In the fast-evolving world of printing technologies, the DTF Gangsheet Builder serves as a revolutionary tool that enhances both printing efficiency and quality. Direct-to-Film (DTF) printing has become a preferred choice for professionals aiming to produce vibrant, high-quality prints on various textiles. With its ability to efficiently organize multiple designs onto a single film sheet, the DTF Gangsheet Builder minimizes waste and accelerates the printing process. This innovative software not only optimizes the layout of designs for maximum output but also ensures that the end product boasts impressive colors and details. As businesses strive to keep pace with consumer demands for personalization and customization, implementing a DTF Gangsheet Builder could be the key to elevating standards in print quality.

Direct-to-Film printing, often referred to as DTF printing, utilizes advanced techniques to create vibrant designs on fabrics. At the heart of this process lies gangsheet software, specifically the DTF Gangsheet Builder, which plays a critical role in organizing and maximizing print runs. By efficiently laying out multiple designs on a single transfer sheet, this tool enhances printing efficiency and reduces material wastage. In essence, the DTF Gangsheet Builder is not just about saving time; it’s also about maintaining superior print quality that meets the evolving needs of garment and textile businesses. As the demand for high-quality prints continues to rise, understanding the capabilities of such groundbreaking tools becomes increasingly vital for professionals in the industry.

The Advantages of Using DTF Printing for Textile Applications

DTF printing has revolutionized the textile industry by providing unmatched flexibility and quality. This innovative process allows for the quick transfer of vibrant, detailed designs directly onto various fabrics. Unlike traditional methods, DTF can handle complex graphics with ease, delivering high-resolution prints that are both durable and visually appealing. Designers looking for versatility find DTF to be an ideal choice as it accommodates a wide range of substrates, enabling them to expand their product offerings.

Additionally, DTF printing stands out due to its efficiency in both small and large print runs. By utilizing specialized transfer films, printers can achieve exceptional print quality without the need for extensive setups or lengthy drying times. This not only accelerates production timelines but also significantly reduces costs associated with misprints and wasted materials, making DTF a smart solution for businesses aiming to optimize their printing processes.

