DTF transfers, or direct to film transfers, have emerged as a groundbreaking innovation in the world of fabric printing, capturing the attention of businesses and creatives alike. This advanced printing technology allows for high-quality custom DTF transfers that deliver vibrant designs with remarkable durability, setting a new standard in the industry. As we explore the future of fabric printing, it’s evident that the advantages of DTF printing are reshaping how creators and brands approach their textile designs. With the rise of DTF heat transfer methods, the ability to print on a diverse range of materials opens up exciting possibilities for customization and creativity. Join us as we delve deeper into how DTF transfers are revolutionizing the fabric printing landscape and what it means for the next generation of apparel.

The emergence of direct-to-film technology presents a transformative approach to fabric decoration. Often referred to as DTF printing, this method utilizes film transfers to apply intricate designs to various fabrics efficiently and effectively. As the apparel industry seeks quicker turnaround times and superior print quality, custom DTF transfers have quickly become the go-to solution for many decorators and brands. This innovative technique not only boasts a wide application range but also offers distinct advantages over traditional printing methods, making it a crucial player in the ever-evolving realm of textile production. Let’s explore the implications and benefits of this burgeoning technology in greater detail.

Understanding DTF Transfers: An Overview

Direct to Film (DTF) transfers represent a groundbreaking advancement in the fabric printing industry, offering an innovative alternative to traditional techniques. The process involves printing designs onto a special film that can then be transferred onto various fabrics using heat and pressure. This method contrasts sharply with others like sublimation printing, which is restricted to synthetic fabrics, making DTF a versatile solution that accommodates a broader range of materials. As such, it’s no surprise that many businesses are making the transition to DTF, recognizing its potential to enhance their product offerings.

Incorporating DTF transfers into the printing process allows for quicker production times and greater design flexibility. For custom designers and brands, this means they can respond rapidly to market trends and consumer demands without compromising quality. DTF technology provides a means to produce intricate, full-color designs that maintain vibrancy and durability, ensuring that printed fabrics not only look great but are also long-lasting. As a result, DTF is proving to be a transformative force in the fabric printing landscape.

DTF Printing Advantages: Why Choose DTF Transfers?

