When it comes to choosing the right printing method for custom apparel, understanding the differences between DTF vs DTG is essential for any business owner. DTF printing, or Direct-to-Film printing, is gaining popularity due to its versatility and cost-effectiveness, especially for various fabrics and promotional items. On the other hand, DTG printing, which stands for Direct-to-Garment, is renowned for producing high-quality prints with intricate details, particularly on cotton fabrics. As the market for textile printing continues to evolve, deciding between these two printing methods is crucial for meeting your customers’ needs and preferences. This comprehensive guide on DTF vs DTG will help you navigate the similarities and differences to find the best option for your business’s custom apparel needs.

In the realm of printing technologies, DTF and DTG represent two advanced options that cater to different market demands in custom apparel. Direct-to-Film printing offers a unique approach where designs are seamlessly transferred onto various materials, making it ideal for a diverse range of products, from clothing to promotional merchandise. Alternatively, Direct-to-Garment printing focuses on applying vivid images directly onto fabric surfaces, ensuring a soft feel and high-quality finish for fashion items. Both methods are pivotal in the textile printing landscape, each serving its purpose based on the project requirements and customer expectations. Understanding these printing techniques, their merits, and applications is vital for businesses looking to thrive in the competitive custom apparel industry.

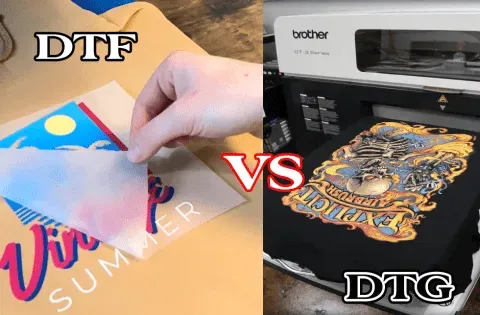

Key Differences Between DTF and DTG Printing

When it comes to choosing the right printing method for your business, understanding the key differences between Direct-to-Film (DTF) and Direct-to-Garment (DTG) printing is essential. DTF printing utilizes film and heat transfer to apply designs onto a variety of surfaces, which makes it highly versatile for various substrates, including non-fabric items. In contrast, DTG printing directly applies ink onto pre-treated garments, primarily focusing on high-quality prints that thrive on cotton and cotton-blend fabrics. This fundamental difference shapes not only the types of products each method excels at, but also the workflow considerations for businesses.

Another aspect to consider is the production process of each method. DTF printing is generally faster for large orders, providing significant cost savings for bulk production. It uses a relatively straightforward setup, allowing for quick transitions between designs. On the other hand, DTG printing requires more intricate preparation, including pre-treatment of the garment for optimal ink absorption. While DTG produces superior detail and color vibrancy, this comes at the cost of longer production times, especially for larger batches. Understanding these differences helps in making an informed decision based on your business’s specific needs.

Advantages of DTF Printing for Businesses

One of the standout advantages of DTF printing is its extreme versatility. Businesses can cater to a broader range of products – from apparel like t-shirts and hoodies to promotional items such as bags and decals. This capability allows for the customization required in today’s market, where personalization is key to customer satisfaction. In addition, the process employs a heat transfer method that not only adheres well to various materials, including polyester and blends, but also results in prints that are durable and resistant to wear.

Furthermore, DTF printing is often considered more cost-effective, especially for small to medium production runs. The method requires less ink consumption compared to conventional DTG setups, resulting in lower costs per item for businesses. This makes it an attractive option for startups or those with budget constraints looking to enter the custom apparel market. Speed is another major benefit; for bulk orders, DTF significantly cuts down on processing time, allowing businesses to fulfill orders more quickly and maintain customer satisfaction.

Benefits of DTG Printing for Custom Apparel

DTG printing shines in its ability to produce high-quality, intricately detailed prints that are perfect for custom apparel. This technology uses specialized inkjet processes that lay down water-based inks directly onto the fabric, especially cotton, which enhances the feel and look of the finished garment. Brands looking to offer premium, high-detail designs often find DTG to be the go-to option, as it allows for vibrant colors and sharp graphics that truly stand out.

Moreover, DTG printing aligns well with eco-friendly practices, as it primarily utilizes water-based inks that reduce environmental impact. As consumers become more environmentally conscious, having a printing method that utilizes sustainable practices can give a brand a competitive edge. Additionally, DTG allows for on-demand printing, which means businesses can minimize inventory costs and waste. This flexibility is especially valuable for companies wanting to test new designs or cater to niche markets without the risks associated with large print runs.

Production Speed Comparison: DTF vs. DTG

Production speed is a key factor when comparing DTF and DTG printing methods. DTF excels in bulk orders where speed is of the essence, thanks to its simplified printing process that minimizes time between setups. Once designs are ready, transferring them onto garments through heat presses can be executed very quickly, making DTF ideal for large-scale production runs. This speed capability is a significant advantage for businesses that need to meet tight deadlines without sacrificing quality.

Conversely, DTG printing, while producing exceptional detail and quality, can lag in production speed, particularly for larger jobs. The requirement of pre-treating garments adds extra time to the production process, which can become a bottleneck, especially when fulfilling multiple orders simultaneously. Businesses that prioritize quick delivery times while maintaining high quality may choose DTF over DTG as an operational strategy for increased efficiency.