Enhancing Productivity with DTF Gangsheet Builders

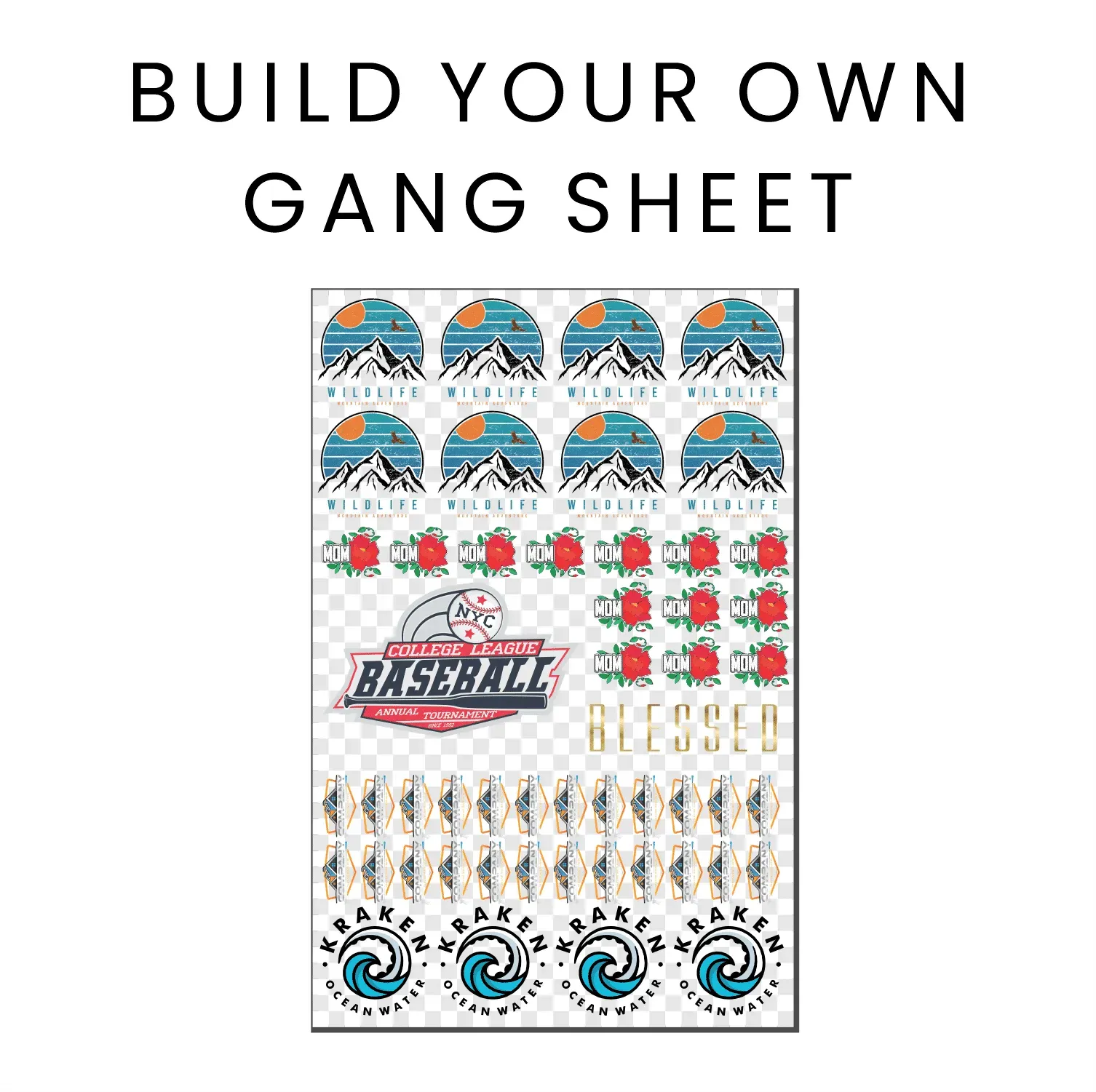

DTF gangsheet builders play a critical role in maximizing the output of DTF printing systems. By allowing multiple designs to be arranged on a single sheet of transfer film, these tools minimize waste and improve overall efficiency. The ability to fit various designs intelligently into available space leads to substantial savings on both materials and printing time, which is essential for businesses with tight deadlines.

The ease of use offered by modern gangsheet builders further boosts productivity. With user-friendly interfaces and automated layout options, even those new to DTF printing can quickly become proficient. This not only streamlines workflows but also helps maintain high print quality standards by ensuring designs are optimally aligned on the film.

Innovations Driving the DTF Printing Industry

Recent advancements in DTF technology are reshaping the landscape of textile printing, particularly through innovations in gangsheet builders. These tools are increasingly equipped with real-time preview capabilities, allowing users to visualize their designs before commencing production. Such features help reduce errors and ensure that the final output meets the desired specifications, enhancing the reliability of DTF printing.

Moreover, the integration of automated design layouts has introduced a new level of efficiency. As these builders can quickly rearrange designs for optimal placement on gang sheets, printers can fulfill orders faster and with greater accuracy. This focus on innovation is essential for businesses that aim to stay competitive in an ever-evolving market driven by consumer demand for personalized and high-quality prints.

Market Trends Shaping DTF Printing

The DTF printing market is on an upward trajectory, fueled by a surge in demand for vibrant and customizable textile solutions. The trend indicates that businesses are increasingly adopting DTF technology due to its cost-effectiveness and ability to produce intricate designs with minimal setup time. As more companies recognize the advantages of DTF over traditional methods, the market is witnessing an influx of investment aimed at enhancing printing capabilities.

Furthermore, the versatility of DTF printing allows for customization that appeals to modern consumers who seek personalized products. This demand for unique prints is driving the growth of the DTF market, encouraging printers to explore new applications and collaborations. As a result, industry players are continuously evolving their offerings to satisfy the diverse needs of their clients, establishing a vibrant ecosystem within the textile printing community.

Cost Efficiency: A Key Benefit of DTF Gangsheet Builders

One of the primary benefits of utilizing a DTF gangsheet builder is the significant cost efficiency it offers to businesses. By optimizing the layout of designs on a single sheet of transfer film, printers reduce material waste and lower ink costs, ultimately leading to substantial savings. This is particularly advantageous for companies that frequently produce small runs, as every inch of film is used effectively.