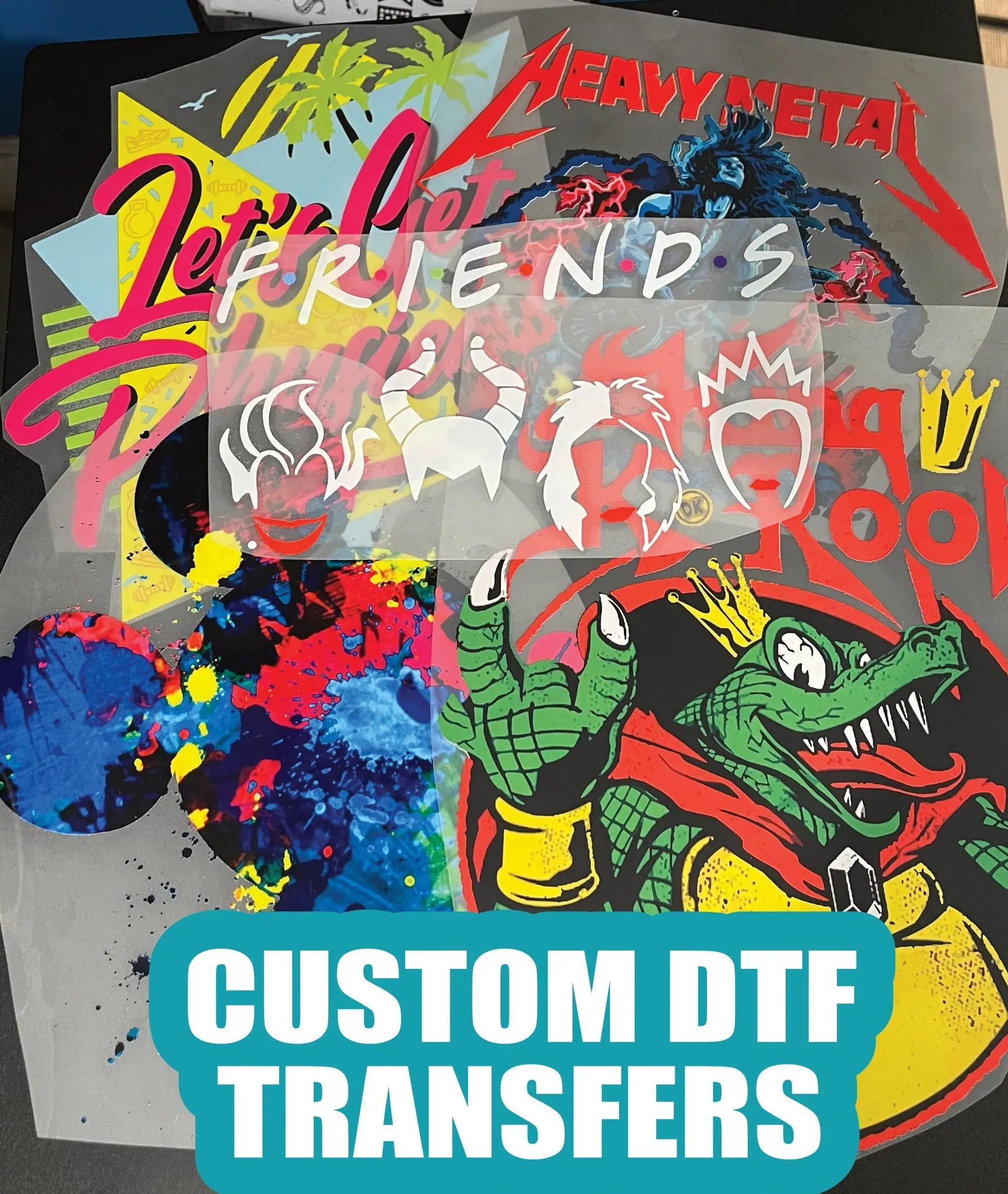

There are numerous advantages to utilizing DTF transfers over other printing methods. One of the primary benefits is the ability to print on a wide variety of fabrics, including cotton, polyester, and blends. This flexibility opens up new possibilities for apparel manufacturers and custom creators who want to diversify their product lines. Additionally, DTF transfers can produce vibrant colors and crisp details, adding a professional touch to any design. This quality is essential in the competitive fabric printing market, where aesthetics are paramount.

Another significant advantage of DTF printing is its efficiency and scalability. Businesses can produce prints quickly, allowing for rapid fulfillment of orders, which is increasingly important in today’s fast-paced retail environment. DTF technology also minimizes waste, as it requires fewer materials for setup compared to traditional methods like screen printing. This eco-friendly aspect not only appeals to environmentally conscious consumers but also reduces operational costs, making it a financially sound choice for print shops and manufacturers.

The Future of DTF Transfers in Fabric Printing

As the demand for customization and high-quality printing solutions grows, the future of DTF transfers looks promising. Continuous advancements in DTF technology are enhancing print quality, speed, and the range of applications, making it increasingly appealing for businesses of all sizes. With new machine designs and printing techniques emerging, we are likely to see even more options for creators and brands looking to elevate their fabric printing capabilities.

Moreover, the integration of Artificial Intelligence and automation in the production process foreshadows a shift toward even greater efficiency within the DTF printing sector. These innovations will likely decrease production times and streamline the customization process, allowing businesses to respond swiftly to consumer trends. As these technologies evolve, DTF transfers may very well solidify their position as the dominant method in the fabric printing industry.

Comparing DTF Transfers to Traditional Fabric Printing Methods

When comparing DTF transfers to traditional fabric printing methods, several key differences emerge that highlight DTF’s strengths. Traditional techniques such as screen printing often have larger setup costs and require more extensive preparation, whereas DTF printing is a simpler, more straightforward process. This simplicity allows for lower minimum order requirements, which is particularly beneficial for small businesses and independent creators looking to produce custom designs without significant financial risk.

Furthermore, DTF transfers excel in the complexity and richness of the designs they can produce. Unlike traditional methods that may fall short on smaller, intricate designs, DTF printing can replicate fine details and gradients effectively, resulting in a polished final product. This capability not only enhances the quality but also empowers creators to offer unique, high-definition designs that stand out in the market.

