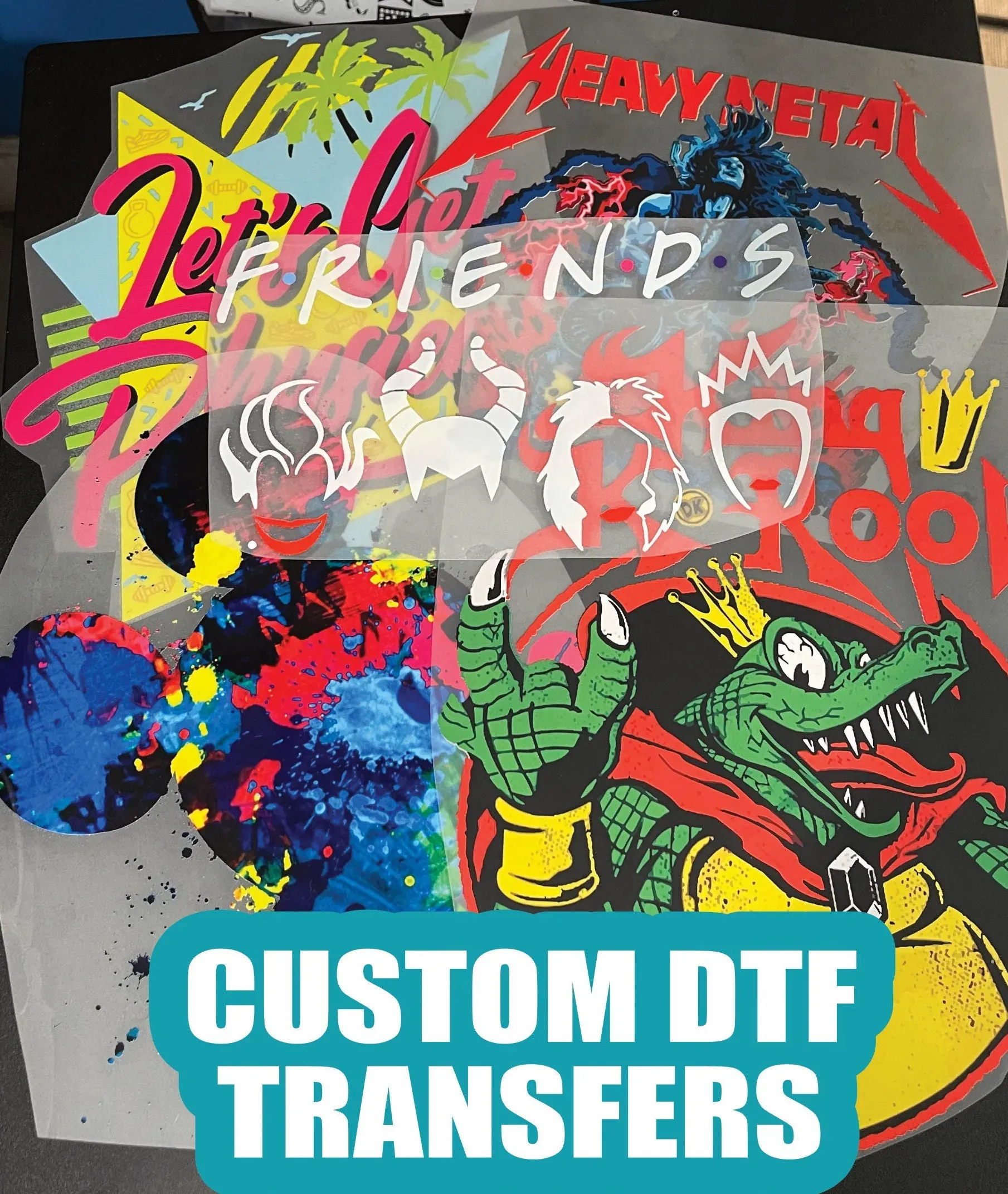

In the realm of custom apparel printing, **DTF Transfers** have emerged as a groundbreaking innovation, streamlining the way vibrant designs are showcased on fabric. Short for Direct-to-Film transfers, this cutting-edge technology facilitates the creation of stunning, durable prints that are perfect for both small businesses and seasoned professionals. Gone are the days of compromising on quality; with DTF, you can achieve eye-catching results that catch the eye and withstand the test of time. By utilizing advanced heat transfer technology, customers can enjoy the flexibility of applying vibrant prints onto various materials with remarkable ease. In this guide, we will delve into the intricacies of DTF transfers and discover how this method is revolutionizing the custom printing industry.

Also known as Direct-to-Film printing, DTF Transfers represent a significant shift in the paradigm of printing techniques used for creating custom apparel. This modern approach allows designs to be directly printed onto a film and then heat applied to various fabrics, particularly striking for those looking to produce vivid graphics that endure. The method ensures high color fidelity and long-lasting results, making it an ideal choice for promotional merchandise and fashion lines alike. By harnessing innovative heat transfer technologies, users can effectively transform their creative visions into tangible products with impressive durability. Whether you’re a business owner seeking to enhance your merchandise or a hobbyist exploring new artistic avenues, embracing direct-to-film printing can open up exciting possibilities in the world of fabric design.

Understanding Direct-to-Film Transfers

Direct-to-Film (DTF) transfers are quickly becoming a cornerstone in the realm of custom apparel printing. This innovative technology entails printing designs onto a specialized film, which can then be heat-transferred onto various fabric types. Unlike conventional printing techniques that can be limited by color or material, DTF allows for the creation of vibrant prints that can captivate audiences. The ease of use coupled with impressive color accuracy makes this a preferred choice for businesses and individual creators alike.

Moreover, DTF transfers are not only about aesthetic appeal; they also promise durability. Prints created using DTF technology are less prone to fading or cracking over time, ensuring that your designs remain as striking as the day they were printed. This longevity adds value to any apparel line, as customers appreciate products that withstand the test of time while maintaining their vibrancy.