Additionally, the reduction in waste directly impacts a company’s bottom line. As businesses strive to remain competitive, implementing a gangsheet builder not only improves operational efficiencies but also enhances profitability by minimizing unnecessary expenses. This focus on cost-saving practices is critical for sustaining long-term success in the printing industry.

Quality Control and the Role of DTF Gangsheet Builders

Quality control is paramount in the printing industry, and DTF gangsheet builders contribute significantly to this aspect. These tools assist in organizing designs accurately on the gang sheet, which helps to prevent misprints and maintain high-quality outputs. By ensuring that each design is properly aligned, businesses can achieve consistency and precision in their printed products, further enhancing customer satisfaction and brand reputation.

Moreover, the ability to preview designs before printing allows for an additional layer of quality assurance. With real-time adjustments and layout checks, businesses can identify and correct potential issues before they result in costly errors, ensuring that every print meets the highest standards. This commitment to quality not only benefits the end customer but also solidifies a company’s position as a reliable player in a competitive marketplace.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it enhance printing efficiency?

A DTF gangsheet builder is a software tool designed to optimize the layout of multiple designs onto a single transfer film for Direct-to-Film (DTF) printing. By maximizing the use of film and minimizing wasted space, it significantly enhances printing efficiency, allowing for quicker production times and reduced material costs.

How does the DTF gangsheet builder improve print quality?

The DTF gangsheet builder ensures precise alignment of multiple designs, which helps maintain consistency in print quality. With automated layouts and real-time previews, users can avoid misprints and achieve high-quality, photo-realistic images that are vibrant and durable across various substrates.

Why is DTF printing preferred for small print runs?

DTF printing, coupled with a DTF gangsheet builder, is ideal for small print runs because it allows for quick customization and efficient use of materials. This system reduces operational costs compared to traditional methods, making it a favored choice for businesses that need flexibility and quality in their printing projects.

What are the latest innovations in DTF gangsheet builders?

Recent innovations in DTF gangsheet builders include user-friendly interfaces, automated design layouts, enhanced compatibility with design software, and real-time preview features. These advancements streamline the workflow, making it easier for users to achieve optimal layouts that maximize film usage and improve overall printing performance.

How can businesses benefit from investing in a DTF gangsheet builder?

Investing in a DTF gangsheet builder can lead to significant cost efficiency, increased speed and productivity, and improved quality control. By reducing material waste and accelerating production times, businesses can better meet customer demands while maintaining high standards in print quality.

Are there any leading brands offering DTF gangsheet builders in the market?

Yes, notable brands like Epson and Brother are leading the market with their innovative DTF gangsheet builders. These companies continuously update their technologies, incorporating advanced features that enhance the DTF printing experience and help businesses stay competitive in the evolving printing landscape.

| Key Point | Details |

|---|---|

| Introduction to DTF Printing | DTF printing offers versatile and efficient solutions for textile applications, allowing for vibrant prints on various fabrics. |

| What is DTF Printing? | A method of printing designs on transfer film, adhering them to fabric through heat, resulting in photo-realistic and durable images. |

| Understanding Gangsheet Builders | A tool for optimizing print runs by efficiently organizing multiple designs onto a single film sheet, minimizing waste and enhancing productivity. |

| Recent Innovations | Features like automated layouts, user-friendly interfaces, enhanced compatibility with design software, and real-time previews. |

| Market Trends | A growing demand for cost-effective and high-quality printing solutions, particularly for personalization and customization. |

| Benefits of Using DTF Gangsheet Builder | Cost efficiency, speed and productivity, quality control, and staying innovative are significant advantages. |

| Popular Brands | Epson and Brother are leading brands enhancing their DTF technologies alongside emerging startups. |

Summary

The DTF Gangsheet Builder is a transformative tool that enhances the quality and efficiency of printing processes in the textile industry. By leveraging this innovative technology, businesses can optimize their print runs, reduce waste, and improve overall productivity. As the demand for personalized fabrics increases, the ability to create high-quality prints using DTF printing methods, paired with the strategic capabilities of gangsheet builders, positions companies to excel in a competitive market. Staying ahead with the latest advancements not only improves product quality but also reinforces a brand’s reputation as a leader in textile printing.