Exploring the Custom Transfer Experience with DTF Printing

The custom transfer experience afforded by DTF printing is a game-changer for many creators. Unlike previous methods that may limit design possibilities, DTF allows for greater creative freedom when producing intricate patterns and unique imagery. This makes it an attractive solution for artists and designers wanting to bring their visions to life with the highest fidelity possible. Businesses like DTFPrinter are capitalizing on this by offering user-friendly platforms that cater specifically to this demographic, ensuring that individuals can create high-quality transfers with ease.

Moreover, the focus on customization resonates strongly with modern consumers who value personalization in their purchases. With DTF transfers, creating custom designs for apparel has never been more accessible, thus tapping into a rapidly growing market segment. The ability for businesses and creators to offer bespoke products positions them well in a competitive landscape, while also enhancing customer satisfaction through tailored experiences.

Technological Innovations Driving DTF Transfer Growth

Recent technological innovations have been pivotal in propelling the growth of DTF transfers within the fabric printing industry. Advanced printing machines equipped with state-of-the-art software have enhanced the precision and quality of prints, allowing for a seamless transfer process that significantly reduces operational hiccups. This development is crucial for businesses aiming to establish themselves in a competitive marketplace, where speed and quality are essential to maintaining an edge.

In addition to machine advancements, the introduction of new materials and inks specifically designed for DTF printing has improved the overall performance of transfers. These innovations lead to increased durability and washability of prints, which customers highly value. As technology continues to evolve, we can expect even greater innovations that will further solidify DTF transfers as a cornerstone of modern fabric printing solutions.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or direct to film transfers, involve a printing process where designs are printed onto a special film, which is then heat transferred onto fabric. This innovative technique allows for vibrant colors and intricate designs, making it a top choice in the fabric printing future.

What are the advantages of DTF printing compared to traditional methods?

DTF printing advantages include its versatility on various fabric types and colors, quicker turnaround times, and the ability to produce high-quality results with detailed images. Unlike traditional printing methods, DTF allows for easy application and better durability of designs.

How do custom DTF transfers cater to the needs of designers and crafters?

Custom DTF transfers offer designers and crafters the ability to create unique, high-quality prints tailored to their specifications. This personalized approach helps meet individual creative needs while maintaining the quality and vibrancy that DTF printing technology delivers.

What is the significance of DTF heat transfer technology in fabric printing?

DTF heat transfer technology is significant because it simplifies the transfer process and increases the range of materials that can be printed on. This advancement leads to broader applications, making it a versatile choice in the ever-evolving fabric printing landscape.

Are DTF transfers suitable for commercial use?

Yes, DTF transfers are highly suitable for commercial use due to their efficiency, quality, and ability to handle large orders with intricate designs. They provide businesses with a competitive edge by minimizing production time while maximizing print quality.

What innovations are shaping the future of DTF transfers in fabric printing?

Innovations like the latest transfer technologies, such as Sawgrass’s VersiFlex, are reshaping the future of DTF transfers. These advancements enhance versatility and efficiency, enabling direct transfers onto various surfaces, thus expanding the potential market applications beyond traditional fabric.

| Key Developments in DTF Transfers | Description | Company | Impact | ||

|---|---|---|---|---|---|

| Emergence as a Leading Service | Sam’s DTF Transfers | Provides premium in-house services with enhanced speed and quality. | |||

| Innovative Product Launch | Insta Graphic Systems | Introduced products ensuring vibrancy and durability in prints, meeting consumer expectations. | |||

| Custom Transfer Experience for Creators | DTFPrinter | Offers tailored solutions for crafters and designers, enhancing user satisfaction. | |||

| New Transfer Technology | Sawgrass | Introduced VersiFlex technology for direct transfers without treatment, expanding usability. | |||

| Comparative Material Insights | Analysis | DTF offers versatility over sublimation, applying to more fabric types irrespective of color. | |||

Summary

DTF transfers are rapidly reshaping the landscape of fabric printing, providing innovative and customized solutions that are perfect for creators and businesses alike. As technology advances, the versatility and efficiency of DTF transfers allow for intricate designs and high-quality production that meets the evolving expectations of consumers. From the introduction of specialized services to advanced printing technologies, the future of fabric printing firmly lies in the hands of DTF transfers, making them an essential choice for anyone looking to thrive in the competitive printing market.