer materials, ensuring proper garment preparation, calibrating printer settings correctly, following curing instructions meticulously, and implementing a thorough quality control process.

What materials should I use for DTF transfers?

For optimal DTF printing, choose high-quality transfer films that are compatible with your printer and inks. Using reputable brands known for their reliability in DTF applications will significantly improve adhesion and print quality.

Why is garment preparation crucial for DTF printing?

Proper garment preparation is essential for DTF transfers because contaminants like dirt and oil can prevent the transfer from adhering properly. Pre-treating and cleaning the fabric ensures better adhesion and enhances the longevity of the print.

What printer settings should I use for Direct to Film printing?

Setting your printer correctly is critical for successful DTF transfers. Verify that your printer settings align with the specifications of the DTF film, adjusting as needed to ensure optimal color output and alignment during printing.

How important is the curing process for DTF transfers?

The curing process is vital for DTF transfers because it seals the design onto the fabric. Proper curing prevents fading and cracking, ensuring that your prints remain vibrant and durable over time. Always adhere to the recommended curing temperatures and times.

| Mistake | Description | Recommendation |

|---|---|---|

| Neglecting Proper Material Selection | Choosing inappropriate transfer materials which can lead to poor adhesion and results. | Verify compatibility of materials with printers and use high-quality DTF films from reputable brands. |

| Inadequate Preparation of Garment Surface | Not pre-treating or washing fabrics, leading to poor adhesion of transfers. | Ensure garments are properly cleaned and pre-treated before applying transfers. |

| Incorrect Printer Settings | Miscalibrated printer settings causing misalignments and wrong colors. | Calibrate printer settings based on the DTF film specifications. |

| Overlooking the Curing Process | Insufficient curing can lead to fading or cracking prints. | Follow manufacturer’s guidelines for curing temperatures and times. |

| Skipping Quality Control Steps | Rushing through inspections leading to defects in shipping. | Implement a thorough quality control process for each printed transfer. |

Summary

DTF Transfers are a pivotal technique in the printing industry that demand careful consideration and execution to achieve remarkable outcomes. From selecting the right materials to meticulous preparation of garment surfaces, every step in the DTF transfer process impacts the final result. Awareness of common mistakes, such as incorrect printer settings and neglecting the curing process, enables printers to enhance their product quality significantly. By adopting robust quality control measures and staying informed about best practices, businesses can ensure customer satisfaction and build a reputable brand in the competitive market. Investing time in avoiding these pitfalls leads not only to vibrant and durable prints but also to sustainable business growth.