DTF transfer paper is an essential component for anyone venturing into the world of Direct-to-Film (DTF) printing, a technique that has rapidly become a favorite among custom garment printers. Selecting the right DTF transfer paper significantly impacts the quality of your prints, making it critical to understand the various factors involved in making your choice. From paper thickness to coating quality, each aspect plays a crucial role in ensuring vibrant, durable images that last. As you explore the best DTF transfer paper options available, consider how different transfer paper types can affect your printing outcomes. This guide will provide you with insights needed to choose DTF transfer paper that meets your specific project needs, enhancing the overall execution of your DTF printing endeavors.

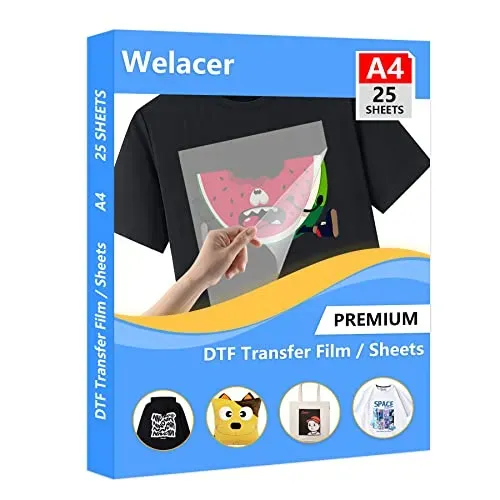

When diving into the realm of Direct-to-Film printing, you’ll often encounter various descriptors for materials like DTF transfer paper, including film transfer sheets and heat transfer film. These alternatives refer to the same innovative product designed to facilitate high-quality designs onto garments, making them a popular choice for fabric decoration. As you navigate the landscape of printing supplies, recognizing different terms for DTF materials can simplify your research and broaden your sourcing options. Each term, whether it’s heat transfer film or film transfer sheets, refers to the beautiful capability of transferring detailed designs onto fabrics with ease and precision. In this context, selecting the right film is just as important as understanding the diverse DTF printing options available to enhance your creative projects.

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing is a revolutionary technique in the garment printing landscape, offering a highly efficient and customizable solution for apparel decorators. Unlike traditional methods, DTF printing involves printing designs onto special transfer film, which is then heat pressed onto textiles. This process allows for a wide variety of fabric types to be printed, from cotton to polyester, making it incredibly versatile. The ability to use bright colors and fine details in prints is a significant advantage, leading to high-quality results that are both visually appealing and durable.

As DTF technology continues to evolve, it is enhancing the capabilities of those in the custom printing market. Manufacturers are innovating their approaches to improve transfer papers, inks, and printing equipment. The introduction of faster print speeds and lower cost per transfer has made DTF an attractive option for businesses looking to expand their offerings. Understanding the dynamics of DTF printing helps in choosing the right components, particularly when selecting DTF transfer paper, as different paper types can yield varying results.

Choosing the Best DTF Transfer Paper

Selecting the best DTF transfer paper is essential for achieving optimal printing outcomes. Quality should always be prioritized; thicker papers typically provide better durability and image clarity compared to lighter options. Brands such as Prisma and iColor have garnered positive feedback in the community for their top-tier products that cater specifically to DTF printing. When choosing paper, consider one that can effectively withstand the heat of the transfer process while maintaining a vibrant and clear print.

Another critical factor when choosing DTF transfer paper is its compatibility with specific printer models and inks. Different DTF printers require specific transfer paper types for optimal performance. It’s advisable to consult your printer’s manual or online resources to determine the right specifications. Matching your DTF inks with the appropriate transfer paper can greatly impact the final print quality, ensuring that the colors are vivid and that the details remain sharp.

Identifying Transfer Methods for DTF Printing

The method of transferring designs to your fabric significantly impacts the quality of the finished product in DTF printing. Most successful DTF transfers rely on a heat press, which applies both pressure and heat to transfer the ink from the paper to the material. The type of DTF transfer paper used can dictate the ideal temperature and press time settings required for a smooth transfer. Variations in methods mean certain papers are optimized for specific conditions, so it’s vital to choose a paper that aligns with the heat press you’re using.

For instance, some DTF transfer papers require lower temperatures and shorter press times, while others might perform best with higher settings. Always refer to the manufacturer’s guidelines for the paper you choose to ensure you’re achieving the best results. Experimenting with different temperature and pressure settings can also yield better outcomes, as even slight variations can affect how well the transfer adheres and how vibrant the colors appear on the final product.

Evaluating Project Requirements for DTF Transfers

When embarking on a DTF printing project, it’s essential to evaluate the specific requirements of your design. Different fabrics, project sizes, and intended uses can dictate the type of DTF transfer paper you should select. For example, if you’re working with soft fabrics or need a particular texture, certain transfer papers are better suited for those specifications. Similarly, if your project involves printing on dark materials or requires a high level of opacity, you’ll want to ensure that you’re selecting an appropriate paper that can handle such needs.