Material Considerations in DTF and DTG Printing

When choosing between DTF and DTG printing, the type of material becomes a pivotal consideration. DTF printing’s versatility in applying designs to a wide array of fabrics, including cotton, polyester, and blends, as well as non-fabric surfaces, makes it an excellent choice for businesses targeting diverse markets. This adaptability allows for creative potential, enabling brands to offer a range of products that resonate with different consumer needs.

In contrast, DTG printing specializes predominantly in cotton and cotton-blend fabrics, which enables it to deliver superior print quality with vibrant colors. For brands centered around apparel with intricate designs, DTG’s focus on quality means compromise on material types isn’t preferred. Understanding which materials are best suited for each printing method helps businesses align their product offerings with customer expectations and trends.

Future Trends in DTF and DTG Printing

As technology progresses, both DTF and DTG printing methods are poised for significant advancements in the future. Innovations such as improved ink formulations and faster printing technologies are expected to enhance the efficiency and quality of both methods. For instance, the recent trends highlight manufacturers like Brother embracing both techniques, indicating a growing recognition of the strengths each method offers across various markets. Adapting to these trends can help businesses maintain a competitive edge.

Moreover, sustainability is becoming a focal point in the printing industry, with consumers increasingly favoring eco-friendly products. The water-based inks used in DTG printing align perfectly with these environmentally conscious trends, while DTF technology is also evolving to use more sustainable materials and processes. As both methods adapt to these consumer demands, businesses that capitalize on these trends will not only meet customer expectations but also contribute positively to the environment.

Frequently Asked Questions

What are the key differences between DTF and DTG printing methods?

The primary differences between DTF (Direct-to-Film) and DTG (Direct-to-Garment) printing methods lie in their applications and material versatility. DTF printing excels at transferring designs onto various substrates, while DTG printing is specifically designed for high-quality prints directly on cotton garments. If you’re looking for a versatile option that can handle diverse materials, DTF may be the better choice; however, for intricate and colorful apparel designs, DTG stands out.

Is DTF printing more cost-effective than DTG printing?

Yes, DTF printing is often more cost-effective than DTG printing, especially for small to medium production runs. It generally requires less ink and resources, making it ideal for businesses looking to minimize costs while producing high-quality custom apparel. Conversely, DTG printing usually involves higher initial setup costs and is more efficient for large orders that focus on detail and vibrant colors.

Which printing method, DTF or DTG, offers better durability for custom apparel?

DTF printing typically offers better durability for custom apparel compared to DTG printing. DTF prints are designed to resist cracking and fading over time, making them ideal for items that undergo regular wear and tear. While DTG prints can produce high-quality designs, they may not be as durable as DTF prints when exposed to frequent washing and use.

Can DTF printing be used on non-fabric materials unlike DTG printing?

Yes, one of the significant advantages of DTF printing is its versatility, allowing it to be applied to various non-fabric materials, whereas DTG printing is limited to textiles, primarily cotton fabrics. This makes DTF an excellent choice for printing on items like promotional bags and decals, expanding your customization options beyond just clothing.

What types of designs are best suited for DTF vs DTG printing?

DTG printing is highly suited for intricate and colorful designs due to its ability to render detailed graphics directly onto garments. On the other hand, DTF printing works well for simpler designs or those requiring less detail. If you specialize in complex artworks and vibrant visuals, DTG is advantageous; for broader, versatile projects, DTF is more appropriate.

How do production speeds compare between DTF and DTG printing methods?

In general, DTF printing outperforms DTG printing when it comes to production speeds, especially for bulk orders. DTF can handle higher volumes quickly, making it ideal for large runs. DTG may be slower due to its focus on quality, making it better for on-demand, low-quantity orders rather than mass production.

| Key Characteristics | DTF Printing | DTG Printing |

|---|---|---|

| Definition | Uses heat transfer by printing designs onto a film, which is applied to fabrics and other materials. | Directly prints designs onto garments using inkjet technology. |

| Advantages | – Versatile for various substrates – Cost-effective for small to medium runs – Faster production for bulk orders – Durable prints resistant to fading and cracking |

– High-quality, detailed prints – Eco-friendly due to water-based inks – No minimum order requirements – Maintains soft fabric feel |

| Best Applications | Ideal for custom decals, promotional items, and a variety of fabrics. | Best for high-quality t-shirts, hoodies, and detailed custom apparel. |

| Considerations | More suitable for diverse fabric types and simpler designs; better for larger volumes. | Perfect for intricate designs and on-demand printing for cotton materials. |

Summary

DTF vs DTG is a critical comparison for any business looking to optimize their printing processes and output. DTF printing offers flexibility and cost savings on bulk orders, making it a strong contender for brands requiring diverse and promotional products. Alternatively, DTG shines in creating high-resolution, intricate designs on apparel, thus catering to businesses focused on specific custom clothing needs. By carefully selecting the right method based on material type, production needs, and design complexity, businesses can effectively meet customer demands while positioning themselves for success in the competitive marketplace.