The Advantages of DTF Transfers Compared to Other Techniques

One of the most significant advantages of DTF transfers is their cost-effectiveness. This method requires lesser upfront investment, especially for small to medium-scale operations, compared to traditional screen printing. This affordability allows new businesses or those expanding their product lines to utilize high-quality printing without the hefty costs often associated with other methods. The ability to print on demand further enhances its appeal, enabling creators to respond quickly to market trends.

Additionally, DTF transfers’s versatile application on a variety of fabrics—such as cotton, polyester, and blended materials—means businesses can broaden their offerings while maintaining quality. Each fabric type can be treated differently without compromising the vibrancy of the print. This adaptability is particularly beneficial for custom apparel brands looking to diversify their product catalog and cater to various customer preferences.

A Step-by-Step Guide to Creating Stunning DTF Transfers

Creating DTF transfers involves a straightforward yet meticulous process. Initially, the graphic design creation phase is crucial; designers must utilize high-resolution graphics to ensure clarity and sharpness in the final result. After designing, the artwork is printed onto a special DTF transfer film using a printer equipped with DTF inks, leading to rich color reproduction that draws the eye.

Once printed, covering the wet ink with hot-melt adhesive powder is the next vital step, followed by curing the adhesive with heat. This ensures that the ink adheres well to the film, setting the stage for a clean transfer to fabric. Proper application of heat with a heat press ensures that the vibrant prints are perfectly bonded to the material, creating durable designs that can handle everyday wear and tear.

Innovative Trends in DTF Printing

The DTF printing sector is evolving rapidly with advancements in technology that significantly improve the quality and efficiency of transfers. Innovative manufacturers like Insta Graphic Systems are launching products aimed at maximizing the vibrancy and durability of prints. Their new DFT lines are designed to provide superior fabric compatibility, allowing businesses to explore creative applications across a variety of materials.