Additionally, consider whether your design will benefit from a glossy or matte finish, as this can also be influenced by the choice of transfer paper. While some papers are designed to create a high-gloss look, others may produce a more subdued finish. Assessing these project requirements in advance not only assists in choosing the right DTF transfer paper but also enhances the overall satisfaction with the final product.

Exploring DTF Transfer Paper Types

Exploring the various types of DTF transfer papers available in the market is crucial in order to pinpoint the best fit for your specific print job. Among the different types, there are clear, opaque, and specialty papers designed for unique applications, each with their own advantages and intended uses. Clear transfer papers are beneficial for designs requiring a transparent background, allowing the base fabric color to effectively show through, while opaque papers are ideal for printed images that demand bold colors, especially on dark garments.

Specialty DTF transfer papers, such as those specifically designed for stretchy fabrics or those with unique textures, can significantly enhance the application process. These papers are engineered to adhere well and maintain flexibility, which is especially important for items like performance apparel. When selecting a type, be sure to consider the specific requirements of your project, including the fabric type and the desired visual outcome.

Recent Innovations in DTF Transfer Technology

The DTF transfer printing industry is experiencing rapid innovations that continuously improve the quality and versatility of the process. Recent advancements include the development of heat-resistant DTF transfer papers that enhance the durability and vibrancy of prints. Brands are focused on refining the transfer paper formulations, ensuring that users receive products that not only deliver superior results but are also user-friendly and cost-effective. Innovations in this field aim to meet the growing consumer demands for high-quality custom apparel.

Together with advancements in transfer paper, the integration of improved printer technologies has revolutionized the DTF printing workflow. Newer printers are being designed to complement the evolving transfer papers, allowing for faster printing speeds and more accurate color representation. As a result, users can achieve high-quality prints with fewer errors. Staying updated with these advancements allows you to better select your materials, including the best DTF transfer paper, and to maximize your printing efficiency.

Frequently Asked Questions

How do I choose DTF transfer paper for my printing projects?

When choosing DTF transfer paper, consider factors like paper quality, compatibility with printers, and ink types. Opt for thicker papers with a smooth coating for better print quality. Make sure the paper is compatible with your printer and the DTF inks you are using. Additionally, check for specific transfer methods tailored to your heat press settings.

What is the best DTF transfer paper for vibrant prints?

The best DTF transfer paper for vibrant prints is typically one that is opaque, allowing colors to pop against dark fabrics. Brands like Prisma and iColor are known for producing high-quality papers that enhance color vibrancy and durability, making them popular choices in the custom garment printing industry.

Are there different types of transfer paper available for DTF printing?

Yes, there are various transfer paper types available for DTF printing, including opaque and transparent options. Each type serves different project requirements, such as fabric type and design visibility. It’s essential to choose the right transfer paper type based on the end-use of your prints.

What factors affect the performance of DTF transfer paper?

The performance of DTF transfer paper is influenced by several factors, including paper thickness, coating quality, printer compatibility, and the type of DTF ink used. It’s also important to follow the recommended heat press settings for optimal transfer results.

How does DTF printing compare to other transfer methods?

DTF printing is becoming increasingly popular due to its versatility and high-quality results compared to other methods like screen printing or heat transfer vinyl. DTF transfer paper allows for softer prints on various fabric types, delivering vibrant colors and intricate designs with excellent durability.

Where can I find reliable DTF printing options and resources?

Reliable DTF printing options and resources can be found on platforms like Transfer Express and Printavo. These websites offer guides, product reviews, and tips to enhance your understanding of DTF transfer paper and printing processes for improved results.

| Consideration | Description |

|---|---|

| Paper Quality | Opt for thicker papers (100gsm to 130gsm) for best image quality and durability. Ensure smooth coating for better ink adherence. |

| Compatibility with Printers | Check that your selected paper works with your printer’s specifications for optimal print results. |

| Ink Type | Verify the compatibility of the DTF transfer paper with the specific types of DTF inks you will be using. |

| Transfer Method | Understand the heat press settings for the paper to ensure successful transfer results based on temperature and press time. |

| Visibility | Choose between transparent, semi-transparent, or opaque papers based on your design needs and color vibrancy required. |

| Project Requirements | Assess specific project needs such as fabric type, colors, and textures for selecting the most appropriate paper. |

Summary

DTF transfer paper plays a pivotal role in the outcome of your printing endeavors. Choosing the right DTF transfer paper involves careful consideration of various factors, including paper quality, compatibility with printers, ink type, and specific project requirements. By understanding these key aspects, you can enhance the quality of your prints and ensure impressive results. With ongoing advancements in the DTF printing technology and innovative formulations of DTF transfer paper, users can look forward to even more options, empowering them to produce high-quality, vibrant designs in the years to come.