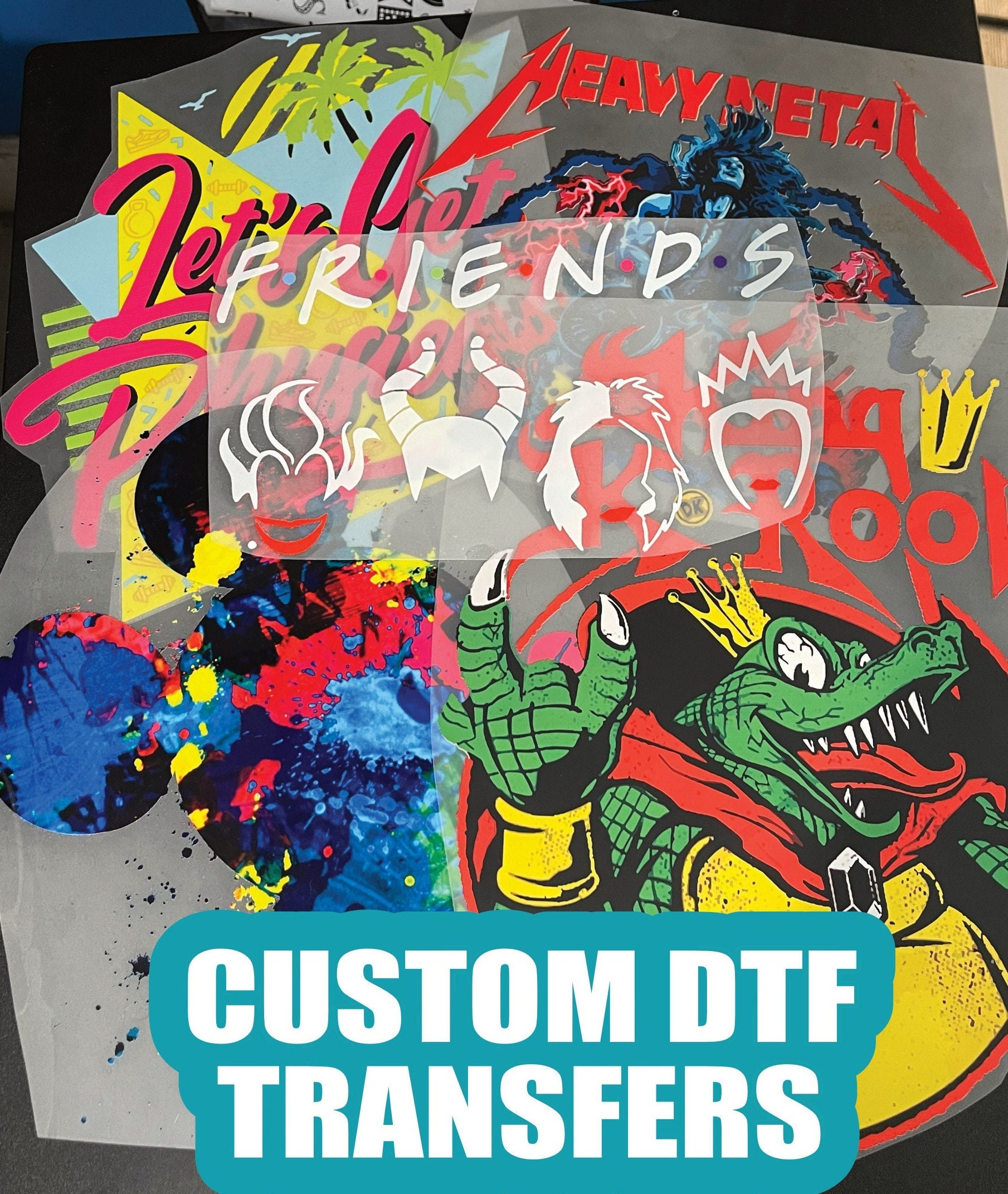

DTF Transfers, or Direct to Film transfers, have quickly gained recognition as a revolutionary method for producing high-quality graphics on various fabrics. This innovative printing technique offers a wide array of vibrant colors and exceptional durability, making it the go-to choice for anyone looking to create custom apparel, bags, and more. However, many users encounter significant challenges that can spoil their printing ambitions, leading to a final product that falls short of expectations. In this article, we will delve into **common DTF transfer mistakes** to help you bypass these pitfalls and provide valuable **DTF printing tips** to ensure your designs come out flawlessly every time. By mastering essential **DTF application techniques**, you’ll boost your printing success and elevate your craftsmanship to new heights.