Furthermore, companies are pushing the boundaries of what DTF technology can achieve. Faster production times and enhanced color fidelity are some of the latest developments, making it easier for businesses to meet the growing demand for custom apparel. As the market for personalized clothing continues to expand, embracing these innovations will be crucial for staying competitive.

Addressing Challenges in DTF Printing

While the benefits of DTF transfers are impressive, potential challenges must be recognized. For small businesses, the initial setup costs associated with DTF printers and materials can be significant. Understanding the investment required and planning effectively can help mitigate this challenge as they scale their operations.

Moreover, mastering the DTF printing process necessitates a learning curve. Factors such as heat settings and material selection can greatly influence the final output. Practicing and refining these elements not only ensures high-quality results but also enhances the overall efficiency of the printing process, leading to improved customer satisfaction.

Tips for Successful DTF Transfer Applications

To maximize the potential of DTF transfers, a few critical tips can lead to greater success in application. First, the selection of compatible fabrics plays a significant role in print quality. Testing various substrates can provide insights into what works best with your designs, ensuring high-quality transfers that perform as expected.

Secondly, careful attention to temperature settings is essential. Each fabric responds differently to heat; therefore, experimenting to find the optimal range is key in avoiding damage while enhancing adherence of the print. Alongside regular maintenance of the printing equipment, these practices can lead to consistent production of vibrant, durable prints that meet clients’ expectations.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, involve printing a design onto a special film, which is then heat transferred onto fabric. This method allows for vibrant prints and enhances the durability of custom apparel, making it a popular choice among businesses and DIY enthusiasts.

What advantages do DTF transfers offer over traditional printing methods?

DTF transfers provide several advantages, including vibrant colors, durability against fading and cracking, and versatility across various materials like cotton and polyester. These features make DTF technology a game-changer in custom apparel printing.

How do DTF transfers ensure color fidelity in custom designs?

DTF transfers utilize high-quality DTF inks and a specialized printing process that preserves color accuracy. This ensures that the colors on the final printed apparel match those displayed on digital screens, crucial for effective branding and customer satisfaction.

Can DTF transfers be applied to various fabric materials?

Yes, DTF transfers are compatible with a wide range of fabrics, including cotton, polyester, and their blends. This versatility makes DTF technology ideal for diverse custom apparel printing projects.

What factors should I consider for successful DTF printing?

For successful DTF printing, consider the compatibility of fabrics with the DTF process, optimal temperature settings for heat transfer, and regular maintenance of your printing equipment to avoid operational issues.

Are DTF transfers a cost-effective solution for small businesses?

Yes, DTF transfers can be a cost-effective solution for small to medium-sized printing orders. They require minimal setup compared to traditional methods, allowing for quicker turnarounds and lower production costs.

| Feature | Description |

|---|---|

| What Are DTF Transfers? | A printing method where designs are transferred from film onto fabric using heat. |

| Vibrant Colors | Produces rich and vivid colors that stand out. |

| Durability | Resistant to fading, cracking, or peeling, ensuring a long-lasting finish. |

| Versatile Application | Can be used on various materials like cotton and polyester. |

| Cost-Effective | Lower-cost alternative for small to medium-sized orders. |

| Quick Turnaround | Advancements allow for same-day service for urgent projects. |

| Color Accuracy | Produces high-fidelity colors matching what is seen on the screen. |

| Innovations | Companies like Insta Graphic Systems are enhancing quality and efficiency. |

| Challenges | Initial setup costs and mastering printing processes may pose barriers. |

Summary

DTF Transfers have emerged as a revolutionary solution in custom apparel printing, offering vibrant colors, durability, and versatility which are crucial for business success. As advancements continue within the DTF technology sector, and with industry leaders pushing the boundaries of what is possible, embracing DTF Transfers could significantly enhance the quality of prints produced by businesses and DIY enthusiasts alike. The technology not only meets the demands of today’s market but also promises to evolve further, ensuring that high-quality customization remains accessible.