When discussing DTF Transfers, it’s essential to recognize the broader spectrum of techniques involved in Direct to Film printing. This creative process encompasses a range of methods aimed at transferring intricate designs onto fabric surfaces, making it a favorite among designers and businesses alike. However, even seasoned users can fall victim to **common DTF errors** that could compromise their final output. By understanding the intricacies of DTF application, and adopting effective DTF printing strategies, one can significantly enhance the quality of custom graphics and ensure a seamless experience. In the following sections, we will uncover the typical pitfalls and offer insightful tips for a successful DTF journey.

Understanding DTF Printing Basics

Direct to Film (DTF) printing is a modern technique that has gained significant popularity in the custom apparel industry due to its ability to produce vibrant and durable prints. Unlike traditional printing methods, DTF allows for a wider variety of fabrics and surfaces, making it an attractive option for businesses looking to expand their product offerings. The process involves printing designs onto a special transfer film, which is then heat applied to the fabric. This method not only ensures sharp, detailed images but also offers flexibility in color and design, allowing for intricate patterns and textures.

To maximize the effectiveness of DTF printing, understanding its components is crucial. The inks used in DTF machines are specially formulated for optimal adhesion and longevity. Additionally, the choice of transfer film and the printer settings can greatly influence the final outcome. By familiarizing oneself with these elements, users can avoid common pitfalls and ensure a higher standard of print quality that stands the test of time.

Frequently Asked Questions

What are common DTF transfer mistakes to avoid?

Some common DTF transfer mistakes include incorrect printer settings, poor material selection, inadequate pre-printing preparation, improper application techniques, and lack of quality control. Avoiding these pitfalls ensures vibrant and durable prints.

How can I improve my DTF printing results?

To improve DTF printing results, ensure correct printer settings like resolution and color profiles, choose high-quality materials for better adhesion, and follow proper DTF application techniques, including temperature, pressure, and quality control measures.

What are the best materials for DTF transfers?

The best materials for DTF transfers include fabrics like cotton, polyester, and blends that provide good adhesion. It’s essential to avoid fabrics like nylon, which may not respond well to DTF printing techniques.

What are some effective DTF application techniques?

Effective DTF application techniques involve using the right heat settings and pressure as per manufacturer guidelines. Properly preheating the transfer and ensuring even pressure during application are critical for successful transfers.

How can I avoid common DTF printing errors?

Avoid common DTF printing errors by checking printer settings, preheating the transfer film, selecting suitable materials, conducting sample tests, and performing regular maintenance on your printing equipment.

What should I do if my DTF transfer is peeling or cracking?

If your DTF transfer is peeling or cracking, ensure you are using compatible materials, check your application temperature and pressure, and assess for any issues during pre-print preparation and post-print quality control.

| Common Mistakes | Key Points |

|---|---|

| Incorrect Printer Settings | Ensuring correct resolution, color profiles, and ink settings. |

| Material Selection | Choosing the right fabric to ensure proper adhesion and durability. |

| Inadequate Pre-Printing Preparation | Preheating film and cleaning printheads to ensure quality. |

| Improper Application Techniques | Following correct temperature and pressure settings during heat application. |

| Lack of Quality Control | Conducting post-print inspections and sample testing for quality assurance. |

| Storage Issues | Controlling moisture and temperature during storage to prevent material degradation. |

| Failing to Test | Running test prints to evaluate quality before large orders. |

| Neglecting Maintenance | Regularly cleaning equipment and addressing issues promptly for optimal performance. |

Summary

DTF Transfers are a revolutionary method in fabric printing that can deliver beautiful, long-lasting designs if approached correctly. To maximize the efficacy of DTF transfers, it’s crucial to be aware of common pitfalls in the printing process. From ensuring accurate printer settings and selecting compatible materials, to maintaining strict quality control and conducting essential test runs, each step plays a significant role in achieving desired results. By avoiding these frequently made mistakes and prioritizing proper preparation and maintenance, businesses can leverage the advantages of DTF transfers to produce exceptional products that stand the test of time.